So Close!...

-

You can remove the swingarm while the engine is in the frame can’t you?…

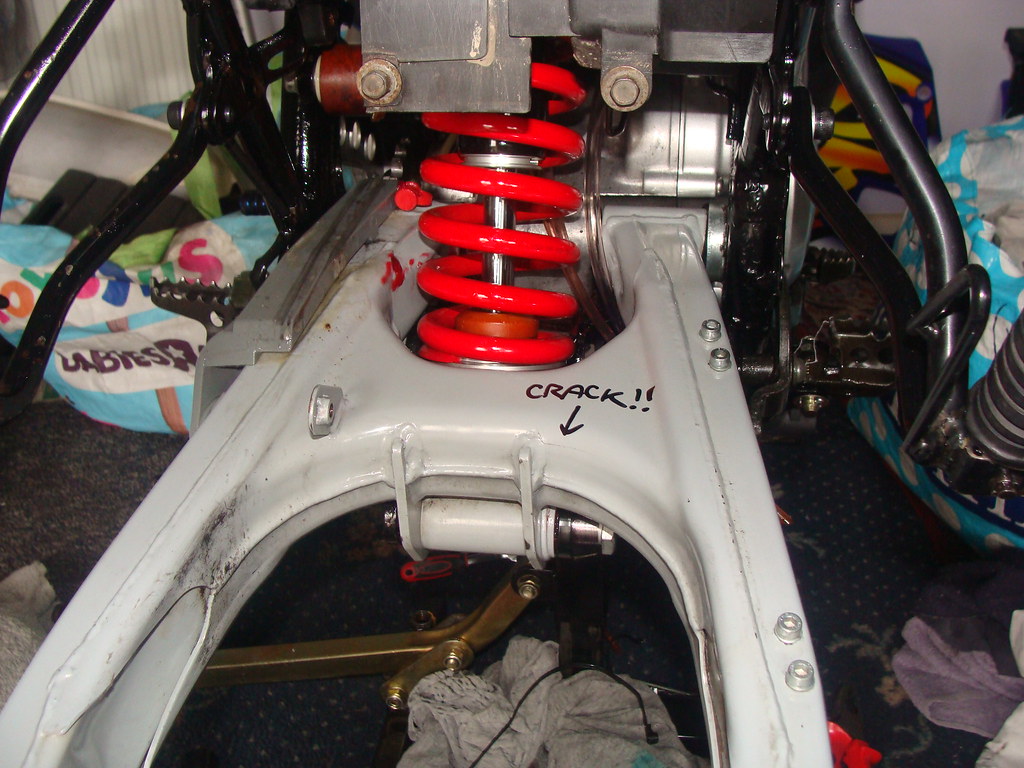

I’ve never done it, for some reason I didn’t think that you could!…@SpookDog Yes you can, I changed my swingarm without removing the shock and relay arm once. I'd arranged to go out riding with some mates the following morning, was just giving it a wipe over at about 10pm and found a crack near the relay arm mount so had to swap it out sharpish; luckily I had a spare with decent bearings. Still did the side clearance adjustment because I can't help myself

Another bulk order of 2am stress!

Another bulk order of 2am stress!

-

You can remove the swingarm while the engine is in the frame can’t you?…

I’ve never done it, for some reason I didn’t think that you could!… -

@SpookDog Same as an '85 YZ125, All Balls part number 29-5027, plenty on eBay around £15. The circlips are quite difficult to remove, I had to get inventive/sadistic with a set of jeweller's screwdrivers (which weren't much good for jewelling once I'd finished!):

https://www.allballsracing.com/29-5027.html

Simply Bearings sell the grease seals for this and the linkage for cheap (the 20 x 27 x 5mm ones for the linkage are better than stock as they're double lipped with a garter spring), it's quite handy to have a good supply of these:

Another hack you can do when assembling the linkage/relay arm is to flip the seals so the garter spring faces outwards away from the bearing; the lip without the spring is just a dust wiper so you can then cut small sections out of this with Swiss Army Knife scissors (best/sharpest scissors I've ever used) or one of those leather punches so when you re-lube the linkage bearings with a grease gun, the hydraulic pressure is less likely to force the seals out. The grease is free to pass through the gaps in the dust seal lip (now on the inside) and lift up the lip with the garter spring in its bid for freedom! The sprung lip then retracts, retaining enough grease inside the bearing and keeping dirt out.

