So Close!...

-

Initial test ride is promising. Cruising at 25-30 without the previous issues. No tap-rattle and humming from the top end! Won’t know for sure till I take it on a 20-30 mile run though…

Put a spot of chemical metal over the leak for temporary/now…

Just noticed something potentially interesting. The red 2T oil warning light flickers at just about 4K rpm, at the same time I get a little ‘snaggle’ in the revs. Feels a bit like when you rev the engine when it’s cold. Just hesitating slightly. I’d of thought that when the flywheel is spinning at that speed the electrical output would be constant, whether the engine is firing or not? So it’s be something that interrupts the ignition and oil light simultaneously. No?…

Where is the diode located?…

-

Just noticed something potentially interesting. The red 2T oil warning light flickers at just about 4K rpm, at the same time I get a little ‘snaggle’ in the revs. Feels a bit like when you rev the engine when it’s cold. Just hesitating slightly. I’d of thought that when the flywheel is spinning at that speed the electrical output would be constant, whether the engine is firing or not? So it’s be something that interrupts the ignition and oil light simultaneously. No?…

Where is the diode located?…

@SpookDog The diode is shown on all wiring diagrams as connecting the black/red oil light wire to the sky blue neutral light wire between the oil level sender unit and the 3-pin connector, i.e on the sub-loom for the sender unit. The oil light bulb wires are brown (main feed from the switch) and black/red (which goes to earth either when the sender unit operates from low 2T oil or via the neutral switch through the diode) so ordinarily it illuminates via either of these things happening.

Are you certain the neutral light isn't flickering at the same time? If it definitely isn't, you can rule out the sky blue wire tracking to earth (and therefore the diode) which means it must be the black/red wire doing this somewhere. Someone mentioned your ignition coil is fitted the wrong way round in an earlier post, and this area around the servo/coil/throttle cable is a right rat's nest of wiring on all DTRs (including the oil level sender wire) so maybe try swapping this round (i.e so the HT lead is at the bottom and the LT orange wire is at the top). IIRC only one of the mounts on the stock coil is actually an earth, this is the lower one when the coil is fitted correctly so this is where the earth terminal from the loom should attach (and did you remember to scrape the paint off the lower coil mount for a really good main earth? Lots of people fall down this hole when respraying a frame).

This is all I can think of but it's too much of a coincidence if the HT lead is routed differently potentially being forced against the loom with the fuel tank fitted.

I once had a misfire on a VW Golf, my £35 eBay code reader indicated a bad crank sensor so I bought one and fitted it which cured the problem. It was quite difficult to get to so I didn't actually look at the sensor until I got underneath the car to fit the new one, and where the wires passed between the engine block and oil filter housing the insulation had worn through from vibration. Before doing the job, the car always started and ran well apart from a misfire which always occurred at the same engine speed so I think the signal from the crank sensor was just tracking to earth and confusing the ECU.

-

Just noticed something potentially interesting. The red 2T oil warning light flickers at just about 4K rpm, at the same time I get a little ‘snaggle’ in the revs. Feels a bit like when you rev the engine when it’s cold. Just hesitating slightly. I’d of thought that when the flywheel is spinning at that speed the electrical output would be constant, whether the engine is firing or not? So it’s be something that interrupts the ignition and oil light simultaneously. No?…

