Dt 125 r,re,e?

-

Hi all new here looking for some help with my dt its got a 3bn00 head 3bn02 bottom end is the 00 02 the year?

Frame is a 89 dt125e but been told the engines a dtr?

Aside from that the swingarm bolt is stuck to the spacer/bush on the sprocket side of the case cant for the life of me get it out short of turning the spacer to liquid.

Engine needs full seal kit water pump impeller gear shaft piston and small end bearing

Going to do some porting to the head nothing too major,

Frames got 3 layers of paint on it so if anyone can recomend good paint stripper that would be great as i want to spray it blue,

Want to eventually put better forks shock wheels and tyres on it thanks for reading have a good day

3bn 02 (or 01or 03) is just what gets stamped into every casing IIRC. I don’t know what it refers to, some minor change that doesn’t really affect anything probably

…

…Look for your proper engine number above and behind the front sprocket. There will be a number and then a couple letters.

3BN

3MB

4DL

Ect…This will give an indicator of the engines year. It’s usually the same as the frame number…

When you say the bolt is stuck, you’ve removed the nut from the other side already?

Yes no?If it’s the bolt: is it turning? Just not pulling out? Need more info

…

… -

3bn 02 (or 01or 03) is just what gets stamped into every casing IIRC. I don’t know what it refers to, some minor change that doesn’t really affect anything probably

…

…Look for your proper engine number above and behind the front sprocket. There will be a number and then a couple letters.

3BN

3MB

4DL

Ect…This will give an indicator of the engines year. It’s usually the same as the frame number…

When you say the bolt is stuck, you’ve removed the nut from the other side already?

Yes no?If it’s the bolt: is it turning? Just not pulling out? Need more info

…

…@SpookDog above the sprocket at the usual marking spot for the engine numbers there is nothing havent checked behind it

A got the nut off the swingarm bolt and have let the bolt sit for a week with wd40 on it and have got the bolt turning freely but it wont go through because its stuck on the spacer in between the swingarm and the casing on the sprocket side of the engine swingarm and engine move up and down freely its just the spacer thats stuck on the bolt -

@SpookDog above the sprocket at the usual marking spot for the engine numbers there is nothing havent checked behind it

A got the nut off the swingarm bolt and have let the bolt sit for a week with wd40 on it and have got the bolt turning freely but it wont go through because its stuck on the spacer in between the swingarm and the casing on the sprocket side of the engine swingarm and engine move up and down freely its just the spacer thats stuck on the boltThere shouldn’t be any spacer. Just cap/seals on the outside of the swingarm. There is a metal bush/tube inside the swingarm that has probably rusted to the bolt. Or the centre section that lives inside the engine has rusted and won’t pass through the swingarm bush. Either way you’re going to have to drift it out with a big old hammer. That or cut the hex head off and try and beat it through the other way…

Never a good thing when a previous owner has ground off engine numbers

…

… -

There shouldn’t be any spacer. Just cap/seals on the outside of the swingarm. There is a metal bush/tube inside the swingarm that has probably rusted to the bolt. Or the centre section that lives inside the engine has rusted and won’t pass through the swingarm bush. Either way you’re going to have to drift it out with a big old hammer. That or cut the hex head off and try and beat it through the other way…

Never a good thing when a previous owner has ground off engine numbers

…

…@SpookDog Yes he probably means the spindle is rusted to the sleeve which fits inside the swingarm bearing on the drive side. Jim Bailey sells replacement swingarm spindles for the DTR if it has to be chopped up to remove it.

@crm2090 You might be able to save the original swingarm spindle by adapting this method with a longer length of M6 studding:

-

@SpookDog Yes he probably means the spindle is rusted to the sleeve which fits inside the swingarm bearing on the drive side. Jim Bailey sells replacement swingarm spindles for the DTR if it has to be chopped up to remove it.

@crm2090 You might be able to save the original swingarm spindle by adapting this method with a longer length of M6 studding:

@HOTSHOT-III i tried that method of removing the bolt with no luck i was snapping 8mm threaded rods because of the tension created when i tried to turn the nut got any other suggestions?

