So Close!...

-

I couldn’t find a single new bush! Cheers bud! Is there a fleabay listing that sell them specifically? I need to get a proper vernier calliper to measure things. I can’t find a half decent one of those. Just Chinese things! I don’t seem to be having any luck searching from my iPhone…

@SpookDog Those Chinese digital verniers are ace, I bought one for £5 in 2011 and I'm still using it. Exactly the same thing is around £40 in Machine Mart but Aldi/Lidl sell them cheap every now and then.

Bushes I'm not sure, I've never known a PV bush to be worn enough to replace but I guess you could take the parts to a bearing shop and get them to measure up and order you some.

Is there any way you could get access to a PC? Smartphones are excellent for what they are but it's difficult looking around for the best deal on a screen the size of a fag packet. Even if you just go online down the Library you can have 3 or 4 windows open on a big screen, makes comparing suppliers etc. a lot easier.

-

@SpookDog Those Chinese digital verniers are ace, I bought one for £5 in 2011 and I'm still using it. Exactly the same thing is around £40 in Machine Mart but Aldi/Lidl sell them cheap every now and then.

Bushes I'm not sure, I've never known a PV bush to be worn enough to replace but I guess you could take the parts to a bearing shop and get them to measure up and order you some.

Is there any way you could get access to a PC? Smartphones are excellent for what they are but it's difficult looking around for the best deal on a screen the size of a fag packet. Even if you just go online down the Library you can have 3 or 4 windows open on a big screen, makes comparing suppliers etc. a lot easier.

I’ve got an old servo side bush that is light years better. The old one you could literally rattle the power valve!! I’ve got a 4fu (male bush) for the other side that is better as well. That side wasn’t as worn though. I’m going to try them, as well as doubling up the base gasket…

Wish me luck! I’m hopeful cause I sure as shit can’t think what else could be giving me the same symptoms…

PS! I finally got the Blaster 200 small end bearing fitted! I went the other way and took a bit off of each side of the bearing. Easier to do and cheaper if I’d fuxed it up! Easier to de-swarf as well

…

… -

Now I’ve got a decision to make. What extra gasket to apply to the base of the barrel. I’ve got a standard thickness of 1mm and a 0.5mm.

Do I go to 1.5 or 2? I’m leaning towards 2mm to be safe, rather a little too much than not enough. I can at least knock it off the list then…@SpookDog said in So Close!...:

Now I’ve got a decision to make. What extra gasket to apply to the base of the barrel. I’ve got a standard thickness of 1mm and a 0.5mm.

Do I go to 1.5 or 2? I’m leaning towards 2mm to be safe, rather a little too much than not enough. I can at least knock it off the list then…Why you want to do that?

If you go with 1mm at the base you can use an 0.5mm on the head,will give you 1.1 squish if I remember correctly.

I made 1.1mm (2x0.55mm) at the base and with 0.55mm at the head the piston came flat with the cylinder and gave me an 1.2mm squish,all copper and handmade.

-

@OllieDTR said in So Close!...:

My squish is 0.8mm tight but it’s fast lol

You are on 125cc which is ok,for 170cc such a squish is on the red zone for piston hitting.

Graham Bell has a pic for the given cc how much must be the squish.Like I said, I had to lap the mouth of the crankcase level. I did it after fitting the head gasket so I couldn’t check the level of the piston crown to the top of the barrel.

I’m trying to get it running properly. I’m not in a position to even be thinking about tuning the squish band…—————————

Just putting it together again. Power valve feels proper again, not rattling around! Remembered to fit the banjo unions as well

It spends far too much time like this. Hopefully it’s fixed now…

-

Like I said, I had to lap the mouth of the crankcase level. I did it after fitting the head gasket so I couldn’t check the level of the piston crown to the top of the barrel.

I’m trying to get it running properly. I’m not in a position to even be thinking about tuning the squish band…—————————

Just putting it together again. Power valve feels proper again, not rattling around! Remembered to fit the banjo unions as well

It spends far too much time like this. Hopefully it’s fixed now…

FFS! I can’t believe it but the base gasket is leaking from the same spot as before!

I think there must be a slight V at the top of where they join. I put an extra dot of sealant there last time (that it didn’t leak!)