Where is the diode located?…

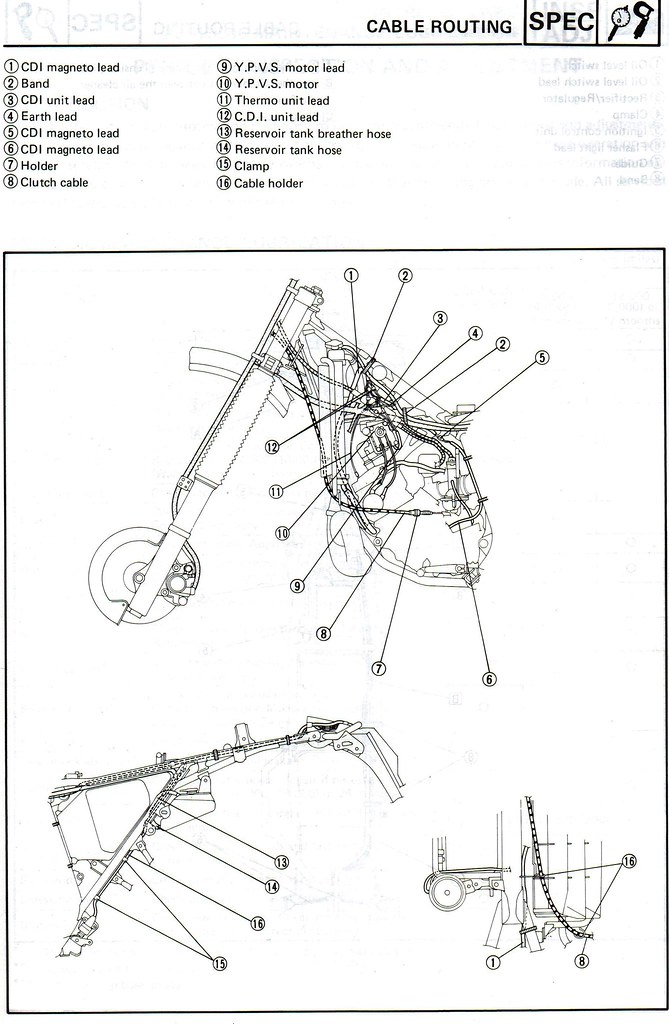

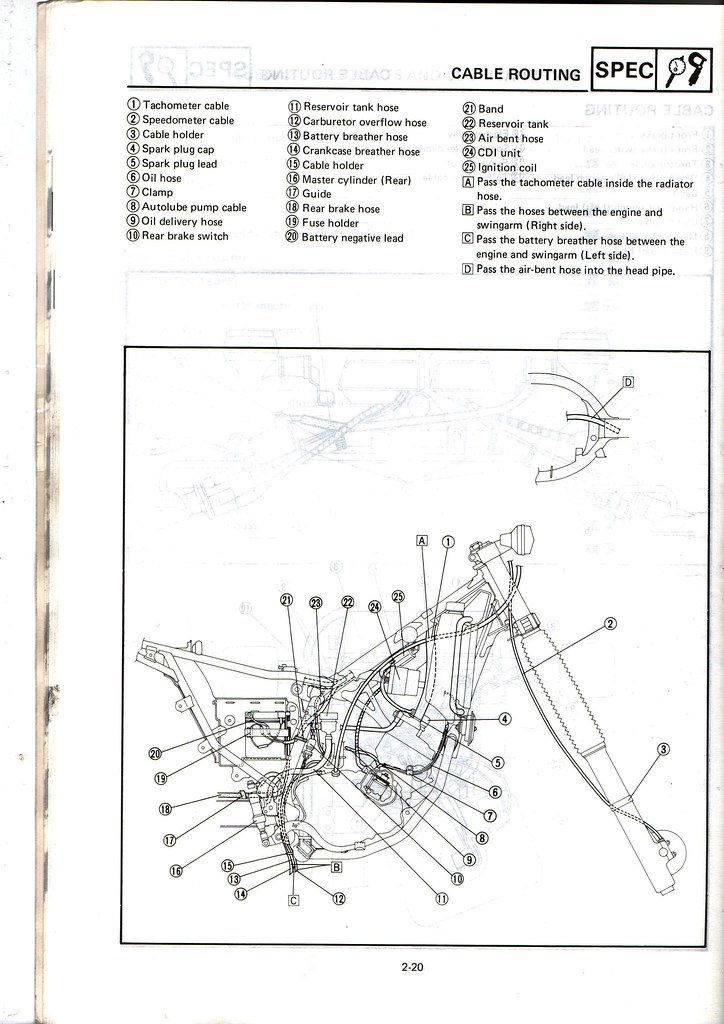

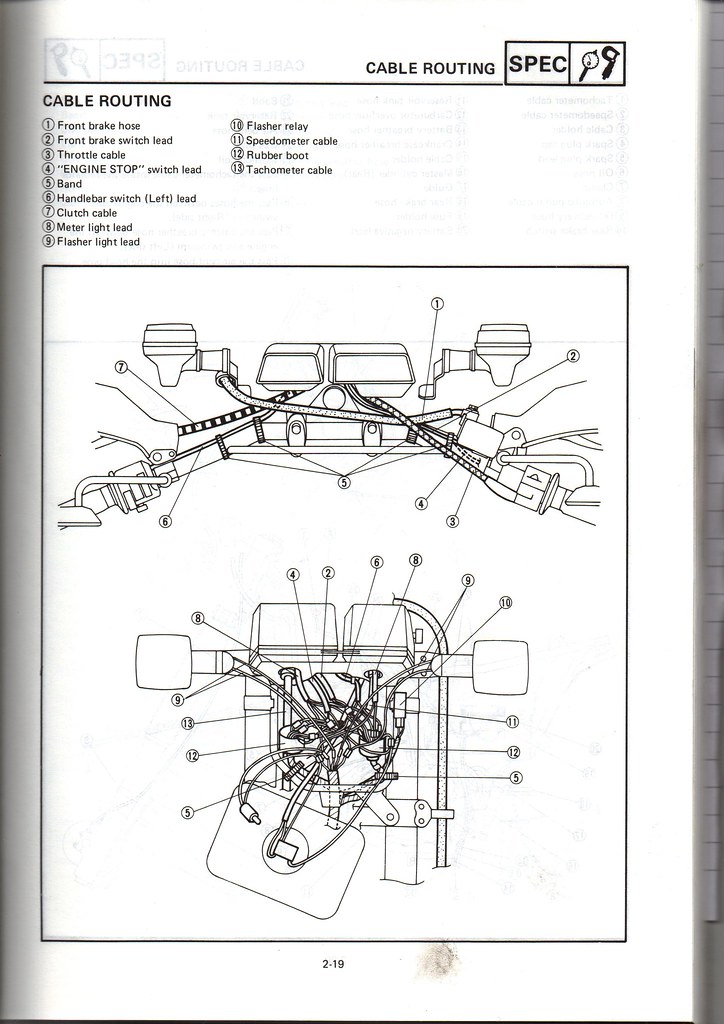

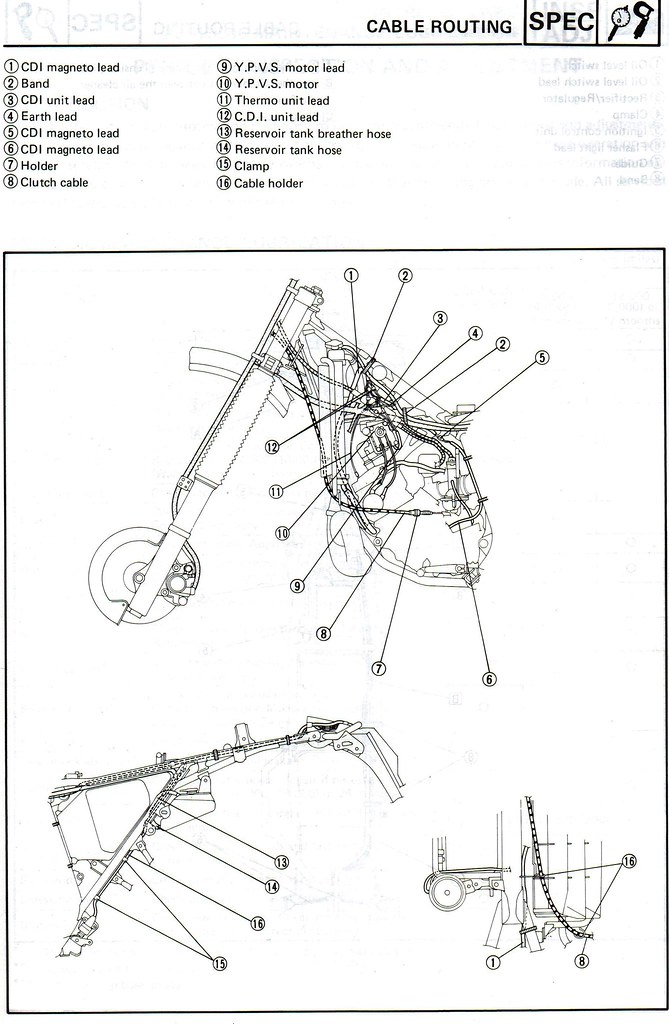

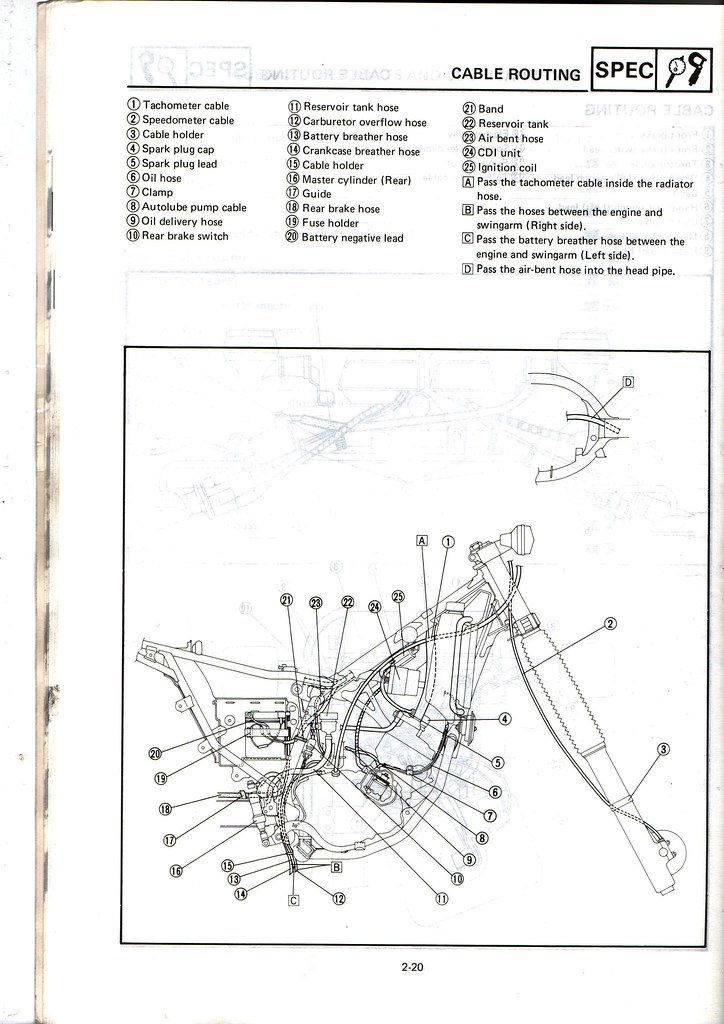

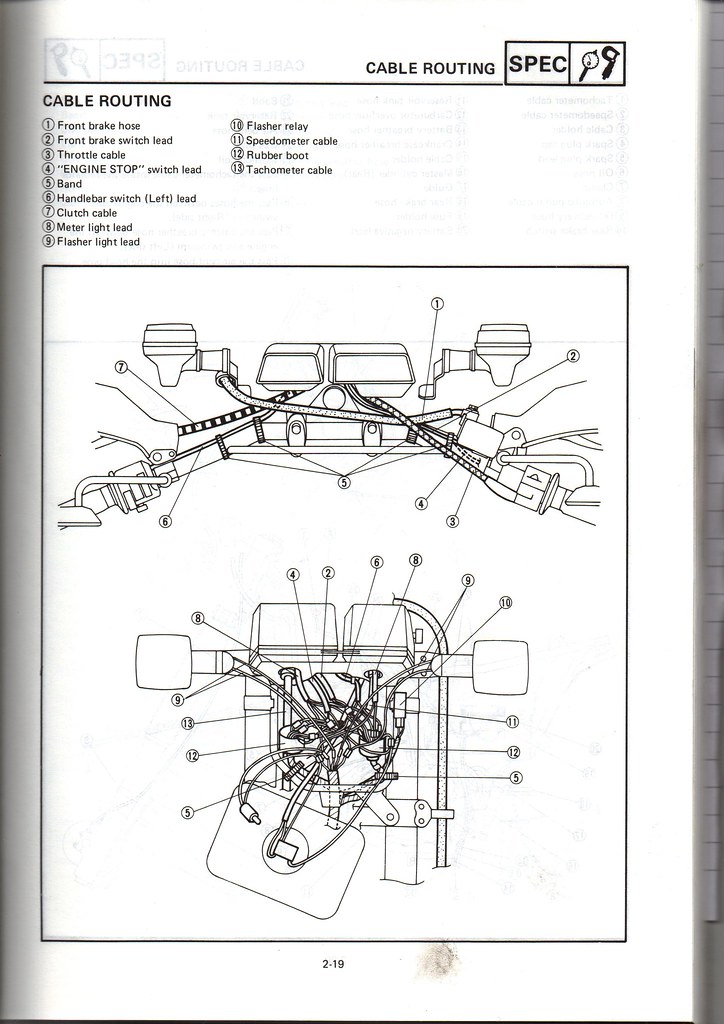

@SpookDog Just been chewing this over a bit more and the orange wire from the CDI energises the low-tension side of the coil (which then goes to earth). Your wiring loom is also on the opposite side of the frame to where it should be which means the CDI wires and the main loom are being forced together, potentially allowing the pulse from the CDI to track