If like me you're ham-fisted with the grease gun, it will still try and force out the seals so you can also hacksaw a section out of an M20 washer and insert it in the gap between the tiebars and the arm during greasing to prevent this (with the linkage bolted together and the seals where they should be, you can actually move the tiebar/sleeve assembly 2-3mm side to side; useful after you've greased up everything as you can move it fully each way to make it splodge the excess grease away from the bearings/seals, then clean it all off thoroughly to prevent any getting on the rear tyre).

-

@SpookDog Same as an '85 YZ125, All Balls part number 29-5027, plenty on eBay around £15. The circlips are quite difficult to remove, I had to get inventive/sadistic with a set of jeweller's screwdrivers (which weren't much good for jewelling once I'd finished!):

https://www.allballsracing.com/29-5027.html

Simply Bearings sell the grease seals for this and the linkage for cheap (the 20 x 27 x 5mm ones for the linkage are better than stock as they're double lipped with a garter spring), it's quite handy to have a good supply of these:

Another hack you can do when assembling the linkage/relay arm is to flip the seals so the garter spring faces outwards away from the bearing; the lip without the spring is just a dust wiper so you can then cut small sections out of this with Swiss Army Knife scissors (best/sharpest scissors I've ever used) or one of those leather punches so when you re-lube the linkage bearings with a grease gun, the hydraulic pressure is less likely to force the seals out. The grease is free to pass through the gaps in the dust seal lip (now on the inside) and lift up the lip with the garter spring in its bid for freedom! The sprung lip then retracts, retaining enough grease inside the bearing and keeping dirt out.

If like me you're ham-fisted with the grease gun, it will still try and force out the seals so you can also hacksaw a section out of an M20 washer and insert it in the gap between the tiebars and the arm during greasing to prevent this (with the linkage bolted together and the seals where they should be, you can actually move the tiebar/sleeve assembly 2-3mm side to side; useful after you've greased up everything as you can move it fully each way to make it splodge the excess grease away from the bearings/seals, then clean it all off thoroughly to prevent any getting on the rear tyre).

Thank you bud!…

I definitely need to make a really sharp pick, to try and lift an end. I just need to remove the swivel bit from the old one to reuse, just until I can get one ordered and posted. I can’t wait to get this bike back together and ride it!

The shock I’m using had a solid steel ‘bush’ in it that I had to put 2 cuts into, just so I could remove it!…

I really appreciate the lube tips you’ve posted, especially the PV cable oilers with stainless steel inners! It’s so important but so overlooked. I bought a swingarm that was going cheap because it is one with the grease nipples on. Why they stopped fitting them is beyond me…

-

@SpookDog Same as an '85 YZ125, All Balls part number 29-5027, plenty on eBay around £15. The circlips are quite difficult to remove, I had to get inventive/sadistic with a set of jeweller's screwdrivers (which weren't much good for jewelling once I'd finished!):

https://www.allballsracing.com/29-5027.html

Simply Bearings sell the grease seals for this and the linkage for cheap (the 20 x 27 x 5mm ones for the linkage are better than stock as they're double lipped with a garter spring), it's quite handy to have a good supply of these:

Another hack you can do when assembling the linkage/relay arm is to flip the seals so the garter spring faces outwards away from the bearing; the lip without the spring is just a dust wiper so you can then cut small sections out of this with Swiss Army Knife scissors (best/sharpest scissors I've ever used) or one of those leather punches so when you re-lube the linkage bearings with a grease gun, the hydraulic pressure is less likely to force the seals out. The grease is free to pass through the gaps in the dust seal lip (now on the inside) and lift up the lip with the garter spring in its bid for freedom! The sprung lip then retracts, retaining enough grease inside the bearing and keeping dirt out.

If like me you're ham-fisted with the grease gun, it will still try and force out the seals so you can also hacksaw a section out of an M20 washer and insert it in the gap between the tiebars and the arm during greasing to prevent this (with the linkage bolted together and the seals where they should be, you can actually move the tiebar/sleeve assembly 2-3mm side to side; useful after you've greased up everything as you can move it fully each way to make it splodge the excess grease away from the bearings/seals, then clean it all off thoroughly to prevent any getting on the rear tyre).

That’s weird! Your post about the swingarm just appeared! Spooky!

