What was I thinking!…

-

Seeing as the original tailpipe is busted I decided to use some of it to make another.

I cut the threaded ring off of the bit that was snapped off from the inside of the original.

Then I cut the excess jointing pipe off of the big1 tail pipe.

So I could join it to the big1 tailpipe.

I drilled holes in the big1 to match.

Then used Allen bolts to join them.

The idea being it ‘locks’ the Allen bolts in place and lets me use the joining gasket from the original. So I can remove the big1 tailpipe without having to dismantle it to get to the Allen bolts heads, if/when I want to remove it. I just have to undo 3 10mm nuts.

End product:

@SpookDog Bud, that looks factory! Nice work

-

@SpookDog Bud, that looks factory! Nice work

Cheers guys! I only hope that it works

The big1 is like any other aftermarket one, it has nothing but a pierced hole tube with fibre wadding. I’ve got the carb and air box fitted. I just need to add the loom and a battery to fire it up. Monies are tight though, I’ve gotten my tax & mot & insurance all due this month 🤪 …

The big1 is like any other aftermarket one, it has nothing but a pierced hole tube with fibre wadding. I’ve got the carb and air box fitted. I just need to add the loom and a battery to fire it up. Monies are tight though, I’ve gotten my tax & mot & insurance all due this month 🤪 …I do have the rubber repair kits for the front brake master & calliper to be getting on with.

I’ve stripped the rear calliper without breaking anything, just need to order repair kits for it and the 13mm Brembo master that it uses…Wish me luck, please!…

One step closer…

-

Cheers guys! I only hope that it works

The big1 is like any other aftermarket one, it has nothing but a pierced hole tube with fibre wadding. I’ve got the carb and air box fitted. I just need to add the loom and a battery to fire it up. Monies are tight though, I’ve gotten my tax & mot & insurance all due this month 🤪 …

The big1 is like any other aftermarket one, it has nothing but a pierced hole tube with fibre wadding. I’ve got the carb and air box fitted. I just need to add the loom and a battery to fire it up. Monies are tight though, I’ve gotten my tax & mot & insurance all due this month 🤪 …I do have the rubber repair kits for the front brake master & calliper to be getting on with.

I’ve stripped the rear calliper without breaking anything, just need to order repair kits for it and the 13mm Brembo master that it uses…Wish me luck, please!…

One step closer…

-

Found out that the FZ600R uses the same Sumitomo callipers as mine. There’s a pair of them on fleabay for £65, in excellent condition with pads! I wish it was one of the times that I had monies!!

…

…

I would love to put twin discs on this!…Actually they are similar, not identical!

One thing I really am not keen on is the big fat 250 ass on this bike. It looks kinda stupid with the 150 tyre under it. I want to find a nice slimline single seat pod to fit to it. Any input appreciated…

I’m thinking 1980’s gsxr slab side kinda thing…

-

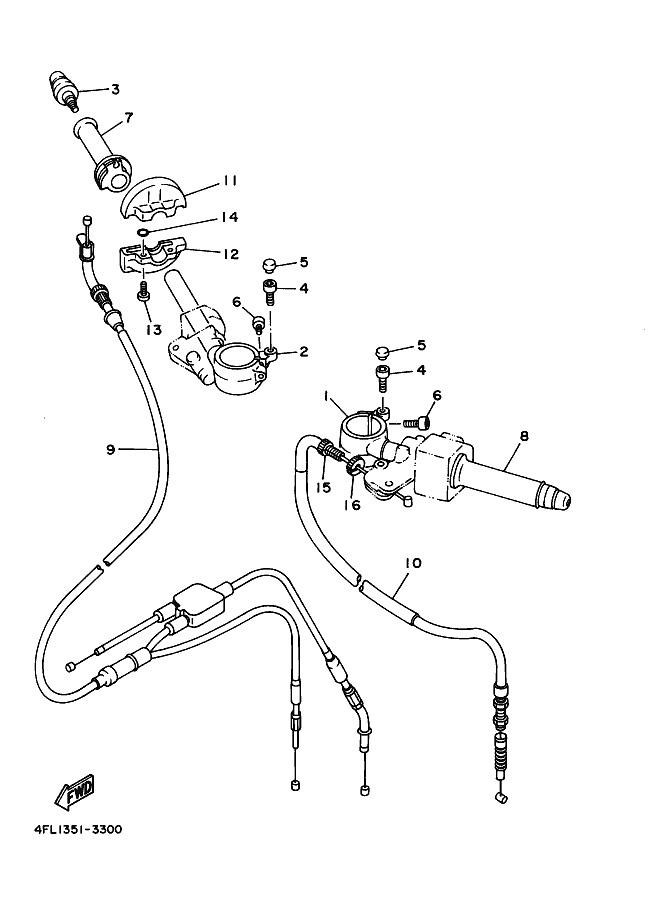

@Calum I thought only 250cc+ Yamahas had the third cable from the YPVS servo to the oil pump, so I looked at the 4FL TZR125R on Yamaha France and sure enough, it's shown as part of the throttle cable!