to the oil light wire at certain engine speeds (30-year-old wiring and all that). So I'd definitely be having a good poke around in this general area, and looking again at the cable routing images I posted up on here a few weeks ago.

TBH although I understand wiring diagrams, due to my liking for keeping cable routing stock and well coated with WD40 I don't have a huge amount of experience at actually solving electrical problems but if your wiring is incorrectly routed I'd definitely be starting here.

-

Invaluable as always @HOTSHOT-III

-

The only thing different about the red oil light is that it runs through/is controlled by the CDI unit, no?

Oil light: flickers at 4K

The dial illumination lights: doesn’t flicker

Neutral light: doesn’t flickerWhen the oil light flicked it is definitely ‘in tune’ with the ignition.

Another weird thing is that the neutral light flickers on in 6th gear…I’ve got connectors butchered by previous owners on the pulse/pickup as well as the CDI-loom…

I have a spare CDI (3nc-00)

Pulse pickup.

Ignition coil & charging coil.

Ht coil.I’m going to start with the pickup because it’s got the oldest bodge wiring. Then CDI…

@HOTSHOT-III

Cheers bud, I don’t know what I’d do without your help. Once I get this issue sorted the bikes going to be perfect…PS Question! Which side does the coil earth bolt to? Orange wire side, or the other?…

-

The only thing different about the red oil light is that it runs through/is controlled by the CDI unit, no?

Oil light: flickers at 4K

The dial illumination lights: doesn’t flicker

Neutral light: doesn’t flickerWhen the oil light flicked it is definitely ‘in tune’ with the ignition.

Another weird thing is that the neutral light flickers on in 6th gear…I’ve got connectors butchered by previous owners on the pulse/pickup as well as the CDI-loom…

I have a spare CDI (3nc-00)

Pulse pickup.

Ignition coil & charging coil.

