New Crank

-

Anyone used or heard of these ? Will it be cheaper to buy new than get the original refurbished?

-

Anyone used or heard of these ? Will it be cheaper to buy new than get the original refurbished?

@Scootjockey Looks very nice, expect to pay some import duties here.

I bought a forged connecting rod from RRD Preparation during the pandemic. Took very long to arrive, no fault of RRD Preparation and they were really good at getting back to my emails. At the time they didn't support PayPal so it was literally just wiring some money to them and hoping the item arrives, which it did!

-

@Scootjockey Looks very nice, expect to pay some import duties here.

I bought a forged connecting rod from RRD Preparation during the pandemic. Took very long to arrive, no fault of RRD Preparation and they were really good at getting back to my emails. At the time they didn't support PayPal so it was literally just wiring some money to them and hoping the item arrives, which it did!

-

Anyone used or heard of these ? Will it be cheaper to buy new than get the original refurbished?

@Scootjockey I bought one of these Top Racing cranks from PJME. The bottom and went together well and I had to use a crank puller tool to fit it into the LH main bearing like the Yamaha manual says so critical dimensions would appear to be as they should be. Here's the link to the puller which comes as a set with a case splitting tool, half the price of Yambits etc.:

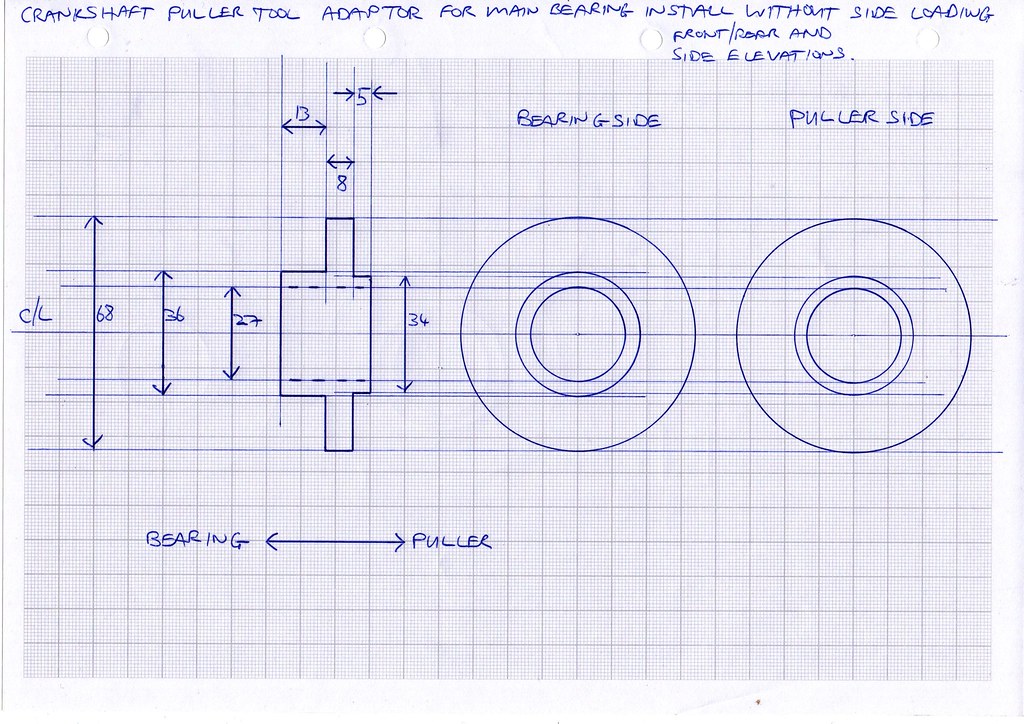

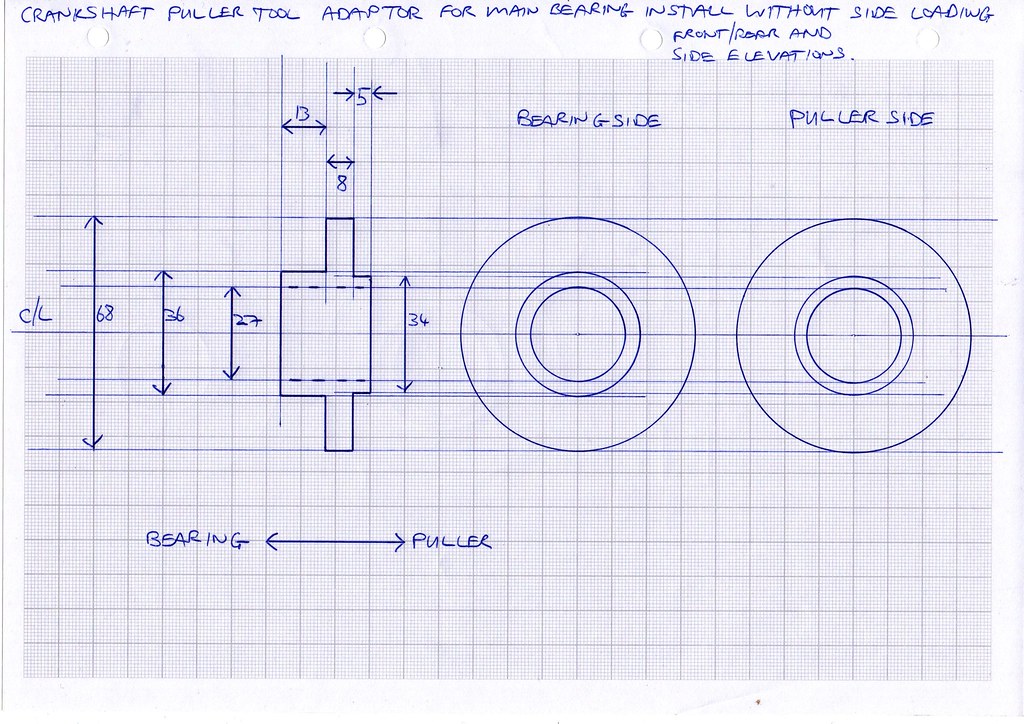

To avoid transmitting a side load through the main bearing (which will shorten its working life considerably as ballraces don't like this kind of treatment) I also had this adapter made (pics taken using the original crank for test fitting):

The only issues I had were:

The threads for the primary/flywheel nut aren't as well finished as on a genuine crank meaning I had to purchase a couple of M12 dies to lightly chase them before the new OEM Yamaha nuts would screw on smoothly using fingers. Not drastic, the tool didn't feel like it was doing very much and I think it would have been fine to just screw them on with a socket but I'm quite finicky about stuff like that.

Woodruff key grooves were a little tight (as they should be) so I needed to gently clean up the flywheel side with a needle file and lightly tap the new OEM key in with a toffee hammer.

