What was I thinking!…

-

I have never needed it, a slight tap with a rubber mallet sorts it out.

But you should be able to apply some pressure to the crank end to ease off the cases.

I’ve seen some casings that have been chiselled apart! I’ve been guilty of the same in my yoof, I don’t doubt 🥴

I put a little bit of pressure on it then tapped the cases with a hubber rammer, it popped apart lovely. Only wish I could of left both bearings in the casings. I did try heating the tight bearing to get it to let go of the crank. No joy tho’

I just need to get a ‘clamshell’ bearing puller now. No more levering away with flathead screwdrivers!…

I just need to get a ‘clamshell’ bearing puller now. No more levering away with flathead screwdrivers!…I really need to start prioritising the two bikes now. I’ve got everything to rebuild a tight, righteous motor for the Dtr, but I want to strip, dip & coat the frame, ect. As well as making a new loom. I really need to get the Tzr running and throw an mot at it to make a daily while I work out the Dtr. I think I’m gonna have to keep limping along the leperous motor that’s in the Dtr some more. It hasn’t stranded me yet in over 25K smiles

…

… -

I’ve seen some casings that have been chiselled apart! I’ve been guilty of the same in my yoof, I don’t doubt 🥴

I put a little bit of pressure on it then tapped the cases with a hubber rammer, it popped apart lovely. Only wish I could of left both bearings in the casings. I did try heating the tight bearing to get it to let go of the crank. No joy tho’

I just need to get a ‘clamshell’ bearing puller now. No more levering away with flathead screwdrivers!…

I just need to get a ‘clamshell’ bearing puller now. No more levering away with flathead screwdrivers!…I really need to start prioritising the two bikes now. I’ve got everything to rebuild a tight, righteous motor for the Dtr, but I want to strip, dip & coat the frame, ect. As well as making a new loom. I really need to get the Tzr running and throw an mot at it to make a daily while I work out the Dtr. I think I’m gonna have to keep limping along the leperous motor that’s in the Dtr some more. It hasn’t stranded me yet in over 25K smiles

…

… -

Anybody know about upside down fork stantion replacement? Can the aluminium bottoms be separated from the chromed steel tubes? Or are they fixed? Cheers…

-

Anybody know about upside down fork stantion replacement? Can the aluminium bottoms be separated from the chromed steel tubes? Or are they fixed? Cheers…

@SpookDog In the 90s I replaced a USD fork stanchion on a GSX-R400 GK76A with 41mm Kayaba forks. They were threaded into the axle boss with an O-ring seal and required a lot of heat to undo; 41mm x 3.142 = 129mm of contact area per thread which dwarfs even an M10 or M12 bolt and they were fitted with very strong Loctite (IIRC I used JB Weld on reassembly, the 24-hours-to-cure type). Being an adolescent with a number of other rather costly hobbies (ahem) I neglected to match up the O-ring and just rooted through my spares until I found one which looked the same; admittedly a bit twattish but in my defence it was a long time ago, I was very young and we didn't have Simply Bearings etc. back then. Still the forks worked and were oil tight afterwards so all's well that ends well I guess