Ht coil.I’m going to start with the pickup because it’s got the oldest bodge wiring. Then CDI…

@HOTSHOT-III

Cheers bud, I don’t know what I’d do without your help. Once I get this issue sorted the bikes going to be perfect…PS Question! Which side does the coil earth bolt to? Orange wire side, or the other?…

I don’t get how both the neutral and oil lights run off of the battery, but only one is flickering. I’ve changed out both bulbs and cleaned up the connections. I’m going to swap out the neutral switch before I do the next test…

Also when the ignition ‘snaggles’ it doesn’t affect the headlight or dial lights. So I don’t think it’s a common earth thing…

PS I sussed out that the earth bolts to the opposite side of the orange wire, which is where it is…

Edit: I used to have a little RSX100 30 years ago. I can remember the way the revs picked up so fast and crisp! I’ve only ever had that happen once , for a short while, with my Dtr, when I put a proper 0.25 pilot jet in. The bike did a little wheelie pulling away normally. Like a frisky pup!

I really want to sort this bike back to that state…

I really want to sort this bike back to that state… -

I don’t get how both the neutral and oil lights run off of the battery, but only one is flickering. I’ve changed out both bulbs and cleaned up the connections. I’m going to swap out the neutral switch before I do the next test…

Also when the ignition ‘snaggles’ it doesn’t affect the headlight or dial lights. So I don’t think it’s a common earth thing…

PS I sussed out that the earth bolts to the opposite side of the orange wire, which is where it is…

Edit: I used to have a little RSX100 30 years ago. I can remember the way the revs picked up so fast and crisp! I’ve only ever had that happen once , for a short while, with my Dtr, when I put a proper 0.25 pilot jet in. The bike did a little wheelie pulling away normally. Like a frisky pup!

I really want to sort this bike back to that state…

I really want to sort this bike back to that state… -

The pickup has 3 separate joins in it, as well as the rubber entry point into the stator being a ‘break point’. I’m going to start my journey here

OK. Now it gets weird!…

I just checked my power valve and it’s been opening at 3.5~4K rpm (just @ where I’ve had the ‘snaggle’)

The wire coming from my 3 wire servo is black & white. So I’ve been connecting it to the black & white wire coming from the CDI.Just for shits and giggles: I connected it to the black & yellow wire coming from the CDI (because I remembered being told the signal wire was black/yellow) Guess what? Power valve is opening at 5~6k rpm.

The kill switch works whichever way I have them. As does the power valve, but at different rpm’s.

Question is: What RPM is the power valve supposed to open at?!! …

-

@SpookDog at 6k or 6.5k if I remember correctly,also I think it's black and yellow at my PV but there's some time since I 've seen it.

Yeah, I’ve been told that the PV signal wire is black and yellow. I didn’t look that closely for colour when I was putting the loom, CDI and stuff all together.

The wire from my servo is black & white striped. So I’ve been wiring it to the bikes kill switch curcuit. Fux knows how it was still working and kicking in the power valve when revving the engine. I never checked the RPM speed, just that the valve was operating when revved…So tomorrow I go for a test ride with it connected yellow to white and opening at 6k~ish…

It’s strange that the kill switch curcuit on the loom is black&yellow, not white. It does look like the wire may of been replaced before, now with hindsight, I’ve scrutinised it!…

—————————————

The power valve has been opening at just below 4K RPM which is about 1/8 throttle. If I’m right, this would impact the pilot/throttle-valve curcuit causing it to ‘snaggle’ maybe because of the change of scavenging?

Remember, I’m trying to suss this out from a position of total ignorance! Any thoughts or feedback would be appreciated…PS When I put my chain back on after spraying the frame, ect. I think I may of put it on upside down (or inside out). It’s been getting tighter day by day. I’ve loosened it once but it’s tight again. No slippage at the rear spindle/adjusters. I thought maybe the salt had gotten to it because I’ve done fux all miles in the last month or so (120) Thoughts again?…

-

Yeah, I’ve been told that the PV signal wire is black and yellow. I didn’t look that closely for colour when I was putting the loom, CDI and stuff all together.