My 30-year-old flywheel was a little rusty inside the taper so I lapped it and the crank into each other using some fine valve grinding paste (PJME said they commonly do this when I asked them first). Fit the crank seal before doing this to protect the main bearing, and make sure you clean it all off the crank/flywheel thoroughly before the first startup!!

I haven't tested the crank yet so can't comment on long-term reliability but I'm pretty impressed with mine so far.

I think if you buy from PJME it will cost about the same as a refurb depending what level of conrod kit you choose but the main selling point for me was it's brand new, trued and ready to fit; I once had a KX250 crank rebuilt and the web diameter where the main bearings fit were sufficiently worn to allow the crank to rotate inside the main bearing inner races. I got a local machinist to knurl these surfaces to make them slightly proud, then pressed the mains on with loads of high-strength Loctite bearing fit on the advice of a well-respected MX rider/mechanic but the bottom end lasted about 5 minutes before it happened again.

Also I bought some Athena 56mm top end kit pistons from RRD Preparation (they sell the A, B and C dimension pistons) and they turned up pretty quickly so I'd be happy to order from them again.

-

@Scootjockey I bought one of these Top Racing cranks from PJME. The bottom and went together well and I had to use a crank puller tool to fit it into the LH main bearing like the Yamaha manual says so critical dimensions would appear to be as they should be. Here's the link to the puller which comes as a set with a case splitting tool, half the price of Yambits etc.:

To avoid transmitting a side load through the main bearing (which will shorten its working life considerably as ballraces don't like this kind of treatment) I also had this adapter made (pics taken using the original crank for test fitting):

The only issues I had were:

The threads for the primary/flywheel nut aren't as well finished as on a genuine crank meaning I had to purchase a couple of M12 dies to lightly chase them before the new OEM Yamaha nuts would screw on smoothly using fingers. Not drastic, the tool didn't feel like it was doing very much and I think it would have been fine to just screw them on with a socket but I'm quite finicky about stuff like that.