I’m going to use silicon RTV the next time. I should of used it to seal the crankcase halves, but I used tube type ‘hermatite’ and I think I ‘washed it out’ while lapping…I’m going to test ride it tomorrow after plugging the leak temporarily. See if at least I fixed the running problem at 1/8 throttle…

Can’t seem to catch any breaks! Always fuxin something with me!

-

I lapped the high side down to match the low. Then the whole thing flush. Using plate glass, wet & dry & wd40. It was only a hairs width…

You can see the problem, where the two cases join? The gasket is only 5mm wide at that point. There’s a definite gap where I’ve ‘washed out’ the sealant between the two cases. I just need to be super careful with that spot…

-

I lapped the high side down to match the low. Then the whole thing flush. Using plate glass, wet & dry & wd40. It was only a hairs width…

You can see the problem, where the two cases join? The gasket is only 5mm wide at that point. There’s a definite gap where I’ve ‘washed out’ the sealant between the two cases. I just need to be super careful with that spot…

-

Cheers buddy! I’ve been labouring under a misconception!

I’m planning on using copper RTV silicon with a new gasket. 700deg stuff. I’ve had good results with it before. There’s quite an open groove at the front where the two cases join…I’ll be using it when I next put two cases together as well!

…

… -

@SpookDog If you speak for the base gasket then I advise you to go for a copper one with the Permatex Copper Spray gasket I had mentioned you in some older post here.

Yamaha's base gasket is metallic with black coating and with some melting stuff that forms a line around to seal better. -

@SpookDog If you speak for the base gasket then I advise you to go for a copper one with the Permatex Copper Spray gasket I had mentioned you in some older post here.

Yamaha's base gasket is metallic with black coating and with some melting stuff that forms a line around to seal better. -

Initial test ride is promising. Cruising at 25-30 without the previous issues. No tap-rattle and humming from the top end! Won’t know for sure till I take it on a 20-30 mile run though…

Put a spot of chemical metal over the leak for temporary/now…

-

Initial test ride is promising. Cruising at 25-30 without the previous issues. No tap-rattle and humming from the top end! Won’t know for sure till I take it on a 20-30 mile run though…

Put a spot of chemical metal over the leak for temporary/now…

Just noticed something potentially interesting. The red 2T oil warning light flickers at just about 4K rpm, at the same time I get a little ‘snaggle’ in the revs. Feels a bit like when you rev the engine when it’s cold. Just hesitating slightly. I’d of thought that when the flywheel is spinning at that speed the electrical output would be constant, whether the engine is firing or not? So it’s be something that interrupts the ignition and oil light simultaneously. No?…

Where is the diode located?…

-

Just noticed something potentially interesting. The red 2T oil warning light flickers at just about 4K rpm, at the same time I get a little ‘snaggle’ in the revs. Feels a bit like when you rev the engine when it’s cold. Just hesitating slightly. I’d of thought that when the flywheel is spinning at that speed the electrical output would be constant, whether the engine is firing or not? So it’s be something that interrupts the ignition and oil light simultaneously. No?…