Is that a toolbox behind the expansion tank? Standard? There are so many clips, guides and bolt-on bits I know nothing about because the previous owners have deleted so much! …

———————

Also: That’s quite a harem you have there!

-

That’s weird! Your post about the swingarm just appeared! Spooky!

Is that a toolbox behind the expansion tank? Standard? There are so many clips, guides and bolt-on bits I know nothing about because the previous owners have deleted so much! …

———————

Also: That’s quite a harem you have there!

@SpookDog Thanks man

Yes that is a toolbox, it's there because the original DT125RE from the 90s takes a bigger battery than the DTR which occupies the space where the toolkit would normally go on electric start versions. This was my 70,000km '98 3MB French bike (the Starship Enterprise Paris commuting mileage plus some sky/ground style greenlaning by me I guess might explain the cracked swingarm).

Yes that is a toolbox, it's there because the original DT125RE from the 90s takes a bigger battery than the DTR which occupies the space where the toolkit would normally go on electric start versions. This was my 70,000km '98 3MB French bike (the Starship Enterprise Paris commuting mileage plus some sky/ground style greenlaning by me I guess might explain the cracked swingarm).The bike behind it is the '93 3NC I did the engine rebuild on last year with Top Racing crankshaft, Athena 125cc top end etc. The new owner is very happy with it and reports it is very fast (the Athena 125cc barrel has slightly more aggressive porting than stock). Both sadly gone now, I only rode that bike a few times after the rebuild to make sure it ran properly so never got to test it thoroughly.

-

@SpookDog Thanks man

Yes that is a toolbox, it's there because the original DT125RE from the 90s takes a bigger battery than the DTR which occupies the space where the toolkit would normally go on electric start versions. This was my 70,000km '98 3MB French bike (the Starship Enterprise Paris commuting mileage plus some sky/ground style greenlaning by me I guess might explain the cracked swingarm).

Yes that is a toolbox, it's there because the original DT125RE from the 90s takes a bigger battery than the DTR which occupies the space where the toolkit would normally go on electric start versions. This was my 70,000km '98 3MB French bike (the Starship Enterprise Paris commuting mileage plus some sky/ground style greenlaning by me I guess might explain the cracked swingarm).The bike behind it is the '93 3NC I did the engine rebuild on last year with Top Racing crankshaft, Athena 125cc top end etc. The new owner is very happy with it and reports it is very fast (the Athena 125cc barrel has slightly more aggressive porting than stock). Both sadly gone now, I only rode that bike a few times after the rebuild to make sure it ran properly so never got to test it thoroughly.

Stumbled across an easy way of getting the C rings out of the lower shock bush! I used a small screwdriver and tapped it down against the ring at a 45* angle, it ‘shocked’ the ring back and up and the screwdriver head slipped underneath it both times! Easy days! Last night’s attempts, I don’t want to talk about though

Age’s spent picking, prying and trying to get leverage!…

Age’s spent picking, prying and trying to get leverage!…

‘New’ shock fitted with correct bottom bush…

Edit: tried it on another shock without success. It seems important that the C ring isn’t corroded in place, that it can be tapped around the groove freely. Obvious with hindsight

PS discovered some play in the linkage ‘dog bones’. They are the expensive bushes to replace aren’t they?…

-

Stumbled across an easy way of getting the C rings out of the lower shock bush! I used a small screwdriver and tapped it down against the ring at a 45* angle, it ‘shocked’ the ring back and up and the screwdriver head slipped underneath it both times! Easy days! Last night’s attempts, I don’t want to talk about though

Age’s spent picking, prying and trying to get leverage!…

Age’s spent picking, prying and trying to get leverage!…

‘New’ shock fitted with correct bottom bush…

Edit: tried it on another shock without success. It seems important that the C ring isn’t corroded in place, that it can be tapped around the groove freely. Obvious with hindsight

PS discovered some play in the linkage ‘dog bones’. They are the expensive bushes to replace aren’t they?…

@SpookDog I hate to tell you this, but the airbox is very difficult to refit with the shock in place (and easy with it removed so hope you haven't done any more since this pic was taken).