Woodruff key grooves were a little tight (as they should be) so I needed to gently clean up the flywheel side with a needle file and lightly tap the new OEM key in with a toffee hammer.

My 30-year-old flywheel was a little rusty inside the taper so I lapped it and the crank into each other using some fine valve grinding paste (PJME said they commonly do this when I asked them first). Fit the crank seal before doing this to protect the main bearing, and make sure you clean it all off the crank/flywheel thoroughly before the first startup!!

I haven't tested the crank yet so can't comment on long-term reliability but I'm pretty impressed with mine so far.

I think if you buy from PJME it will cost about the same as a refurb depending what level of conrod kit you choose but the main selling point for me was it's brand new, trued and ready to fit; I once had a KX250 crank rebuilt and the web diameter where the main bearings fit were sufficiently worn to allow the crank to rotate inside the main bearing inner races. I got a local machinist to knurl these surfaces to make them slightly proud, then pressed the mains on with loads of high-strength Loctite bearing fit on the advice of a well-respected MX rider/mechanic but the bottom end lasted about 5 minutes before it happened again.

Also I bought some Athena 56mm top end kit pistons from RRD Preparation (they sell the A, B and C dimension pistons) and they turned up pretty quickly so I'd be happy to order from them again.

WhhoahoooO.C.D!

Seriously though, thanks for the info! I especially liked the lapping the flywheel to the crank. Also the ‘toffee hammer’ That’s showing some age me old nutcracker!

That’s showing some age me old nutcracker!

PS I love info

I thought the bearing slipping was quite common? I kinda hoped it would all ‘true up’ when it came up to temp?...

I want to learn more about balancing the crank as well. I imagine that the tiniest imbalance/imperfection would rob the engine of top end revs, resolution?... -

WhhoahoooO.C.D!

Seriously though, thanks for the info! I especially liked the lapping the flywheel to the crank. Also the ‘toffee hammer’ That’s showing some age me old nutcracker!

That’s showing some age me old nutcracker!

PS I love info

I thought the bearing slipping was quite common? I kinda hoped it would all ‘true up’ when it came up to temp?...

I want to learn more about balancing the crank as well. I imagine that the tiniest imbalance/imperfection would rob the engine of top end revs, resolution?...@SpookDog Thanks man

Forgot to mention, the YouTube vids I watched about lapping the crank/flywheel were all adamant that you should only rotate the flywheel in one direction when you do this.

Forgot to mention, the YouTube vids I watched about lapping the crank/flywheel were all adamant that you should only rotate the flywheel in one direction when you do this.For crank building/truing check out Allen Millyard on YouTube, he builds 5-cylinder Kawasakis by chopping up two sets of 3-cylinder crankcases and welding them together and stuff like that. Tokyo Offroad is a pretty good channel as well, they've done a how-to series on completely rebuilding a KTM TPI engine.

-

@SpookDog Thanks man

Forgot to mention, the YouTube vids I watched about lapping the crank/flywheel were all adamant that you should only rotate the flywheel in one direction when you do this.

Forgot to mention, the YouTube vids I watched about lapping the crank/flywheel were all adamant that you should only rotate the flywheel in one direction when you do this.For crank building/truing check out Allen Millyard on YouTube, he builds 5-cylinder Kawasakis by chopping up two sets of 3-cylinder crankcases and welding them together and stuff like that. Tokyo Offroad is a pretty good channel as well, they've done a how-to series on completely rebuilding a KTM TPI engine.

@HOTSHOT-III

Great info and drawings too !! -

@HOTSHOT-III

Great info and drawings too !!@Scootjockey Thanks bud

That adaptor is the correct size for the DTR main bearings and crankcases but potentially you could have one made for any engine. Mine was done by a local machine shop.

That adaptor is the correct size for the DTR main bearings and crankcases but potentially you could have one made for any engine. Mine was done by a local machine shop.Even when you watch the Rocky Mountain ATVMC how-to vid where the crank puller is branded "Tusk" for the US market they still transmit a side load through the bearing and lots of people have commented on it