It's known as a "see-saw linkage" and its purpose is to further increase the oil delivery rate when the YPVS opens and the bike comes on the pipe as this is a high load application when the engine needs a lot of oil. It was fitted to the TDR and TZR250 parallel twins and probably the Reverse Cylinder and V-Twin TZR250s as well.

I was very surprised to see this on a DTR-derived engine, I guess this combined with the strange looking ignition advance curve and plated bore as standard all point to the fact that the TZR125R is meant to rev a lot higher than the 10,500rpm you can expect from a well-sorted stock DTR.

https://dt125r.co.uk/post/30119

Interestingly the original 2RH TZR125 which was released in 1986 was also well-known to rev to around 12,000rpm when derestricted, and whilst they didn't have a plated bore the 2RH cylinder and head did have a weirdly enormous water jacket, I mean they were roughly the same physical size as a Suzuki TS250X top end or something like that. Looking at mates' TZRs as a youth I always thought it looked a bit out of place sat on what were basically DTR crankcases (the TZR125R plated cylinder is outwardly the same as a 3MB DTR cylinder IIRC). I think this was an attempt to achieve the required heat transfer into the coolant for those kinds of engine speeds without the expense of a plated bore as this was fairly new technology in the motorcycle world in the mid 80s.

I must admit I was never a fan of the 2RH engine, I knew a few people who made them quite fast but they had a weaker clutch than the DTR, and also a particularly horrible front sprocket retention using one of those little locking plates and two M6 bolts like a C90 step-thru meaning if you buy a 2RH TZR125 to restore today, you can pretty much guarantee a knackered output shaft. And very low compression for some reason, whenever someone let me have go on one I thought it had blown up just kicking it over. Yamaha made some intelligent mods to make it strong enough for DTR use.

Re: the see saw linkage. I read somewhere that it’s for during overrun, when the revs are above 6-7k but the throttle is closed. It kinda makes sense as it’s activated by the power valve servo? What you recon?…

-

Re: the see saw linkage. I read somewhere that it’s for during overrun, when the revs are above 6-7k but the throttle is closed. It kinda makes sense as it’s activated by the power valve servo? What you recon?…

-

Re: the see saw linkage. I read somewhere that it’s for during overrun, when the revs are above 6-7k but the throttle is closed. It kinda makes sense as it’s activated by the power valve servo? What you recon?…

@SpookDog Yes I think that's one of the aims of having the see-saw linkage, to avoid the motocrosser-seizing-at-the-end-of-the-main-straight-at-a-beach-race scenario. I guess the TZR125R in its natural habitat could benefit more from this than a DTR because if you took it on a track day somewhere, you'd spend a fair bit of time per lap braking for corners whilst keeping the revs up to get on the power mid-corner and on the exit.

From memory I think the RGV250 had a similar system but don't quote me on this. The fact the TZR250 parallel twin had this and the 350YPVS didn't is IMO a factor in the TZR250 being able to reliably do everything the 350 'valve could do with 100cc less.

-

Bud! What does your re max out at when riding? RPM’s I mean. I know yours is tuned but I’m trying to find out what the Athena 170 revs out to…

-

@SpookDog said in What was I thinking!…:

If anyone can tell me what the 170 Athena revs out to, please do!

If memory serves well,I saw about 13000 rpm/5th gear,136km/h on the road when it was running good last time,run out of road for the 6th gear.

-

@SpookDog My 3MB ran very well on this stuff, equal spec (JASO FD is the Japanese industry standard for racing two-stroke oil) to all the brand-named oils and I've known MX/Enduro guys to run it in modern KTMs etc with no issues:

Very good ebay seller generally, they have similar deals on grease and stuff

-

@SpookDog My 3MB ran very well on this stuff, equal spec (JASO FD is the Japanese industry standard for racing two-stroke oil) to all the brand-named oils and I've known MX/Enduro guys to run it in modern KTMs etc with no issues:

Very good ebay seller generally, they have similar deals on grease and stuff

Cheers bud, looks good. Any issues with sticky power valves? I bought some cheap synthetic 2T that was fine except for it making the power valve gum/stick-y

-

Cheers bud, looks good. Any issues with sticky power valves? I bought some cheap synthetic 2T that was fine except for it making the power valve gum/stick-y

@SpookDog I always found Exol very clean burning. Interestingly it's exactly the same shade of pinky red as Motorex Cross Power 2T which is nearly 4 times the price.

