What was I thinking!…

-

It’s a UK 1994 Tzr125rr (4hw) it was a small production number 125 model that used the frame from a 3xv Tzr250rr. It doesn’t have the belgarda Alu swingarm or polini alu forks. It has steel ones. Bit of a bitza

whatever you had left in the parts bin job…

whatever you had left in the parts bin job…It didn’t have a carb when I got it. I bought a 28mm Mikuni for it from fleabay a while ago but haven’t tried it yet…

Good price for the carb?…

Also it’s listed as a flatslide but the slide body has a round cap?…

@SpookDog The Dell'Orto looks good for the money but the UK TZR125R 4HW ran the TM28SS as per DTR with a few minor changes so if you have one I'd stick with that. A lot of two-stroke tuners run into problems bolting on bigger carbs as it tends to reduce low-end power without really improving the top end.

I always preferred the UK version to the Belgarda TBH, smiley face headlight makes it look identical to the V-Twin TZR250. I have a TZR125R Service Information book I downloaded for free on PDF; it's in French but maybe @Calum or someone can advise me whether it's possible to upload it onto here.

Also agree with @MadGyver ; change every seal in the engine if it's been stood for any length of time. Koyo gearbox bearings are pretty cheap from PJME and at the risk of banging on about the virtues of the Top Racing/Jasil crankshaft, a French company makes an adapter so you can run one in a DTRe engine. It's just a thin cone-shaped piece of steel which fits onto the crank taper before the DTRe flywheel, and has a slot so it can fit over the woodruff key:

To remove the DTRe flywheel I think you need a harmonic balance puller like this one:

https://www.machinemart.co.uk/p/clarke-cht698-46-piece-harmonic-balance-puller/

-

@SpookDog If I were you I would change every seals in the engine.If it was sitting for so long don't trust them even with low miles.

Cheers guys, it’s just I only have cheap OEM (SKF & some I’ve not heard of) seals to throw at this. I am dust poor. I’ve never been able to afford dirt

Then again, they may not have the lifespan of genuine seals but they will work for as long as I need them to. (I had a set in for 20K miles in the Dtr) They can always be changed out later…Just thought I’d check the air box to carb rubber size. It fits a 28 Mikuni. No way it’d fit the dellorto. I was led to believe that my bike took a 32 dellorto, iirc. I guess not…

The 28mm I got has a different needle & tube than the dtr. Haven’t checked the valve cutaway yet, but I’m confident it’s good for the motor…

-

Just whipped of the pump cover and oil has filled up in there. Hopefully past the seal!

…

…Edit:

Removed the clutch casing.

The gasket is perfect. I’m gonna check out the pump seal next. I can’t imagine oil getting past it but this motor might of been sitting for 10 years for all I know. There was oil in the impeller anyways…PS any tip on removing the water pump seal? She doesn’t want to move

-

Cheers guys, it’s just I only have cheap OEM (SKF & some I’ve not heard of) seals to throw at this. I am dust poor. I’ve never been able to afford dirt

Then again, they may not have the lifespan of genuine seals but they will work for as long as I need them to. (I had a set in for 20K miles in the Dtr) They can always be changed out later…Just thought I’d check the air box to carb rubber size. It fits a 28 Mikuni. No way it’d fit the dellorto. I was led to believe that my bike took a 32 dellorto, iirc. I guess not…

The 28mm I got has a different needle & tube than the dtr. Haven’t checked the valve cutaway yet, but I’m confident it’s good for the motor…

@SpookDog SKF are good oil seals, and a lot of people use the £25 Yambits engine seal kit with no issues. As long as they're new they should last a fair while.

Just had a read through my TZR-R 4HW service information and the TM28SS jet sizes are:

Main #210

Emulsion tube P-2

Needle 5H38-2, 4th clip position from top

Pilot #17.5It doesn't mention power jet size or slide cutaway but the slide has a 3XV part number on Fowlers so the same as the V-Twin TZR250.

So I guess pilot jet from @markus-w 's eBay source and Allens Performance can probably order the emulsion tube and needle if you want to try them.