-

@HOTSHOT-III i tried that method of removing the bolt with no luck i was snapping 8mm threaded rods because of the tension created when i tried to turn the nut got any other suggestions?

-

@HOTSHOT-III i tried that method of removing the bolt with no luck i was snapping 8mm threaded rods because of the tension created when i tried to turn the nut got any other suggestions?

@crm2090 This situation needs very careful handling; I've known people to have to re-frame their DTR due to the swingarm spindle being this badly seized. And finding a decent DTR frame with numbers/V5 isn't easy these days (£500+).

On the other hand a usable swingarm can be had for around £50 so I think I'd be moving towards chopping that up to get to the spindle and whatever it's rusted to (hopefully one of the bearing sleeves).

If you take out the shock and linkage and take off the airbox/rear mudguard you'll have a surprising amount of space to impersonate the rear wheel, then you can chop off the swingarm as close as possible to the pivot to give you room to then get to work cutting out sections of the pivot/spindle area to hopefully free it. And I think you will end up having to drill out the hex head like @SpookDog said.

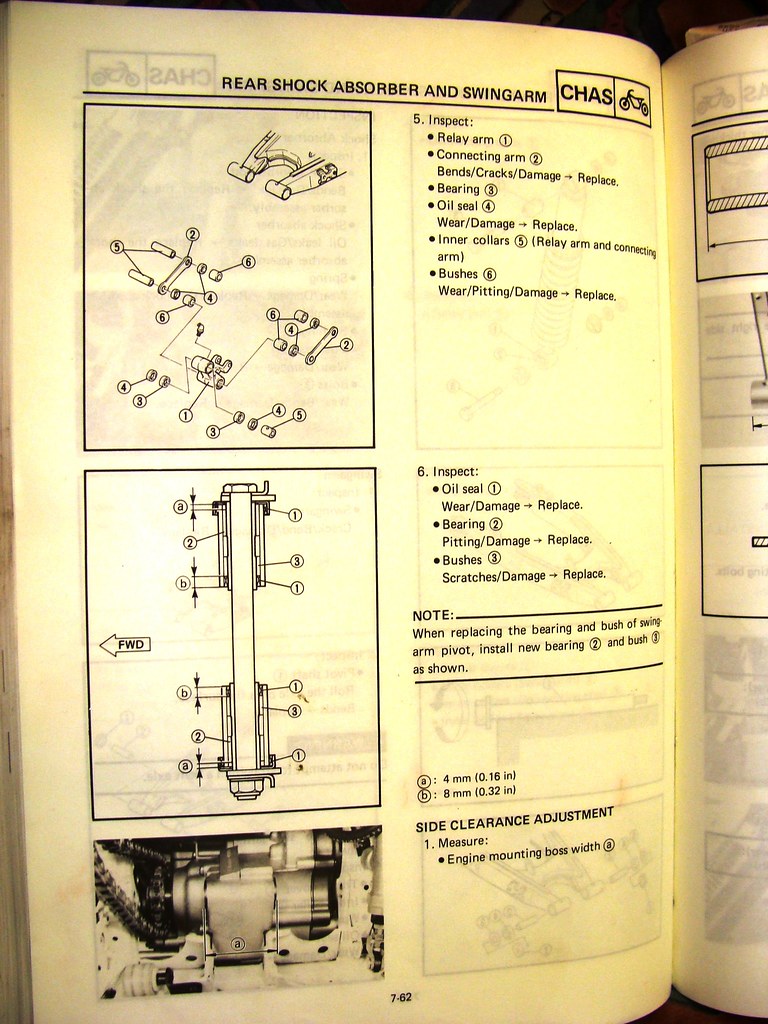

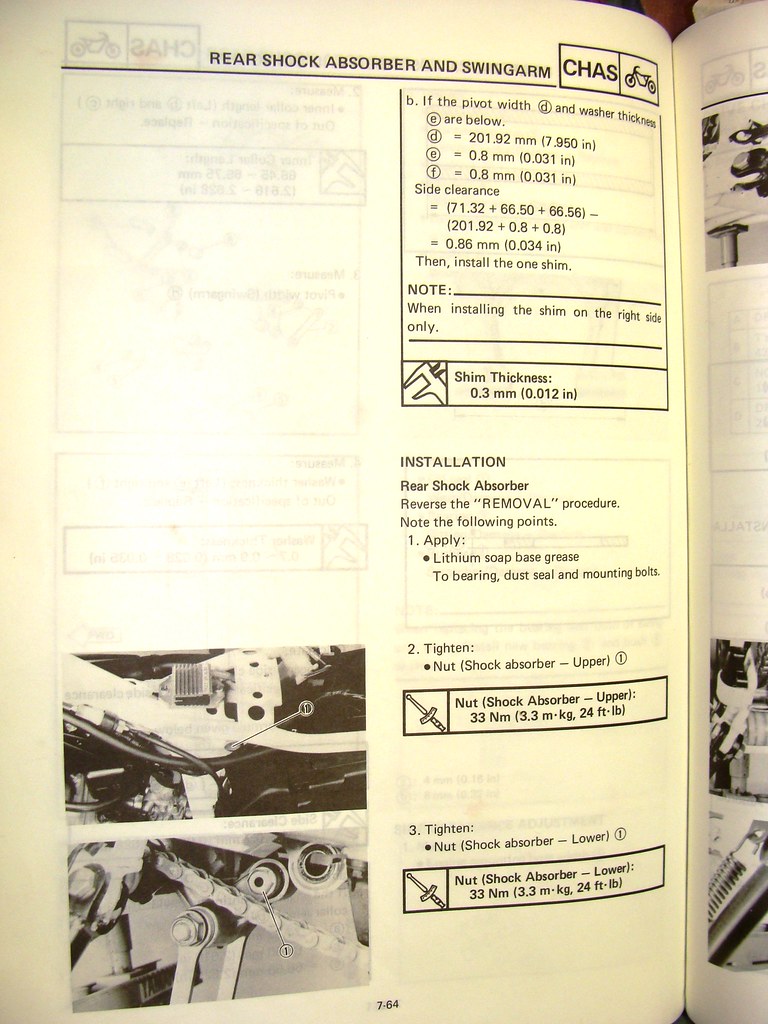

What is really important here is to avoid doing any damage to the engine boss at the back of the crankcases as this is a specific width to enable setting of the swingarm side clearance once you've got a new swingarm. This is a very important step when refitting the arm as it ensures perfect sprocket alignment; done right you can get the arm to fall under it's own weight with under 0.5mm side-to-side play for cushion-of-air suspension action and excellent chain and sprocket life.