Are you still being cautious about revving your bike too high? It's a wise precaution but also you need to balance this with the fact two-strokes need to be revved to keep clean and a lot of carbon-seized powervalve issues are caused by spending a lot of runtime at low rpm, Enduro bikes threading a needle through the trees are more susceptible than the equivalent MX bike being thrown round a track by the local hotshoe for example. Always a good idea to give it a good thrash through the gears a couple of times every ride and blow the carbon out

-

I use Castrol power 1 race, fully synthetic can get it from halfords.

I always get mine up to temp for a few miles then always at 10k rpm most of the time in each gears, always gets a beating when it comes out and never had an issue with anything sticking

-

I do stick to around 5K with 6 being my limit. This is because of the state of the engine though! Not for any altruistic reason!

it’s rough! The last 2 pistons had the ‘ring pins’ rattled out of them. The stator side of the piston had about a MM of play in the wrist/gudgeon pin! I think the con rod is bent to one side. The barrel I put on it I used the only piston that was a close fit, it was one that has been seized twice and has a crater in the crown from overheating. So I’m nursing it till my next rebuild, I consider it to be in ‘lump mode’

it’s rough! The last 2 pistons had the ‘ring pins’ rattled out of them. The stator side of the piston had about a MM of play in the wrist/gudgeon pin! I think the con rod is bent to one side. The barrel I put on it I used the only piston that was a close fit, it was one that has been seized twice and has a crater in the crown from overheating. So I’m nursing it till my next rebuild, I consider it to be in ‘lump mode’  It’s been so reliable considering it’s ‘pedigree’ …

It’s been so reliable considering it’s ‘pedigree’ … -

I do stick to around 5K with 6 being my limit. This is because of the state of the engine though! Not for any altruistic reason!

it’s rough! The last 2 pistons had the ‘ring pins’ rattled out of them. The stator side of the piston had about a MM of play in the wrist/gudgeon pin! I think the con rod is bent to one side. The barrel I put on it I used the only piston that was a close fit, it was one that has been seized twice and has a crater in the crown from overheating. So I’m nursing it till my next rebuild, I consider it to be in ‘lump mode’

it’s rough! The last 2 pistons had the ‘ring pins’ rattled out of them. The stator side of the piston had about a MM of play in the wrist/gudgeon pin! I think the con rod is bent to one side. The barrel I put on it I used the only piston that was a close fit, it was one that has been seized twice and has a crater in the crown from overheating. So I’m nursing it till my next rebuild, I consider it to be in ‘lump mode’  It’s been so reliable considering it’s ‘pedigree’ …

It’s been so reliable considering it’s ‘pedigree’ …@SpookDog Understandable you're keeping the revs low in the circumstances but I'd say that's a big part of the PV being carbon seized.

Also I think your running premix is playing a part here. Besides user convenience, one of the greatest attributes of Autolube is its flexibility as the oil delivery rate is varied in two ways; engine speed and throttle opening (or three if you count the TZR-R see-saw linkage but I'm assuming we're talking about your DTR here) so it really is a mechanical form of engine management which varies the oil ratio from about 120:1 at tickover to something like 30:1 when you're absolutely full bore giving it the beans.

Premix is fine for competition bikes as it's assumed you'll be ragging the arse off it for most of the time you're riding, but road bikes have to spend time in everyday traffic situations where that kind of riding just isn't possible so you don't really need that 40:1 or whatever oil ratio sat in traffic at 4000rpm. So it oils everything up because it's not being blown out like it would be on a track. In fact it could be having a negative effect because if there's a percentage of oil as well as petrol going through any carb jet at any engine speed/throttle opening, this could translate to a lean running/overheating condition.

If you're planning on doing a full engine rebuild sometime, get a £25 Yambits oil pump repair kit and if you have a spare, do a clutch cover build with the oil pump fitted so it's ready. They also do a ball and spring kit for the outlet pipe and a transparent delivery pipe kit so you can check at a glance it's working, and after rebuilding you can pre-bleed the pump using a syringe so the final bleed on the bike is easier. The DTR Autolube is even better than most as the OEM throttle cable actually has a mechanism inside the splitter box which balances the carb and oil pump automatically (another reason to avoid those bloody awful £12 pattern throttle cables which are responsible for a lot of engine meltdowns) whereas even all other Yamahas you have to check and adjust the oil pump cable regularly. And Suzukis right up to the RGV250, the oil pump is a weedy little thing behind the front sprocket. Yamaha Autolube is one of the most reliable and user-friendly systems ever made and seeing this gives you rock-solid peace of mind.