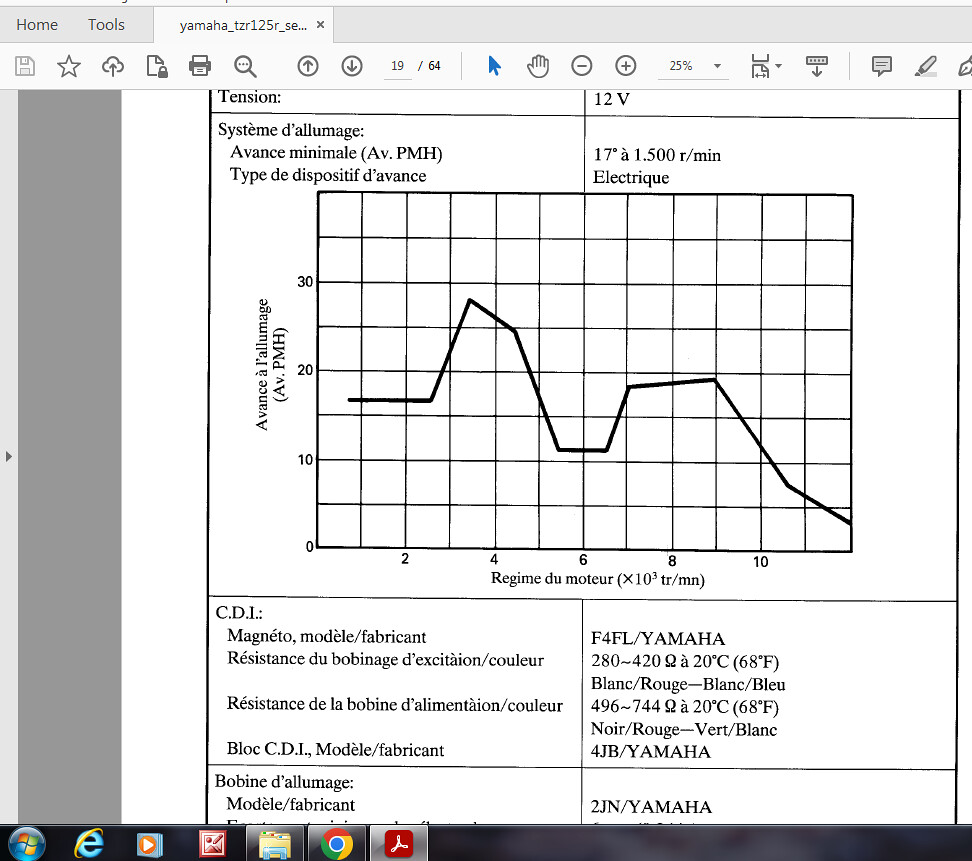

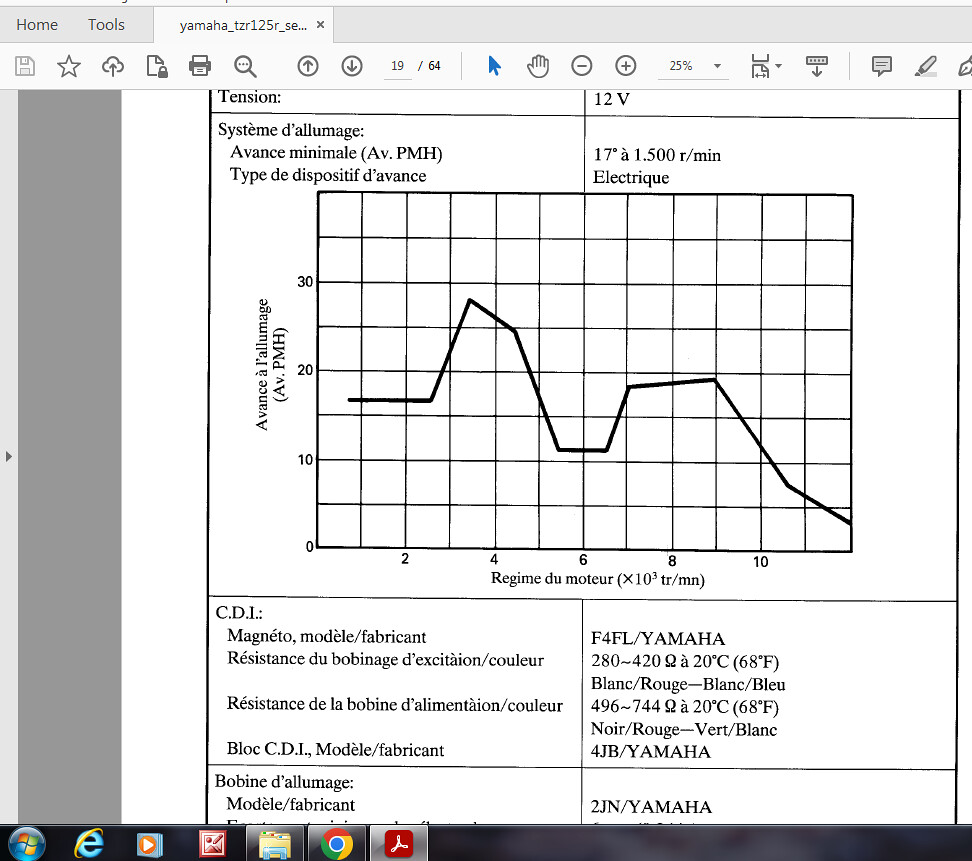

Ignition advance curve looks very different to the DTR as well, the 3MB is very linear in comparison. I think the 4HW is like this to make it stronger at higher RPM, like between 8-12k whereas the 3MB curve is probably meant to deliver a wider spread of power which is better suited to off-road riding. So from what I can see the 4HW is designed to rev to these kinds of speeds where a good 3MB tops out at around 10,500.

The 3-wire servo also has a 4FL part number on Fowlers so the onboard computer inside it is probably different to the 3MB servo, again to maximise efficiency at higher engine speeds I'd imagine. The PV operating at a different engine speed to the 3MB could explain the strange trough in advance between 5.5-6.5k RPM.

With all this in mind I'd definitely start with stock 4HW jetting and a new or rebuilt crankshaft. IIRC these also had a plated bore (in common with the V-twin) which manufacturers had to move towards for more efficient heat transfer into the water jacket on two-strokes in a higher state of tune (for example the parrallel twin TZR250 had steel liners whereas the RGV250 and KR1-S both ran plated bores and made a lot more power than the PT TZR250). So maybe bear this in mind as well. Not 100% sure on all this (it's been a while) so I'll have a read of A. Graham Bell later if I get time.

-

@SpookDog SKF are good oil seals, and a lot of people use the £25 Yambits engine seal kit with no issues. As long as they're new they should last a fair while.

Just had a read through my TZR-R 4HW service information and the TM28SS jet sizes are:

Main #210

Emulsion tube P-2