RE the linkage bearings, the relay arm needle rollers are quite expensive from Yamaha (£38 ea.) but you can get the same size bearing here:

https://shop.marksman-ind.com/93315-32052-00-equivalent-yamaha-bearing-29446-p.asp

Bushes for the other two linkage pivots (the ones at either end of the tiebars) can be got cheap here:

The part you need from Fowlers etc are the sleeves, someone on eBay sells a complete linkage repair kit which includes them but it's £110 and the sleeves don't have the 2mm holes which enable the grease to pass from the grease nipple, through the bolt and sleeve and into the bearing. So probably best to buy these genuine, the long ones are £26.50 and the relay arm one is £20. Although TBH I've never known these to be excessively worn, if they're close to 20mm OD I'd try the bushes and roller bearing first.

Looking good

-

@SpookDog I hate to tell you this, but the airbox is very difficult to refit with the shock in place (and easy with it removed so hope you haven't done any more since this pic was taken).

RE the linkage bearings, the relay arm needle rollers are quite expensive from Yamaha (£38 ea.) but you can get the same size bearing here:

https://shop.marksman-ind.com/93315-32052-00-equivalent-yamaha-bearing-29446-p.asp

Bushes for the other two linkage pivots (the ones at either end of the tiebars) can be got cheap here:

The part you need from Fowlers etc are the sleeves, someone on eBay sells a complete linkage repair kit which includes them but it's £110 and the sleeves don't have the 2mm holes which enable the grease to pass from the grease nipple, through the bolt and sleeve and into the bearing. So probably best to buy these genuine, the long ones are £26.50 and the relay arm one is £20. Although TBH I've never known these to be excessively worn, if they're close to 20mm OD I'd try the bushes and roller bearing first.

Looking good

@HOTSHOT-III Is it? I'm sure I get mine in and out no dramas. I always want to have it removed as it serves no purpose on my bike other than a battery holder and a rear mud guard.

-

@SpookDog I hate to tell you this, but the airbox is very difficult to refit with the shock in place (and easy with it removed so hope you haven't done any more since this pic was taken).

RE the linkage bearings, the relay arm needle rollers are quite expensive from Yamaha (£38 ea.) but you can get the same size bearing here:

https://shop.marksman-ind.com/93315-32052-00-equivalent-yamaha-bearing-29446-p.asp

Bushes for the other two linkage pivots (the ones at either end of the tiebars) can be got cheap here:

The part you need from Fowlers etc are the sleeves, someone on eBay sells a complete linkage repair kit which includes them but it's £110 and the sleeves don't have the 2mm holes which enable the grease to pass from the grease nipple, through the bolt and sleeve and into the bearing. So probably best to buy these genuine, the long ones are £26.50 and the relay arm one is £20. Although TBH I've never known these to be excessively worn, if they're close to 20mm OD I'd try the bushes and roller bearing first.

Looking good

Went in OK!

…

…Cheers for the links! I can’t remember which of the two linkage ‘pivots’ has all the loose needle roller bearings, but the one that’s showing play is the one that fits to the dogbones (I can see it move up & down clearly) Not the frame one…

-

Went in OK!

…

…Cheers for the links! I can’t remember which of the two linkage ‘pivots’ has all the loose needle roller bearings, but the one that’s showing play is the one that fits to the dogbones (I can see it move up & down clearly) Not the frame one…

@SpookDog @Calum It may be that I took that view is because the only reason I've ever taken my airbox out is to seal up where the rubber joins the plastic, and I was thinking of your fresh paintwork

Still all good if it went in OK.

Still all good if it went in OK.The bearings at both ends of the tiebars are the ones with plain bushes, the needle roller bearings go where the relay arm attaches to the frame.

-

@SpookDog @Calum It may be that I took that view is because the only reason I've ever taken my airbox out is to seal up where the rubber joins the plastic, and I was thinking of your fresh paintwork

Still all good if it went in OK.

Still all good if it went in OK.The bearings at both ends of the tiebars are the ones with plain bushes, the needle roller bearings go where the relay arm attaches to the frame.

I sure as shit have had problems removing the air box. It was mainly (IIRC!) because the rubber mudguard bolts had seized in so the nuts spun. It wouldn’t let me separate the battery tray section…

Reminds me! I’ve got to epoxy the weird nuts back in place!…

Have a good time this x~mas everyone!…

-

I sure as shit have had problems removing the air box. It was mainly (IIRC!) because the rubber mudguard bolts had seized in so the nuts spun. It wouldn’t let me separate the battery tray section…

Reminds me! I’ve got to epoxy the weird nuts back in place!…

Have a good time this x~mas everyone!…

-

@SpookDog I had the same problem for years and had it just "cable tied" to the frame at the top. But when the bike went a rebuild I drilled it out and used a bolt that isn't made of cheese.