The wire from my servo is black & white striped. So I’ve been wiring it to the bikes kill switch curcuit. Fux knows how it was still working and kicking in the power valve when revving the engine. I never checked the RPM speed, just that the valve was operating when revved…So tomorrow I go for a test ride with it connected yellow to white and opening at 6k~ish…

It’s strange that the kill switch curcuit on the loom is black&yellow, not white. It does look like the wire may of been replaced before, now with hindsight, I’ve scrutinised it!…

—————————————

The power valve has been opening at just below 4K RPM which is about 1/8 throttle. If I’m right, this would impact the pilot/throttle-valve curcuit causing it to ‘snaggle’ maybe because of the change of scavenging?

Remember, I’m trying to suss this out from a position of total ignorance! Any thoughts or feedback would be appreciated…PS When I put my chain back on after spraying the frame, ect. I think I may of put it on upside down (or inside out). It’s been getting tighter day by day. I’ve loosened it once but it’s tight again. No slippage at the rear spindle/adjusters. I thought maybe the salt had gotten to it because I’ve done fux all miles in the last month or so (120) Thoughts again?…

-

So much better! There’s a little bit of cleaning up to do, from where I was adjusting the airscrew to try and fix the issues before…

I’m going to wait for a decent wind free & dry day to do that though… -

@SpookDog Just been chewing this over a bit more and the orange wire from the CDI energises the low-tension side of the coil (which then goes to earth). Your wiring loom is also on the opposite side of the frame to where it should be which means the CDI wires and the main loom are being forced together, potentially allowing the pulse from the CDI to track to the oil light wire at certain engine speeds (30-year-old wiring and all that). So I'd definitely be having a good poke around in this general area, and looking again at the cable routing images I posted up on here a few weeks ago.

TBH although I understand wiring diagrams, due to my liking for keeping cable routing stock and well coated with WD40 I don't have a huge amount of experience at actually solving electrical problems but if your wiring is incorrectly routed I'd definitely be starting here.

Just a quick thank yous. My radiator level has been sweet since installing the banjo union U

…

…——————————-

Bike is running @ 90%, best yet but still a little snaggle at low rpm cruising. Leaning out the airscrew has improved but not cured it.

Just replaced the reed valve and re-installed the plastic ‘pickup’ tube on the pilot jet. Just going dotty for T and crossing my I’s at the moment. Will test ride tomorrow weather permitting.

If it’s still the same I’ll change over the CDI unit, Dog only knows what damage having the yellow & white stripe wires crossed has caused?!… -

Just a quick thank yous. My radiator level has been sweet since installing the banjo union U

…

…——————————-

Bike is running @ 90%, best yet but still a little snaggle at low rpm cruising. Leaning out the airscrew has improved but not cured it.

Just replaced the reed valve and re-installed the plastic ‘pickup’ tube on the pilot jet. Just going dotty for T and crossing my I’s at the moment. Will test ride tomorrow weather permitting.

If it’s still the same I’ll change over the CDI unit, Dog only knows what damage having the yellow & white stripe wires crossed has caused?!…@SpookDog All sounds good!

If the bike still runs I doubt you've done any damage to the CDI by crossing those wires, usually CDI units either work or they don't. Interesting it did still work though; the black/yellow wire tells the little on-board computer inside the 3-wire servo the engine speed (like the crank sensor on a car) and the black/white wire stops the plug sparking by earthing the CDI when you flick the kill switch or turn off the ignition, so I guess if you hooked either of those wires from the CDI up to some test equipment like an oscilloscope, you'd probably get some quite similar results.

Keep us posted for any improvements!

-

@SpookDog All sounds good!