Where is the diode located?…

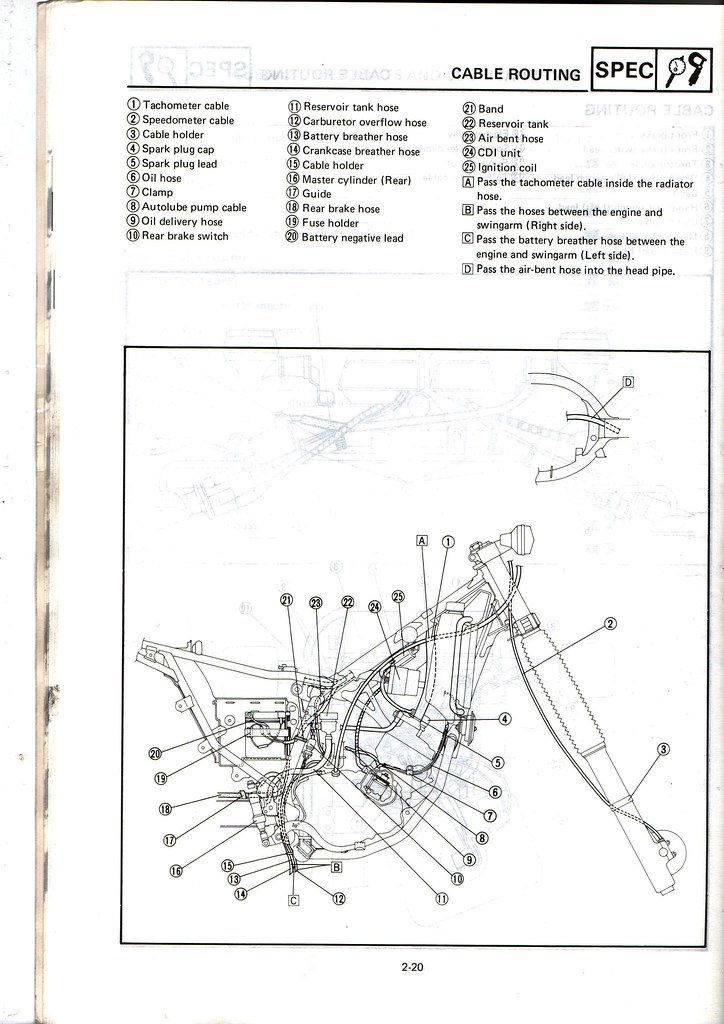

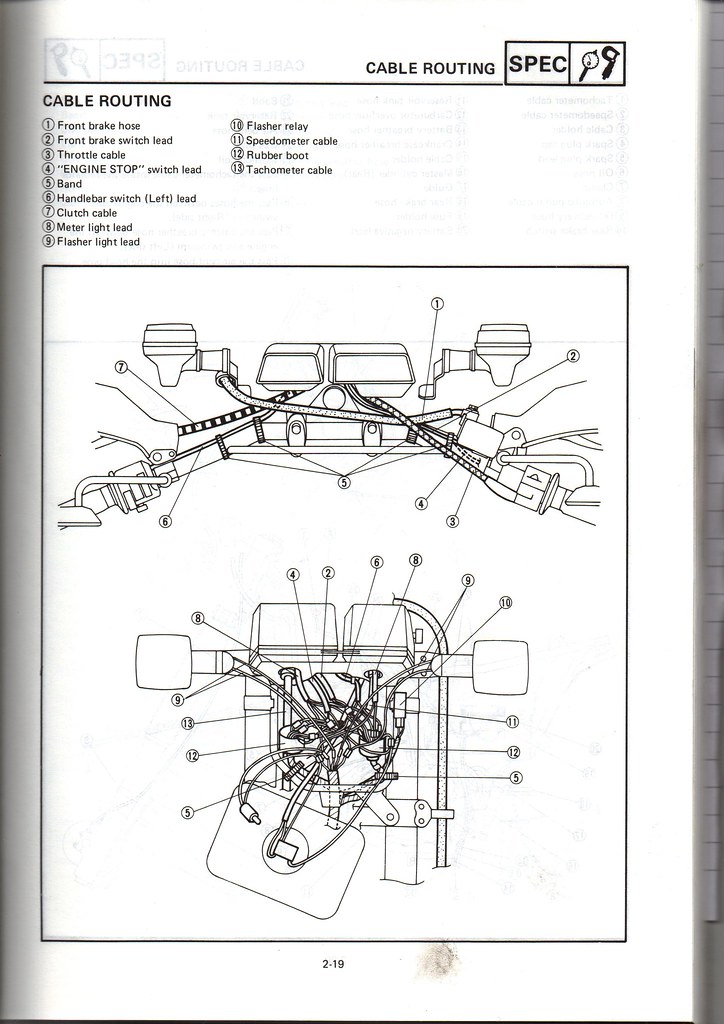

@SpookDog The diode is shown on all wiring diagrams as connecting the black/red oil light wire to the sky blue neutral light wire between the oil level sender unit and the 3-pin connector, i.e on the sub-loom for the sender unit. The oil light bulb wires are brown (main feed from the switch) and black/red (which goes to earth either when the sender unit operates from low 2T oil or via the neutral switch through the diode) so ordinarily it illuminates via either of these things happening.

Are you certain the neutral light isn't flickering at the same time? If it definitely isn't, you can rule out the sky blue wire tracking to earth (and therefore the diode) which means it must be the black/red wire doing this somewhere. Someone mentioned your ignition coil is fitted the wrong way round in an earlier post, and this area around the servo/coil/throttle cable is a right rat's nest of wiring on all DTRs (including the oil level sender wire) so maybe try swapping this round (i.e so the HT lead is at the bottom and the LT orange wire is at the top). IIRC only one of the mounts on the stock coil is actually an earth, this is the lower one when the coil is fitted correctly so this is where the earth terminal from the loom should attach (and did you remember to scrape the paint off the lower coil mount for a really good main earth? Lots of people fall down this hole when respraying a frame).