I meant the rubber mud flap that ties the air box to the battery tray! But yes, I need many weld~fills, drill & tap fixes all over my frame!

…

…Slow going:

Every part I go to put back on needs cleaning at least, usually mending and a coat of satin black. I just spent 3 hours on the speedo and rev counter! Oh well, nobody ever said it was going to be easy!

…

…Pick up, shake head, wire brush, paint! Seems to be my mantra!…

-

I meant the rubber mud flap that ties the air box to the battery tray! But yes, I need many weld~fills, drill & tap fixes all over my frame!

…

…Slow going:

Every part I go to put back on needs cleaning at least, usually mending and a coat of satin black. I just spent 3 hours on the speedo and rev counter! Oh well, nobody ever said it was going to be easy!

…

…Pick up, shake head, wire brush, paint! Seems to be my mantra!…

-

Emergency! I need 2 x 70mm M6! bolts to fit my stator on! If you have any please let me know…

-

Emergency! I need 2 x 70mm M6! bolts to fit my stator on! If you have any please let me know…

Cheers Ollie! I PM’d my addy…

—————————

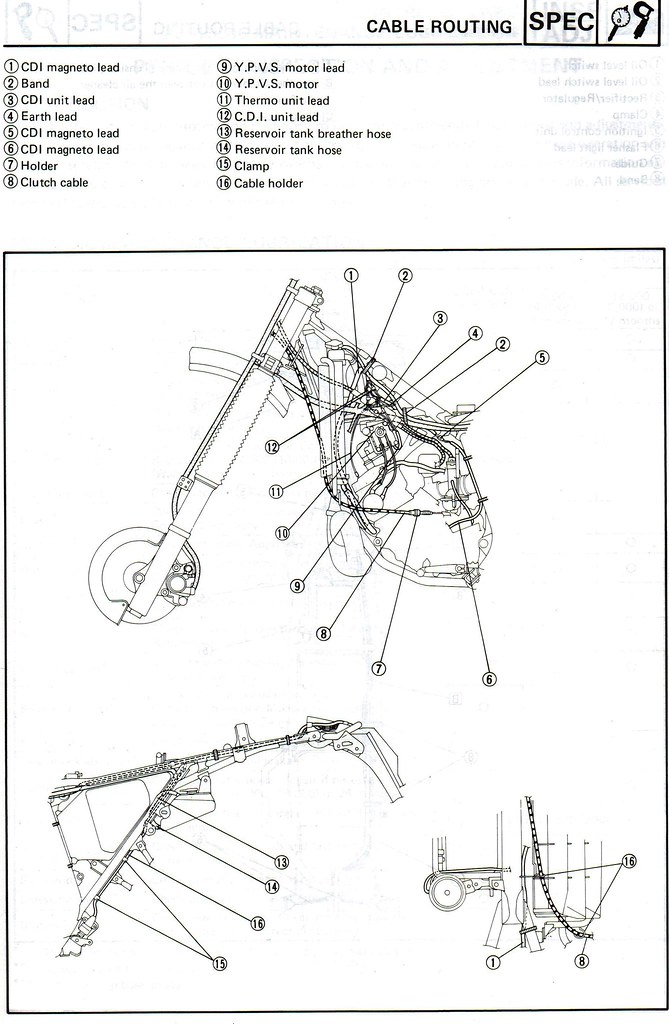

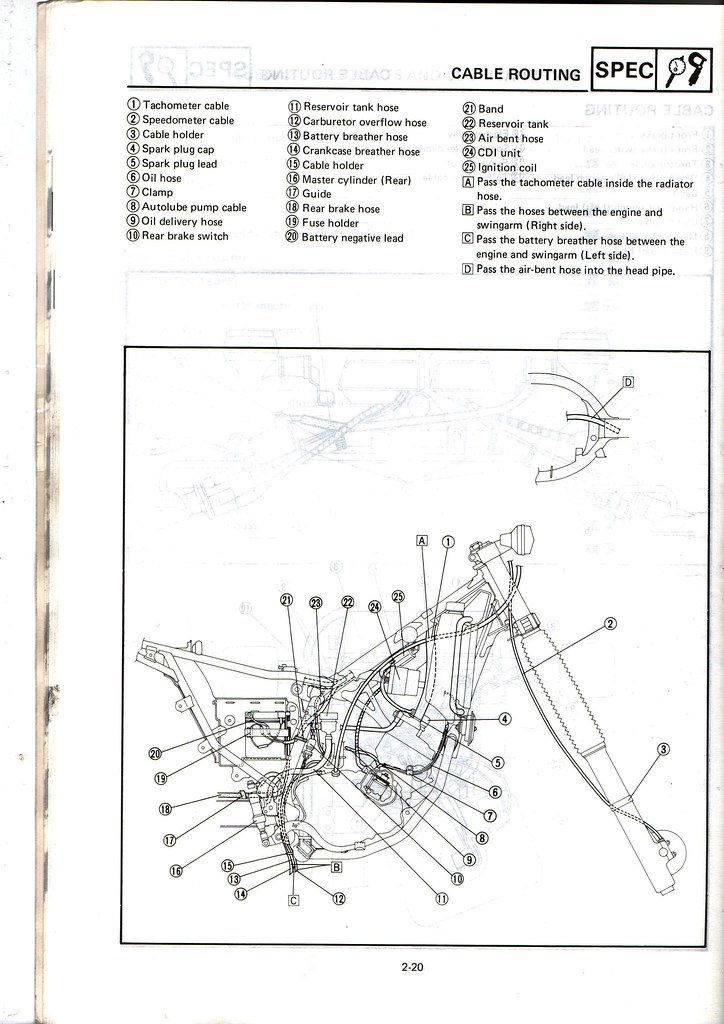

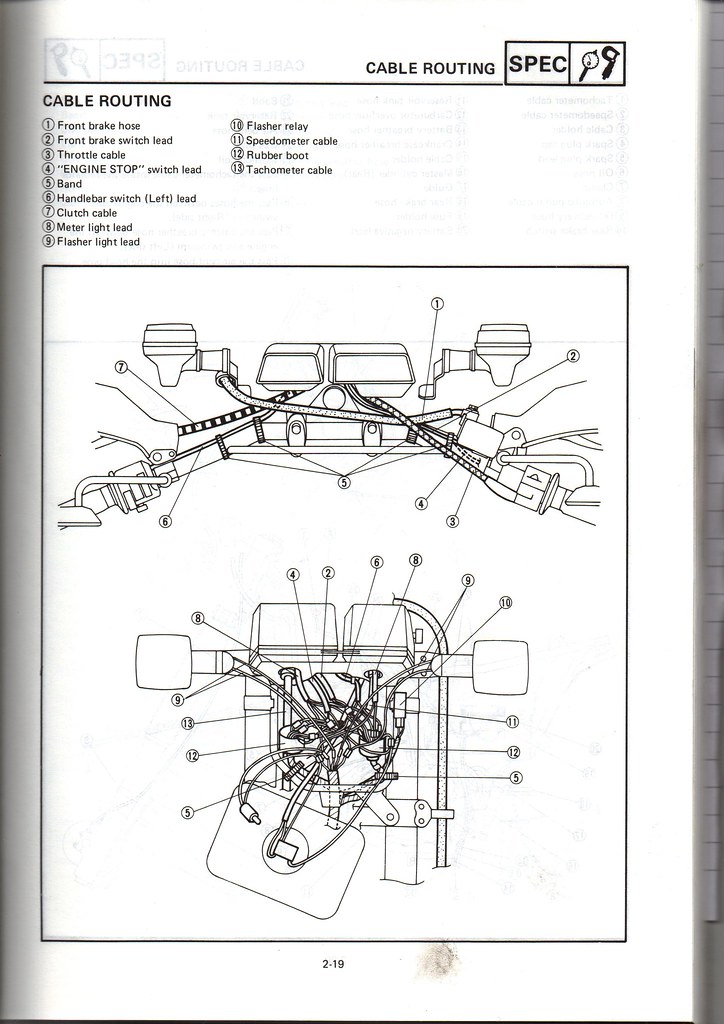

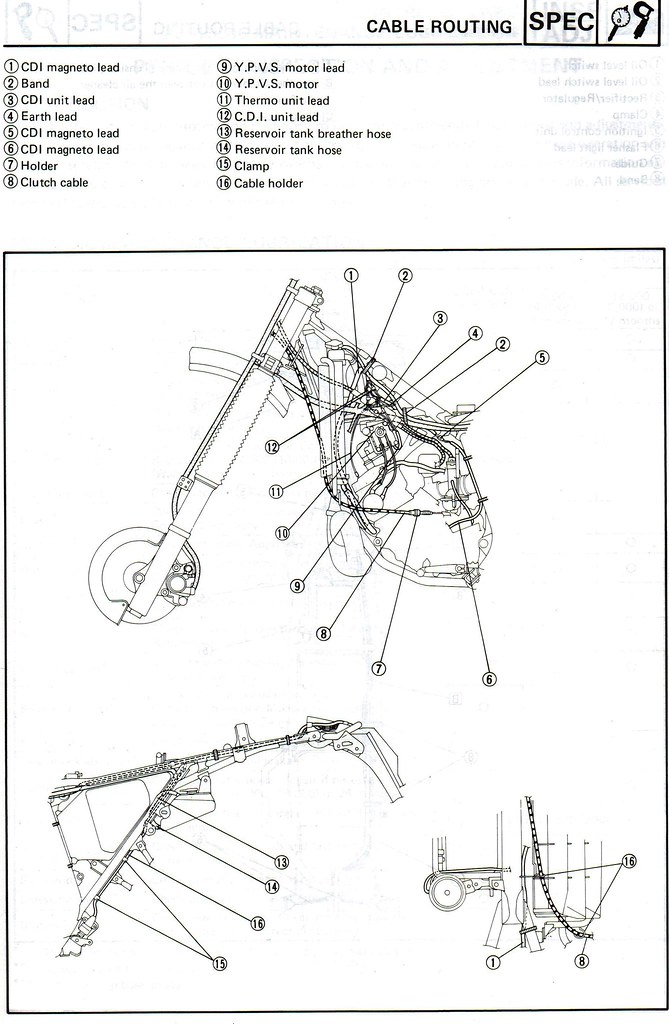

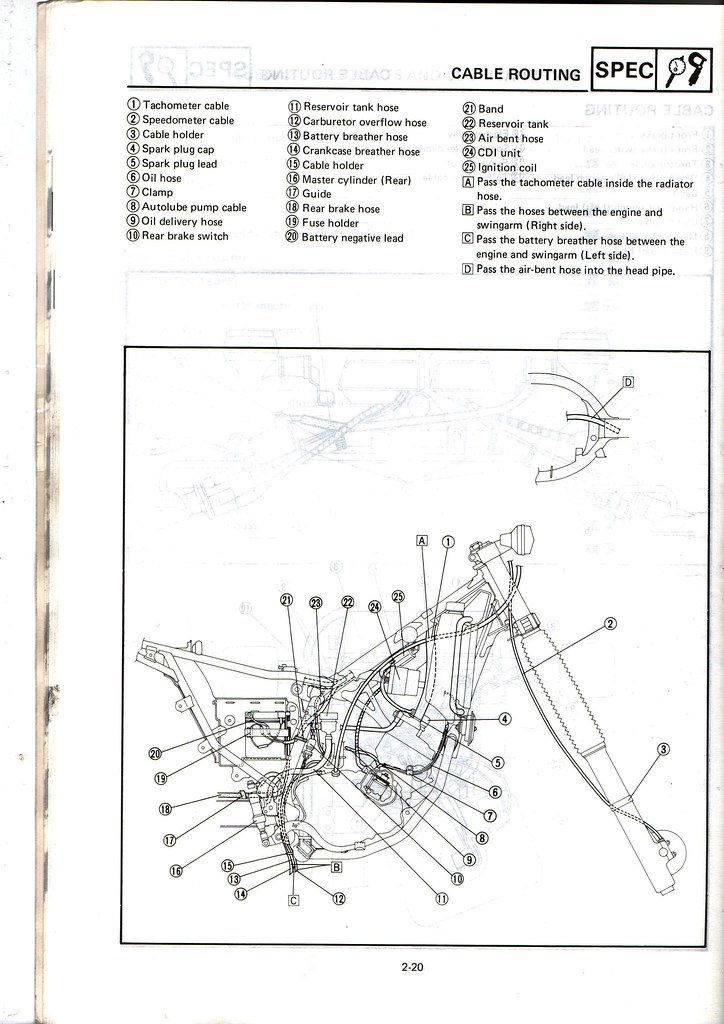

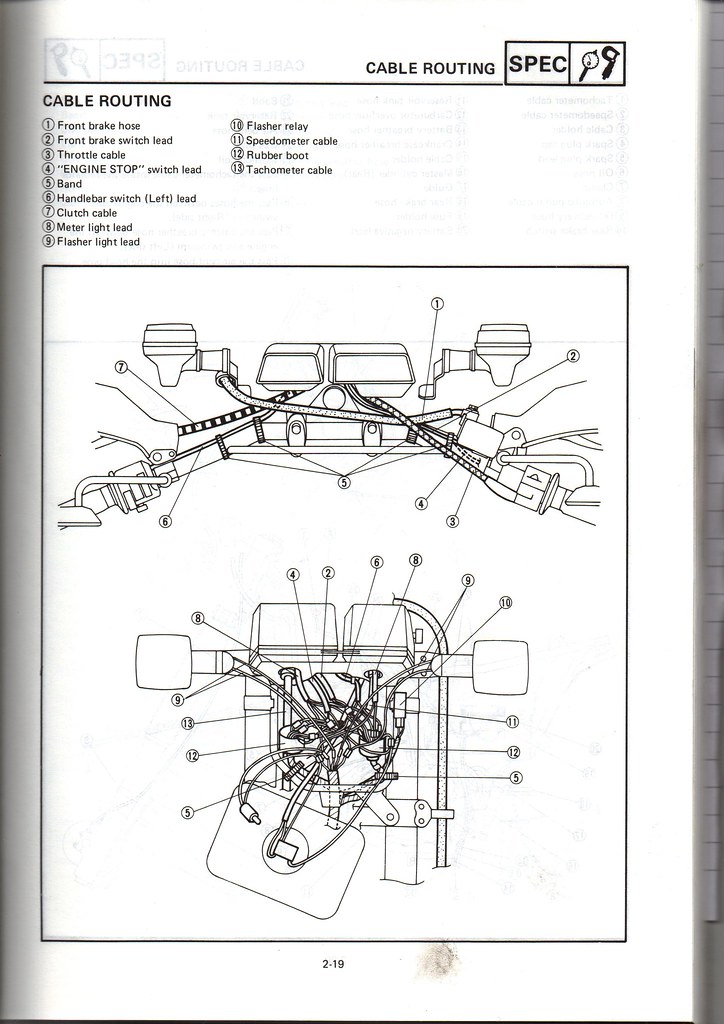

Does anyone have any pics of a bike with the seat & tank off that shows where the wiring loom is supposed to be situated/routed? Big help if possible!

…

…

I fuxin dread this bit! 35 year old wire and all the previous ‘mowners’ tinkering!…

For some reason this is taking a lot longer than I thought it would! I spend more time staring at it than I do assembling it! Then mending & cleaning whatever part I pick up to bolt on!