If the bike still runs I doubt you've done any damage to the CDI by crossing those wires, usually CDI units either work or they don't. Interesting it did still work though; the black/yellow wire tells the little on-board computer inside the 3-wire servo the engine speed (like the crank sensor on a car) and the black/white wire stops the plug sparking by earthing the CDI when you flick the kill switch or turn off the ignition, so I guess if you hooked either of those wires from the CDI up to some test equipment like an oscilloscope, you'd probably get some quite similar results.

Keep us posted for any improvements!

Thing that blew my mind was that it opened at around 4K! Why would the resistance (I’m guessing) change on the ‘to earth’ kill curcuit?! Also the chances of getting a 3 wire servo with a black/white stripe? As well as the black/white wire from the loom being changed?! That’s some fuxin cosmic improbability going on. Whiskey Tango Foxtrot is going on with My Life?!…

I’ll take some pics when the light is good enough to show the colours properly…

Couldn’t make this shit up!…

-

Thing that blew my mind was that it opened at around 4K! Why would the resistance (I’m guessing) change on the ‘to earth’ kill curcuit?! Also the chances of getting a 3 wire servo with a black/white stripe? As well as the black/white wire from the loom being changed?! That’s some fuxin cosmic improbability going on. Whiskey Tango Foxtrot is going on with My Life?!…

I’ll take some pics when the light is good enough to show the colours properly…

Couldn’t make this shit up!…

Could it possibly be something as banal as a rotten earth to the coil?

It seems it may be that the opposite side to the orange wires earth point (on the coil!) is more important that it’s connected 100% to the loom, rather than the frame…

There is a join in the earth lead from previous abusers. One of those hard plastic crimp jobs. If I’d thought it was essential I’d of looked and addressed it before now! The wire was dry and crumbly between fingers…

Will know tomorrow when I’m alcohol free, but the motor is spooling up really crisp and fast, and the spark seems a lot stronger. I’ve been wrong before though… -

Could it possibly be something as banal as a rotten earth to the coil?

It seems it may be that the opposite side to the orange wires earth point (on the coil!) is more important that it’s connected 100% to the loom, rather than the frame…

There is a join in the earth lead from previous abusers. One of those hard plastic crimp jobs. If I’d thought it was essential I’d of looked and addressed it before now! The wire was dry and crumbly between fingers…

Will know tomorrow when I’m alcohol free, but the motor is spooling up really crisp and fast, and the spark seems a lot stronger. I’ve been wrong before though… -

Still not there, my spark is healthier looking, but still red-orange. I believe a healthy spark should be blue-white?…

PS earth is NOT that important, it still runs with it disconnected

I tried fitting the 3nc CDI, it only fires once then nothing. It has 3 extra wires on it, blue and sky blue (2pin block connector) and blue/yellow-stripe (maybe white) I’m wondering if they’re to do with the side stand kill curcuit. I think I need to manipulate them to make it spark constantly…

Will the bike start with the side stand down and in neutral? Or does the stand have to be up regardless?…

-

Still not there, my spark is healthier looking, but still red-orange. I believe a healthy spark should be blue-white?…

PS earth is NOT that important, it still runs with it disconnected

@SpookDog said in So Close!...:

Still not there, my spark is healthier looking, but still red-orange. I believe a healthy spark should be blue-white?…

PS earth is NOT that important, it still runs with it disconnected

I think you are slowly slipping into my Gordian knot electrical problem.

-

@SpookDog said in So Close!...:

Still not there, my spark is healthier looking, but still red-orange. I believe a healthy spark should be blue-white?…

PS earth is NOT that important, it still runs with it disconnected

I think you are slowly slipping into my Gordian knot electrical problem.

Yeah, I don’t give up easily though. 35 year old looms with black tarnished copper cores can be challenging! This has only started since I removed, stored and replaced the loom. It’s easy to find an intermittent broken inner if it’s just an indicator or tail light wire that you can wobble around. Wires in the core of the loom are another matter

Have you done anything on your bike lately? I know that the weather is still shitty here most of the time…

You’ll have to update your thread with the current situation when you can. We’ll get them running again like they should…