Needle 5H38-2, 4th clip position from top

Pilot #17.5It doesn't mention power jet size or slide cutaway but the slide has a 3XV part number on Fowlers so the same as the V-Twin TZR250.

So I guess pilot jet from @markus-w 's eBay source and Allens Performance can probably order the emulsion tube and needle if you want to try them.

Ignition advance curve looks very different to the DTR as well, the 3MB is very linear in comparison. I think the 4HW is like this to make it stronger at higher RPM, like between 8-12k whereas the 3MB curve is probably meant to deliver a wider spread of power which is better suited to off-road riding. So from what I can see the 4HW is designed to rev to these kinds of speeds where a good 3MB tops out at around 10,500.

The 3-wire servo also has a 4FL part number on Fowlers so the onboard computer inside it is probably different to the 3MB servo, again to maximise efficiency at higher engine speeds I'd imagine. The PV operating at a different engine speed to the 3MB could explain the strange trough in advance between 5.5-6.5k RPM.

With all this in mind I'd definitely start with stock 4HW jetting and a new or rebuilt crankshaft. IIRC these also had a plated bore (in common with the V-twin) which manufacturers had to move towards for more efficient heat transfer into the water jacket on two-strokes in a higher state of tune (for example the parrallel twin TZR250 had steel liners whereas the RGV250 and KR1-S both ran plated bores and made a lot more power than the PT TZR250). So maybe bear this in mind as well. Not 100% sure on all this (it's been a while) so I'll have a read of A. Graham Bell later if I get time.

Thank you for some truly useful information. I take my hat off!