Anybody want to do a lottery as to when it’s together and riding? How many daze?!

…

… -

Cheers Ollie! I PM’d my addy…

—————————

Does anyone have any pics of a bike with the seat & tank off that shows where the wiring loom is supposed to be situated/routed? Big help if possible!

…

…

I fuxin dread this bit! 35 year old wire and all the previous ‘mowners’ tinkering!…

For some reason this is taking a lot longer than I thought it would! I spend more time staring at it than I do assembling it! Then mending & cleaning whatever part I pick up to bolt on!

Anybody want to do a lottery as to when it’s together and riding? How many daze?!

…

…@SpookDog Here you go bud, hot off the Yamaha presses:

IIRC the biggest PITA is the expansion tank hose where it goes round the back of the airbox, the original tube is shaped to fit around these bends but mine were always knackered so I experimented with various eBay tubes. I think the best results I had were with that clear braided stuff (like garden hose but in about 8mm ID) but even if you stick to this the quality varies, once I had to put some 4mm ID tube inside that to stop it getting kinked.

-

@SpookDog Here you go bud, hot off the Yamaha presses:

IIRC the biggest PITA is the expansion tank hose where it goes round the back of the airbox, the original tube is shaped to fit around these bends but mine were always knackered so I experimented with various eBay tubes. I think the best results I had were with that clear braided stuff (like garden hose but in about 8mm ID) but even if you stick to this the quality varies, once I had to put some 4mm ID tube inside that to stop it getting kinked.

Cheers bud! I forgot to fuxin fit that! I’ve actually got a good condition one to go on there. It’s amazing how so many hours work can look like so little progress!

…

…