Here are some pics from the Yamaha service manual showing the procedure. They make it look/sound more complicated than it really is, a lot of people skip this step and then report uneven sprocket wear afterwards and even some of the "specialist DTR restorers" don't bother with it.

So I guess it comes down to the best way to cut through what's left of the arm to remove it without damaging the engine boss (or the frame, although of the two, it's the engine boss which ultimately dictates the position of the arm as you can see in the last pic, a bench mock-up I did with a DT200R 3ET alloy arm and wheel spacers and 125 crankcases and hub). Angle grinder (or one of those cordless mini angle grinders) if you're careful, or maybe one of those oscillating cutter things plumbers use to remove pipes from tight spaces?

If anyone on here has been in this situation and survived it would be great to hear how they did it!

-

@HOTSHOT-III i tried that method of removing the bolt with no luck i was snapping 8mm threaded rods because of the tension created when i tried to turn the nut got any other suggestions?

Did you try leaving it under tension? Then heating the swing arm ‘knuckles’ either side? The chances are it’s going to be the bushes inside seized to the bolt. Either that or the bolt ballon’s with rust in the centre were it passes through the engine, thought that would allow some small movement…

Hotshot is spot on. A good solid frame is unicorn shit nowadays. You can get cases (with numbers

) and swingarms all the time…

) and swingarms all the time…