The carb I bought for it has a 38 on the needle or emulsion tube IIRC. The 210 & 17.5 sounds familiar as well. I’ll dig it out and check in a mo…

I’ve got a 3mb-p barrel @ head freshly re~bored to go on it. A 4fu is standard I believe. I think the reason for nicasil lining is more to do with cost of production than anything (the heat transfer is tiny and irrelevant IMO when you trade it off for ‘serviceability’). I’d personally rather have a cast iron liner. I’m planning on getting one of my 4fu barrels relined by PJME at some point when I have a spare £150. Match the porting to the CDI & power valve that are on the bike (thanks again for the info!!) Thank fux that it’s all there apart from the seat & lower fairing plastics!

…

… -

My carb is:

505 P-2 on the emulsion tube

5H 38 on the needle

1mm cutaway on the slide valve

210 main jet

17.5 pilot jet

I think I got lucky on the carb I bought

wasn’t too bad @ under £50 IIRC

wasn’t too bad @ under £50 IIRC

Thanks again, again! That’s given me some peace of mind…PS I’ve got an harmonic balancer puller coming so I can get to and replace the crank seal on that side…

In an ideal life, I’d replace every single bearing, seal and gasket. The thing is that this is a shoestring budget. I’ll do everything I can not to make the same mistakes as I did when I built the Dt. Considering it was the first bike I’ve worked on or owned in over 25 years, I’m not gonna beat myself up…

Thing is, this isn’t a restoration. It’s a resuscitation!!

-

My carb is:

505 P-2 on the emulsion tube

5H 38 on the needle

1mm cutaway on the slide valve

210 main jet

17.5 pilot jet

I think I got lucky on the carb I bought

wasn’t too bad @ under £50 IIRC

wasn’t too bad @ under £50 IIRC

Thanks again, again! That’s given me some peace of mind…PS I’ve got an harmonic balancer puller coming so I can get to and replace the crank seal on that side…

In an ideal life, I’d replace every single bearing, seal and gasket. The thing is that this is a shoestring budget. I’ll do everything I can not to make the same mistakes as I did when I built the Dt. Considering it was the first bike I’ve worked on or owned in over 25 years, I’m not gonna beat myself up…

Thing is, this isn’t a restoration. It’s a resuscitation!!

Got the puller and got the flywheel off. Got the crank seals out, I can see nothing wrong with the bearings and there’s no movement, I don’t like the sound of them though. I’m not an expert and have nothing to compare them with. There is a regular beat/change in noise to them that I don’t like though. I’ve got a new pair of Koyo bearings that I’m gonna put in them once I’ve had the run-out checked on the crank…

-

Got the puller and got the flywheel off. Got the crank seals out, I can see nothing wrong with the bearings and there’s no movement, I don’t like the sound of them though. I’m not an expert and have nothing to compare them with. There is a regular beat/change in noise to them that I don’t like though. I’ve got a new pair of Koyo bearings that I’m gonna put in them once I’ve had the run-out checked on the crank…

-

I have never needed it, a slight tap with a rubber mallet sorts it out.

But you should be able to apply some pressure to the crank end to ease off the cases.

I’ve seen some casings that have been chiselled apart! I’ve been guilty of the same in my yoof, I don’t doubt 🥴

I put a little bit of pressure on it then tapped the cases with a hubber rammer, it popped apart lovely. Only wish I could of left both bearings in the casings. I did try heating the tight bearing to get it to let go of the crank. No joy tho’

I just need to get a ‘clamshell’ bearing puller now. No more levering away with flathead screwdrivers!…

I just need to get a ‘clamshell’ bearing puller now. No more levering away with flathead screwdrivers!…I really need to start prioritising the two bikes now. I’ve got everything to rebuild a tight, righteous motor for the Dtr, but I want to strip, dip & coat the frame, ect. As well as making a new loom. I really need to get the Tzr running and throw an mot at it to make a daily while I work out the Dtr. I think I’m gonna have to keep limping along the leperous motor that’s in the Dtr some more. It hasn’t stranded me yet in over 25K smiles

…

… -

I’ve seen some casings that have been chiselled apart! I’ve been guilty of the same in my yoof, I don’t doubt 🥴

I put a little bit of pressure on it then tapped the cases with a hubber rammer, it popped apart lovely. Only wish I could of left both bearings in the casings. I did try heating the tight bearing to get it to let go of the crank. No joy tho’

