Seized Engine

-

@GiannisT What @Calum said, also if your bike is an early DTR (i.e pre-'99) with the original Autolube pump, Yambits sell a rebuild kit for this which would be preferable to getting a used oil pump. You can still get the shims from Fowlers to adjust the flow rate/stroke (I think it the Yamaha or Haynes manual has a figure). Also early bikes have a mechanism inside the throttle cable splitter box which automatically balances the carb and oil pump at all throttle openings; the OEM cable is expensive but those 12 quid pattern throttle cables are responsible for a lot of DTR engine meltdowns. Get a cable oiler if you do a Yambits order (£5) and lube with Comma Spray Grease.

@HOTSHOT-III ok first of, thanks for the help. My bike is a 93 model (or 96 i always get confused) so i think i will go about repairing the pump as you suggested. Im not based in the UK so ive no clue what fowlers is but from what i saw yambits provides all the shims i would need.

Now on to that throttle cable splitter box mechanism thingy...please help me understand what is and what needs to be done. Im new to the platform and got me bare confused since ive no idea what youre talking about. also if there are parts that i should opt for or definitely avoid i would appreciate some suggestions. -

@GiannisT

Hey bud! Wicked bike to learn mechanics on…

What year is it? Also where are you based?…There’s no reason an engine should seize up ticking over at the lights. It’s more likely a ‘forgot to insert oil’ situation. Especially if it’s still locked up tight (is it still locked up?) Heat seizures usually free off after the engine has cooled down a bit. If this is the case I’d check the crank bearings are running smooth without any rumble/grumbling…

@SpookDog hello mate, the bike is either a 93 or a 96 dtr and I find myself based is Greece. I dont know how the bike locked up or how bad the damage really is since i havent dove into it yet; im going off what my friend told me. The bike has had a fair amount of time to cool down (in fact it has sat for about a year) and I fear greatly finding coolant into my cylinder and having to tear the whole thing apart to deal with that rusty mess. im being hopeful for the moment and trying to figure out how i would deal with the best case scenario. As soon i get into it (should be during the weekend) i ll be running back here asking for additional help.

-

@SpookDog hello mate, the bike is either a 93 or a 96 dtr and I find myself based is Greece. I dont know how the bike locked up or how bad the damage really is since i havent dove into it yet; im going off what my friend told me. The bike has had a fair amount of time to cool down (in fact it has sat for about a year) and I fear greatly finding coolant into my cylinder and having to tear the whole thing apart to deal with that rusty mess. im being hopeful for the moment and trying to figure out how i would deal with the best case scenario. As soon i get into it (should be during the weekend) i ll be running back here asking for additional help.

-

@HOTSHOT-III ok first of, thanks for the help. My bike is a 93 model (or 96 i always get confused) so i think i will go about repairing the pump as you suggested. Im not based in the UK so ive no clue what fowlers is but from what i saw yambits provides all the shims i would need.

Now on to that throttle cable splitter box mechanism thingy...please help me understand what is and what needs to be done. Im new to the platform and got me bare confused since ive no idea what youre talking about. also if there are parts that i should opt for or definitely avoid i would appreciate some suggestions.@GiannisT No worries bud. Fowlers is a big dealership in the UK where a lot of people order their Yamaha parts from but if you're in Europe, CMSNL and Yamaha Amsterdam are also very good:

https://www.yamahacenteramsterdam.nl/en/

And Yamaha France parts lookup is the most accurate I've ever used, you can input your VIN number and it should find your bike:

https://www.yamaha-motor.eu/fr/fr/service-support/parts-catalogue/

The throttle cable splitter box is really simple, if you buy a genuine Yamaha cable by part number it comes assembled and complete and the balance mechanism is inside the box halfway down the cable where the two cables go to the carb and oil pump. You don't have to do anything to it apart from lubing it like any other cable, like I say it automatically balances the carb and oil pump at all throttle openings which is why genuine throttle cables for early bikes like yours don't have an adjuster on the oil pump cable. The TZR125 never had this, it was only the DTR as far as I know. Here's an explanation and pic from the Haynes manual:

-

@GiannisT No worries bud. Fowlers is a big dealership in the UK where a lot of people order their Yamaha parts from but if you're in Europe, CMSNL and Yamaha Amsterdam are also very good:

https://www.yamahacenteramsterdam.nl/en/

And Yamaha France parts lookup is the most accurate I've ever used, you can input your VIN number and it should find your bike:

https://www.yamaha-motor.eu/fr/fr/service-support/parts-catalogue/

The throttle cable splitter box is really simple, if you buy a genuine Yamaha cable by part number it comes assembled and complete and the balance mechanism is inside the box halfway down the cable where the two cables go to the carb and oil pump. You don't have to do anything to it apart from lubing it like any other cable, like I say it automatically balances the carb and oil pump at all throttle openings which is why genuine throttle cables for early bikes like yours don't have an adjuster on the oil pump cable. The TZR125 never had this, it was only the DTR as far as I know. Here's an explanation and pic from the Haynes manual:

@HOTSHOT-III ok thats plently comprehensive. I think i know what im looking for but ill be back for follow-ups if i get stuck anywhere. Thanks again

-

@GiannisT Hey bud,if you want parts get them from Yamaha Nikolakopoulos,they helped me a lot with my rebuild and get me everything, Even the most weird parts that I needed,it was a very worn abused bike.

-

Well i finally had the time to dive into it yesterday. pulled the engine out (which was a much bigger pain than anticipated) and dove into the top end. Needless to say, this is going to be a tricky one. Theres a huge chunk missing from the left side of my piston, plenty of coolant in the bottom end and the connecting rod is rattling left and right like a mf. Also it appears a metal headgasket was used(?). Since i wasnt mentally prepared to dive into the bottom end and fully rebuild this thing I am in grave need of all the help and advice i can get. Cheers

(also ive been trying to upload/link pictures and a video for like 20' now and i cant seem to figure it out)

-

Well i finally had the time to dive into it yesterday. pulled the engine out (which was a much bigger pain than anticipated) and dove into the top end. Needless to say, this is going to be a tricky one. Theres a huge chunk missing from the left side of my piston, plenty of coolant in the bottom end and the connecting rod is rattling left and right like a mf. Also it appears a metal headgasket was used(?). Since i wasnt mentally prepared to dive into the bottom end and fully rebuild this thing I am in grave need of all the help and advice i can get. Cheers

(also ive been trying to upload/link pictures and a video for like 20' now and i cant seem to figure it out)

Hey bud! Metal head gasket is standard. Con rod side to side movement is normal, they are never fixed ‘in place’. It’s purely the up and down play you don’t want. It would of been making a knocking noise before if it was bad.

I’d get someone with previous experience to have a look at the crank and bearings. If they’re ok just flush out the crank case and rebore and new piston that puppy!…

Host the pics on Imgur then copy the link.

On the toolbar (3rd from the SORRY! right) there’s an oblong box with what looks like a mountain with a moon In it. Click on that and paste your link in… -

Well i finally had the time to dive into it yesterday. pulled the engine out (which was a much bigger pain than anticipated) and dove into the top end. Needless to say, this is going to be a tricky one. Theres a huge chunk missing from the left side of my piston, plenty of coolant in the bottom end and the connecting rod is rattling left and right like a mf. Also it appears a metal headgasket was used(?). Since i wasnt mentally prepared to dive into the bottom end and fully rebuild this thing I am in grave need of all the help and advice i can get. Cheers

(also ive been trying to upload/link pictures and a video for like 20' now and i cant seem to figure it out)

@GiannisT If you do end up having to split the crankcases, here's the link to the crankcase splitter/crankshaft puller combo I used, these are made in the same factory as the "Tusk" branded version sold by Rocky Mountain ATVMC in the US but a lot cheaper:

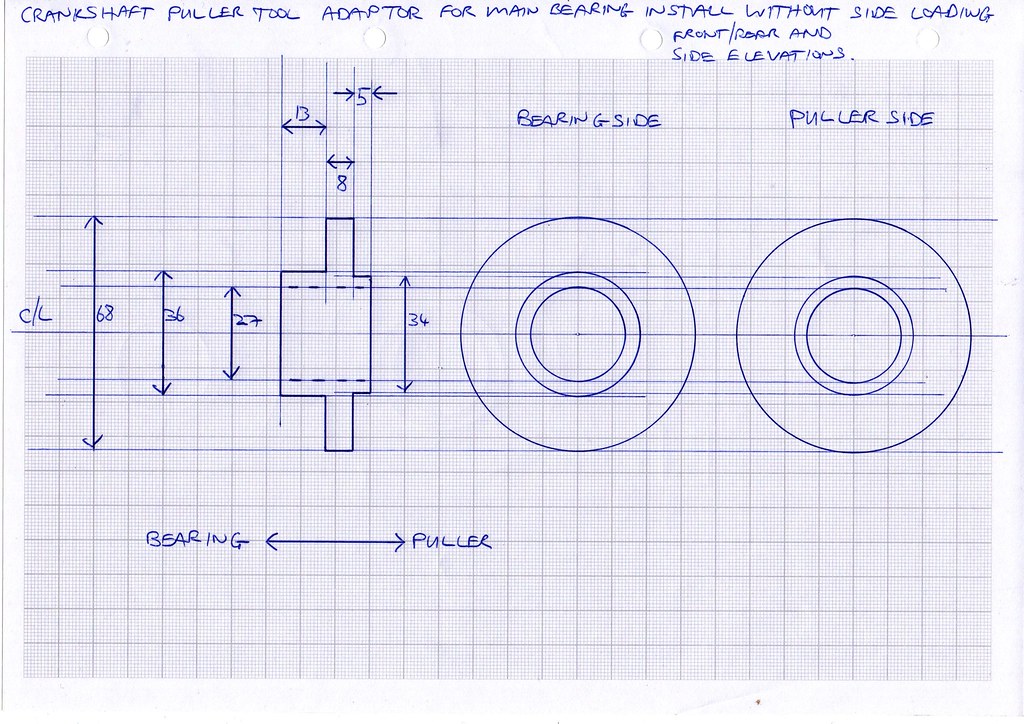

This is the adapter I had made for pulling the crankshaft back into the left main bearing to avoid transmitting a side load through the bearing (which will shorten its life). I had this made up at a local machine shop, you can see how it works, also check out the comments on this YouTube vid, lots of people saying the same thing:

https://www.youtube.com/watch?v=p0LK30KVWJg&t=1s

-

Hey bud! Metal head gasket is standard. Con rod side to side movement is normal, they are never fixed ‘in place’. It’s purely the up and down play you don’t want. It would of been making a knocking noise before if it was bad.

I’d get someone with previous experience to have a look at the crank and bearings. If they’re ok just flush out the crank case and rebore and new piston that puppy!…

Host the pics on Imgur then copy the link.

On the toolbar (3rd from the SORRY! right) there’s an oblong box with what looks like a mountain with a moon In it. Click on that and paste your link in… -

@SpookDog some side movement may be normal but i can’t possibly believe what im looking at is okay. Give this a look and give the video a listen:

-

Suggestion.

If you have never open an engine before see some extended video's rebuilding DTR engine. Take notes,ask and have a lot of patience. It's an engine that tou lay hands firts time.

I've opened my engine 6 times during the rebuild and had manufactured all the tools at the 3rd time. Had seen many video's.and read almost all this forum and the old archived one. -

That engine loos F@CKED lol.

The cylinder head is shot, the piston is half missing.

The piston is supposed to have float. What people are referring to is some minor "Big End" float on the crank shaft, not the piston float on the gudgeon pin. I highly doubt that engine seized on tickover, looks like piston "Death Ash", indicating that's been running lean for some time. The piston skirt is damaged and therefore it's probably gone into the bottom end.

-

That engine loos F@CKED lol.

The cylinder head is shot, the piston is half missing.

The piston is supposed to have float. What people are referring to is some minor "Big End" float on the crank shaft, not the piston float on the gudgeon pin. I highly doubt that engine seized on tickover, looks like piston "Death Ash", indicating that's been running lean for some time. The piston skirt is damaged and therefore it's probably gone into the bottom end.

-

@GiannisT The smart thing to do would be to tear it down and inspect/renew where appropriate. There is no shortcuts, one way or the other that engine is coming apart. If the swarf hasn't contaminated the main bearings it'll no doubt have damaged the big end bearing. Anything short cut you do will likely cause further harm and stress to other components causing bigger, more expensive, problems in the long run. That bike didn't die on tickover, going by the extent of the damage to that piston/head.

The head needs throwing in the bin, it's trashed. You might be able to get a tuner to alter the squishband and remove the detonation/debris marks from the head, but as it stands it's a glorified paper weight.

The problem with running damaged heads such as that, is that it encourages detonation, even if the jetting appears to be correct. In other words, it's just a shortcut to a blown engine, doubly frustrating when it's freshly built.

My advice, don't scrimp on critical components, it'll just come back to bite you.

You could spit the cases and inspect the components for wear. If all is in order then you may not need to renew (although I would anyway).

You could just inspect it in situ and see if the float is okay and if the big end bearing is damaged by checking for play. No way to tell about the mains or crankcase seals without tearing it apart. If debris has contaminated the seals then it will never idle/run right.