This is all I can think of but it's too much of a coincidence if the HT lead is routed differently potentially being forced against the loom with the fuel tank fitted.

I once had a misfire on a VW Golf, my £35 eBay code reader indicated a bad crank sensor so I bought one and fitted it which cured the problem. It was quite difficult to get to so I didn't actually look at the sensor until I got underneath the car to fit the new one, and where the wires passed between the engine block and oil filter housing the insulation had worn through from vibration. Before doing the job, the car always started and ran well apart from a misfire which always occurred at the same engine speed so I think the signal from the crank sensor was just tracking to earth and confusing the ECU.

-

Just noticed something potentially interesting. The red 2T oil warning light flickers at just about 4K rpm, at the same time I get a little ‘snaggle’ in the revs. Feels a bit like when you rev the engine when it’s cold. Just hesitating slightly. I’d of thought that when the flywheel is spinning at that speed the electrical output would be constant, whether the engine is firing or not? So it’s be something that interrupts the ignition and oil light simultaneously. No?…

Where is the diode located?…

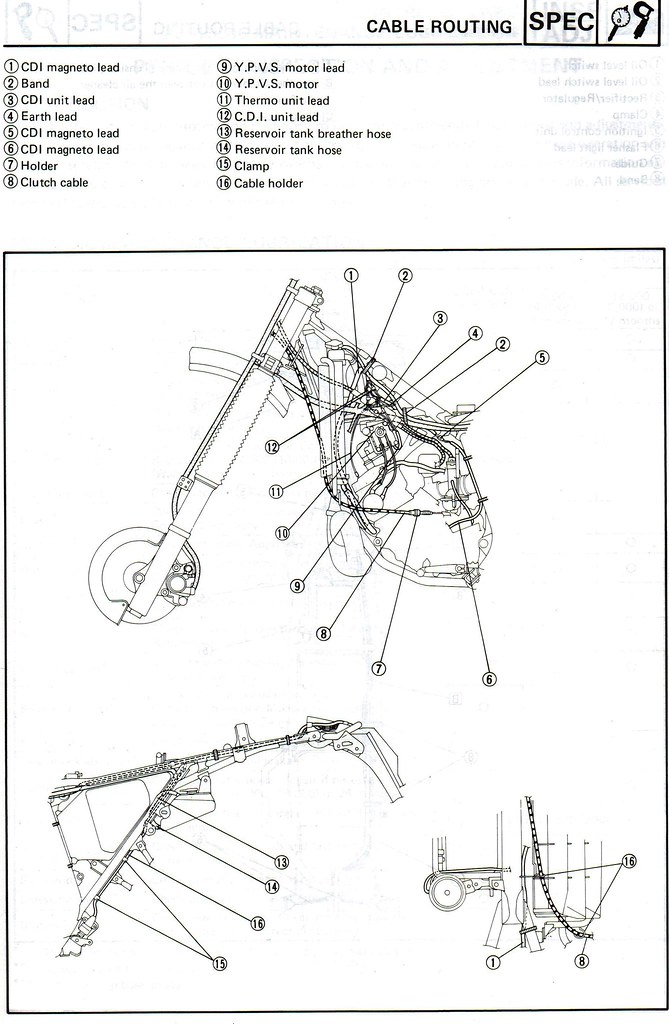

@SpookDog Just been chewing this over a bit more and the orange wire from the CDI energises the low-tension side of the coil (which then goes to earth). Your wiring loom is also on the opposite side of the frame to where it should be which means the CDI wires and the main loom are being forced together, potentially allowing the pulse from the CDI to track to the oil light wire at certain engine speeds (30-year-old wiring and all that). So I'd definitely be having a good poke around in this general area, and looking again at the cable routing images I posted up on here a few weeks ago.

TBH although I understand wiring diagrams, due to my liking for keeping cable routing stock and well coated with WD40 I don't have a huge amount of experience at actually solving electrical problems but if your wiring is incorrectly routed I'd definitely be starting here.