I just need to get a ‘clamshell’ bearing puller now. No more levering away with flathead screwdrivers!…

I just need to get a ‘clamshell’ bearing puller now. No more levering away with flathead screwdrivers!…I really need to start prioritising the two bikes now. I’ve got everything to rebuild a tight, righteous motor for the Dtr, but I want to strip, dip & coat the frame, ect. As well as making a new loom. I really need to get the Tzr running and throw an mot at it to make a daily while I work out the Dtr. I think I’m gonna have to keep limping along the leperous motor that’s in the Dtr some more. It hasn’t stranded me yet in over 25K smiles

…

… -

Anybody know about upside down fork stantion replacement? Can the aluminium bottoms be separated from the chromed steel tubes? Or are they fixed? Cheers…

-

Anybody know about upside down fork stantion replacement? Can the aluminium bottoms be separated from the chromed steel tubes? Or are they fixed? Cheers…

@SpookDog In the 90s I replaced a USD fork stanchion on a GSX-R400 GK76A with 41mm Kayaba forks. They were threaded into the axle boss with an O-ring seal and required a lot of heat to undo; 41mm x 3.142 = 129mm of contact area per thread which dwarfs even an M10 or M12 bolt and they were fitted with very strong Loctite (IIRC I used JB Weld on reassembly, the 24-hours-to-cure type). Being an adolescent with a number of other rather costly hobbies (ahem) I neglected to match up the O-ring and just rooted through my spares until I found one which looked the same; admittedly a bit twattish but in my defence it was a long time ago, I was very young and we didn't have Simply Bearings etc. back then. Still the forks worked and were oil tight afterwards so all's well that ends well I guess

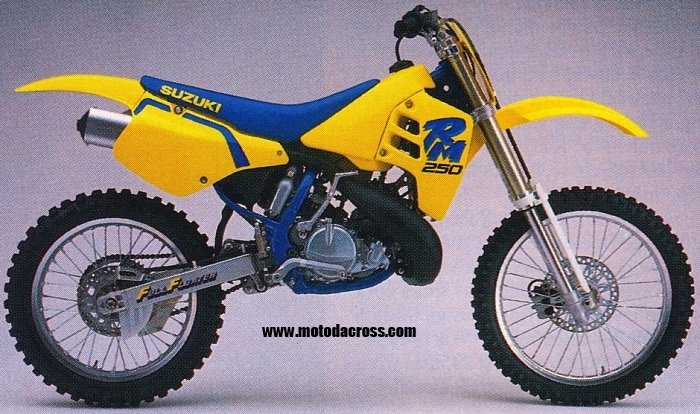

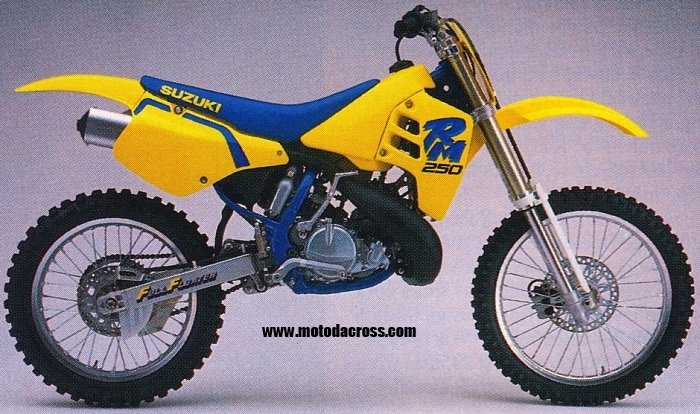

It gave me some ideas though; theoretically you could get something like a 1990 RM250 with the same size USD fork stanchions and give it a twin disc front end with GSX-R axle bosses, 4-pot calipers, XS650 hub, dustbin lid-sized rotors, 17" rim etc. for the ultimate long-travel Supermoto front end. At which point you might like to install an RG500 engine to get your money's worth from the front brake.

Are the forks on your TZR Paoli? If so I think the stanchions would still be threaded into the axle bosses TBH as it's probably just the most convenient way to attach a steel tube to an alloy casting and achieve a sealed joint.