In the 90s an American tuner called Eric Gorr wrote an article in Dirt Bike Rider (UK) Magazine about cleaning up gummy powervalves as some of them are quite complicated (the Honda Power Port valves on the '86-91 Honda CR250 had over 20 moving parts and required servicing every two hours' runtime, but the CR was the best 250MX engine of its era). He talked a lot about this, Kawasaki KIPS, Suzuki AETC etc, all of which are equally fiddly but he left out Yamaha YPVS altogether because in his own words "the Yamaha system is so simple and reliable".

-

@SpookDog Understandable you're keeping the revs low in the circumstances but I'd say that's a big part of the PV being carbon seized.

Also I think your running premix is playing a part here. Besides user convenience, one of the greatest attributes of Autolube is its flexibility as the oil delivery rate is varied in two ways; engine speed and throttle opening (or three if you count the TZR-R see-saw linkage but I'm assuming we're talking about your DTR here) so it really is a mechanical form of engine management which varies the oil ratio from about 120:1 at tickover to something like 30:1 when you're absolutely full bore giving it the beans.

Premix is fine for competition bikes as it's assumed you'll be ragging the arse off it for most of the time you're riding, but road bikes have to spend time in everyday traffic situations where that kind of riding just isn't possible so you don't really need that 40:1 or whatever oil ratio sat in traffic at 4000rpm. So it oils everything up because it's not being blown out like it would be on a track. In fact it could be having a negative effect because if there's a percentage of oil as well as petrol going through any carb jet at any engine speed/throttle opening, this could translate to a lean running/overheating condition.

If you're planning on doing a full engine rebuild sometime, get a £25 Yambits oil pump repair kit and if you have a spare, do a clutch cover build with the oil pump fitted so it's ready. They also do a ball and spring kit for the outlet pipe and a transparent delivery pipe kit so you can check at a glance it's working, and after rebuilding you can pre-bleed the pump using a syringe so the final bleed on the bike is easier. The DTR Autolube is even better than most as the OEM throttle cable actually has a mechanism inside the splitter box which balances the carb and oil pump automatically (another reason to avoid those bloody awful £12 pattern throttle cables which are responsible for a lot of engine meltdowns) whereas even all other Yamahas you have to check and adjust the oil pump cable regularly. And Suzukis right up to the RGV250, the oil pump is a weedy little thing behind the front sprocket. Yamaha Autolube is one of the most reliable and user-friendly systems ever made and seeing this gives you rock-solid peace of mind.

In the 90s an American tuner called Eric Gorr wrote an article in Dirt Bike Rider (UK) Magazine about cleaning up gummy powervalves as some of them are quite complicated (the Honda Power Port valves on the '86-91 Honda CR250 had over 20 moving parts and required servicing every two hours' runtime, but the CR was the best 250MX engine of its era). He talked a lot about this, Kawasaki KIPS, Suzuki AETC etc, all of which are equally fiddly but he left out Yamaha YPVS altogether because in his own words "the Yamaha system is so simple and reliable".

Hey bud! I stripped and cleaned the PV when it last got gummed up. It wasn’t carbon. It happens within 2-3 days of using the ‘emergency’ 2T oil. I think that all the misfiring (20,000miles!!) has done a number on the conrod, I’m surprised the bearings are still good! I had the piston’lock’ a couple times when the head gasket was really bad & I was topping up the rad every 10 miles. I had to put it in a high gear and rock it back and forwards till it cleared!…

I plan on putting the pump back on when I rebuild the Dtr. I can’t remember why I went premix exactly, it was to cross something off a list though. I think premix can be problematic with setting up the carb…

I’m going to read through your whole post now! …

…Edit: I would not want to service that power valve setup!! Damn! 🫣

PPS: I have a pic of the worn piston - pin clearance on the stator side, I’ll try and find it. You’ll understand why I’m in limp mode

…

… -

Hey bud! I stripped and cleaned the PV when it last got gummed up. It wasn’t carbon. It happens within 2-3 days of using the ‘emergency’ 2T oil. I think that all the misfiring (20,000miles!!) has done a number on the conrod, I’m surprised the bearings are still good! I had the piston’lock’ a couple times when the head gasket was really bad & I was topping up the rad every 10 miles. I had to put it in a high gear and rock it back and forwards till it cleared!…

I plan on putting the pump back on when I rebuild the Dtr. I can’t remember why I went premix exactly, it was to cross something off a list though. I think premix can be problematic with setting up the carb…

I’m going to read through your whole post now! …

…Edit: I would not want to service that power valve setup!! Damn! 🫣

PPS: I have a pic of the worn piston - pin clearance on the stator side, I’ll try and find it. You’ll understand why I’m in limp mode

…

… -

I wish I could afford to take bigger steps. Sucks working outside this time of year with the weather changing all the time, it gets dark!…