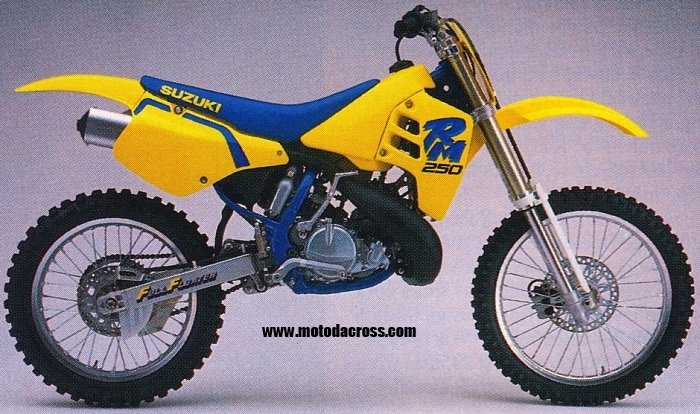

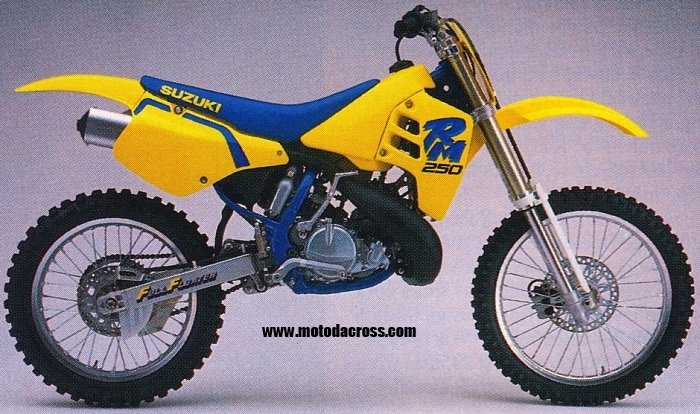

It gave me some ideas though; theoretically you could get something like a 1990 RM250 with the same size USD fork stanchions and give it a twin disc front end with GSX-R axle bosses, 4-pot calipers, XS650 hub, dustbin lid-sized rotors, 17" rim etc. for the ultimate long-travel Supermoto front end. At which point you might like to install an RG500 engine to get your money's worth from the front brake.

Are the forks on your TZR Paoli? If so I think the stanchions would still be threaded into the axle bosses TBH as it's probably just the most convenient way to attach a steel tube to an alloy casting and achieve a sealed joint.

-

@SpookDog In the 90s I replaced a USD fork stanchion on a GSX-R400 GK76A with 41mm Kayaba forks. They were threaded into the axle boss with an O-ring seal and required a lot of heat to undo; 41mm x 3.142 = 129mm of contact area per thread which dwarfs even an M10 or M12 bolt and they were fitted with very strong Loctite (IIRC I used JB Weld on reassembly, the 24-hours-to-cure type). Being an adolescent with a number of other rather costly hobbies (ahem) I neglected to match up the O-ring and just rooted through my spares until I found one which looked the same; admittedly a bit twattish but in my defence it was a long time ago, I was very young and we didn't have Simply Bearings etc. back then. Still the forks worked and were oil tight afterwards so all's well that ends well I guess

It gave me some ideas though; theoretically you could get something like a 1990 RM250 with the same size USD fork stanchions and give it a twin disc front end with GSX-R axle bosses, 4-pot calipers, XS650 hub, dustbin lid-sized rotors, 17" rim etc. for the ultimate long-travel Supermoto front end. At which point you might like to install an RG500 engine to get your money's worth from the front brake.

Are the forks on your TZR Paoli? If so I think the stanchions would still be threaded into the axle bosses TBH as it's probably just the most convenient way to attach a steel tube to an alloy casting and achieve a sealed joint.

Damn, I still have expensive hobbits!

I did a quick search and the forks you can unscrew have a fixing/grub screw on the inside of the fork bottoms. Mine has that. It’s not the Paoli fork. It’s a steel upper (not gold ally) and it has the fitting for a calliper on the throttle side leg bottom as well, as does the wheel for a disc! Tzr250 3xv right callipers are like unicorns sh1+ though, but there are 4pot Triumph ones that apparently fit for a good price.

I digress! It does mean I can strip them if I can find stachions (39mm) for a reasonable price. £180 is all I’ve found so far…Cheers guys!…

-

Damn, I still have expensive hobbits!

I did a quick search and the forks you can unscrew have a fixing/grub screw on the inside of the fork bottoms. Mine has that. It’s not the Paoli fork. It’s a steel upper (not gold ally) and it has the fitting for a calliper on the throttle side leg bottom as well, as does the wheel for a disc! Tzr250 3xv right callipers are like unicorns sh1+ though, but there are 4pot Triumph ones that apparently fit for a good price.

I digress! It does mean I can strip them if I can find stachions (39mm) for a reasonable price. £180 is all I’ve found so far…Cheers guys!…

P.S. I’m embarrassed to admit, but I’ve used JB weld chemical metal to fill in pits on stantions before in my yoof! It worked for as long as the bike did

which wasn’t too long. £150 for a CDI was a lot of money in 88!

which wasn’t too long. £150 for a CDI was a lot of money in 88!  …

…

It was definitely more than the bike was worth! 🫤 -

@OllieDTR I use Flickr to post up pics on here. Choose one out of your photostream, click the download icon and choose "view all sizes", then right click the picture and choose "open image in new tab". Copy and paste the URL from that webpage into the image link on here (7th from the left). Front end looks good

-

Damn, I still have expensive hobbits!