-

@SpookDog In the 90s I replaced a USD fork stanchion on a GSX-R400 GK76A with 41mm Kayaba forks. They were threaded into the axle boss with an O-ring seal and required a lot of heat to undo; 41mm x 3.142 = 129mm of contact area per thread which dwarfs even an M10 or M12 bolt and they were fitted with very strong Loctite (IIRC I used JB Weld on reassembly, the 24-hours-to-cure type). Being an adolescent with a number of other rather costly hobbies (ahem) I neglected to match up the O-ring and just rooted through my spares until I found one which looked the same; admittedly a bit twattish but in my defence it was a long time ago, I was very young and we didn't have Simply Bearings etc. back then. Still the forks worked and were oil tight afterwards so all's well that ends well I guess

It gave me some ideas though; theoretically you could get something like a 1990 RM250 with the same size USD fork stanchions and give it a twin disc front end with GSX-R axle bosses, 4-pot calipers, XS650 hub, dustbin lid-sized rotors, 17" rim etc. for the ultimate long-travel Supermoto front end. At which point you might like to install an RG500 engine to get your money's worth from the front brake.

Are the forks on your TZR Paoli? If so I think the stanchions would still be threaded into the axle bosses TBH as it's probably just the most convenient way to attach a steel tube to an alloy casting and achieve a sealed joint.

Damn, I still have expensive hobbits!

I did a quick search and the forks you can unscrew have a fixing/grub screw on the inside of the fork bottoms. Mine has that. It’s not the Paoli fork. It’s a steel upper (not gold ally) and it has the fitting for a calliper on the throttle side leg bottom as well, as does the wheel for a disc! Tzr250 3xv right callipers are like unicorns sh1+ though, but there are 4pot Triumph ones that apparently fit for a good price.

I digress! It does mean I can strip them if I can find stachions (39mm) for a reasonable price. £180 is all I’ve found so far…Cheers guys!…

-

Damn, I still have expensive hobbits!

I did a quick search and the forks you can unscrew have a fixing/grub screw on the inside of the fork bottoms. Mine has that. It’s not the Paoli fork. It’s a steel upper (not gold ally) and it has the fitting for a calliper on the throttle side leg bottom as well, as does the wheel for a disc! Tzr250 3xv right callipers are like unicorns sh1+ though, but there are 4pot Triumph ones that apparently fit for a good price.

I digress! It does mean I can strip them if I can find stachions (39mm) for a reasonable price. £180 is all I’ve found so far…Cheers guys!…

P.S. I’m embarrassed to admit, but I’ve used JB weld chemical metal to fill in pits on stantions before in my yoof! It worked for as long as the bike did

which wasn’t too long. £150 for a CDI was a lot of money in 88!

which wasn’t too long. £150 for a CDI was a lot of money in 88!  …

…

It was definitely more than the bike was worth! 🫤 -

@OllieDTR I use Flickr to post up pics on here. Choose one out of your photostream, click the download icon and choose "view all sizes", then right click the picture and choose "open image in new tab". Copy and paste the URL from that webpage into the image link on here (7th from the left). Front end looks good

-

Damn, I still have expensive hobbits!

I did a quick search and the forks you can unscrew have a fixing/grub screw on the inside of the fork bottoms. Mine has that. It’s not the Paoli fork. It’s a steel upper (not gold ally) and it has the fitting for a calliper on the throttle side leg bottom as well, as does the wheel for a disc! Tzr250 3xv right callipers are like unicorns sh1+ though, but there are 4pot Triumph ones that apparently fit for a good price.

I digress! It does mean I can strip them if I can find stachions (39mm) for a reasonable price. £180 is all I’ve found so far…Cheers guys!…

@SpookDog There are places that can re-chrome fork stanchions, only a few in the UK as they're hard chrome which I think has to be ground back to the correct OD unlike the more common soft chrome which is what is used on grab rails etc. and not up to being a bearing surface (and apparently you can't use hard chrome for decorative items either).

I wonder if you could run R1-type blue spot calipers? They seem to fit anywhere on Yamahas those older type Sumitomo calipers were used originally, lots of people retrofit them to TZR/TDR250s etc. I've never done anything with them but @Stevie-Wonder rebuilt a set on an FZS600 Fazer and might be able to advise further? Probably easier to find secondhand and would make for one seriously trick TZR125R