I did a quick search and the forks you can unscrew have a fixing/grub screw on the inside of the fork bottoms. Mine has that. It’s not the Paoli fork. It’s a steel upper (not gold ally) and it has the fitting for a calliper on the throttle side leg bottom as well, as does the wheel for a disc! Tzr250 3xv right callipers are like unicorns sh1+ though, but there are 4pot Triumph ones that apparently fit for a good price.

I digress! It does mean I can strip them if I can find stachions (39mm) for a reasonable price. £180 is all I’ve found so far…Cheers guys!…

@SpookDog There are places that can re-chrome fork stanchions, only a few in the UK as they're hard chrome which I think has to be ground back to the correct OD unlike the more common soft chrome which is what is used on grab rails etc. and not up to being a bearing surface (and apparently you can't use hard chrome for decorative items either).

I wonder if you could run R1-type blue spot calipers? They seem to fit anywhere on Yamahas those older type Sumitomo calipers were used originally, lots of people retrofit them to TZR/TDR250s etc. I've never done anything with them but @Stevie-Wonder rebuilt a set on an FZS600 Fazer and might be able to advise further? Probably easier to find secondhand and would make for one seriously trick TZR125R

-

@OllieDTR I use Flickr to post up pics on here. Choose one out of your photostream, click the download icon and choose "view all sizes", then right click the picture and choose "open image in new tab". Copy and paste the URL from that webpage into the image link on here (7th from the left). Front end looks good

-

-

@SpookDog There are places that can re-chrome fork stanchions, only a few in the UK as they're hard chrome which I think has to be ground back to the correct OD unlike the more common soft chrome which is what is used on grab rails etc. and not up to being a bearing surface (and apparently you can't use hard chrome for decorative items either).

I wonder if you could run R1-type blue spot calipers? They seem to fit anywhere on Yamahas those older type Sumitomo calipers were used originally, lots of people retrofit them to TZR/TDR250s etc. I've never done anything with them but @Stevie-Wonder rebuilt a set on an FZS600 Fazer and might be able to advise further? Probably easier to find secondhand and would make for one seriously trick TZR125R

Cheers bud, I’ll look into them! The disc are east enough to find. Imagine the confidence two 11inch floating discs & four pots will give! No modding, just replace the master and bolt it all on!

…

…I might know of an old belgarda going that a lad wants £500 for. I haven’t seen it but you can imagine it’s been well used

…

…

Edit:

Looks like it’s more expensive to hard chrome than to replace with Paolo stanchions… -

Cheers bud, I’ll look into them! The disc are east enough to find. Imagine the confidence two 11inch floating discs & four pots will give! No modding, just replace the master and bolt it all on!

…

…I might know of an old belgarda going that a lad wants £500 for. I haven’t seen it but you can imagine it’s been well used

…

…

Edit:

Looks like it’s more expensive to hard chrome than to replace with Paolo stanchions…If anyone can find a ‘how to’ vid or manual, or anything about dismantling USD 4hw non adjustable forks, can you please let me know. I’m 99% confidant in my doing it on the fly, but I’d rather learn from someone else’s mistakes

…

…

I am lazy but I have looked… -

If anyone can find a ‘how to’ vid or manual, or anything about dismantling USD 4hw non adjustable forks, can you please let me know. I’m 99% confidant in my doing it on the fly, but I’d rather learn from someone else’s mistakes

…

…

I am lazy but I have looked… -

I’m having real problems finding the guide bush size on the 1993 Tzr125rr 4HW

Both of the bush sizes would be cool if anyone can help! Please…

-

I’ve looked high & low. I’m gonna have to sand down the fuxed scraped ones and put them back in. Brooks suspension don’t seem to offer them by size anymore. Not that my measurements were to the tenth of a mm!…

@SpookDog Have you tried Simply Bearings? Those bushes are a pretty common engineering component after all, if you know the dimensions of the stanchion and where they fit, they or another bearing supplier can probably help.

-

@SpookDog Have you tried Simply Bearings? Those bushes are a pretty common engineering component after all, if you know the dimensions of the stanchion and where they fit, they or another bearing supplier can probably help.

No I’ve not tried them yet. I’m don’t know what the dimensions are, I can’t find them. I don’t have the tools to measure the existing bushes properly, to the 10th of a MM. i learnt that it matters the hard way last time!

…

…The fork stanchions are 39mm, the depth of the bush is 20mm, the outer edge looks to be 42mm. I’m guessing the thickness of the bush is a bit les than 1.5 mm, but don’t know for sure and can’t find anything similar…

Edit: nope, can’t even find any bushes on their site

…

…