So Close!...

-

I don’t get how both the neutral and oil lights run off of the battery, but only one is flickering. I’ve changed out both bulbs and cleaned up the connections. I’m going to swap out the neutral switch before I do the next test…

Also when the ignition ‘snaggles’ it doesn’t affect the headlight or dial lights. So I don’t think it’s a common earth thing…

PS I sussed out that the earth bolts to the opposite side of the orange wire, which is where it is…

Edit: I used to have a little RSX100 30 years ago. I can remember the way the revs picked up so fast and crisp! I’ve only ever had that happen once , for a short while, with my Dtr, when I put a proper 0.25 pilot jet in. The bike did a little wheelie pulling away normally. Like a frisky pup!

I really want to sort this bike back to that state…

I really want to sort this bike back to that state… -

The pickup has 3 separate joins in it, as well as the rubber entry point into the stator being a ‘break point’. I’m going to start my journey here

OK. Now it gets weird!…

I just checked my power valve and it’s been opening at 3.5~4K rpm (just @ where I’ve had the ‘snaggle’)

The wire coming from my 3 wire servo is black & white. So I’ve been connecting it to the black & white wire coming from the CDI.Just for shits and giggles: I connected it to the black & yellow wire coming from the CDI (because I remembered being told the signal wire was black/yellow) Guess what? Power valve is opening at 5~6k rpm.

The kill switch works whichever way I have them. As does the power valve, but at different rpm’s.

Question is: What RPM is the power valve supposed to open at?!! …

-

@SpookDog at 6k or 6.5k if I remember correctly,also I think it's black and yellow at my PV but there's some time since I 've seen it.

Yeah, I’ve been told that the PV signal wire is black and yellow. I didn’t look that closely for colour when I was putting the loom, CDI and stuff all together.

The wire from my servo is black & white striped. So I’ve been wiring it to the bikes kill switch curcuit. Fux knows how it was still working and kicking in the power valve when revving the engine. I never checked the RPM speed, just that the valve was operating when revved…So tomorrow I go for a test ride with it connected yellow to white and opening at 6k~ish…

It’s strange that the kill switch curcuit on the loom is black&yellow, not white. It does look like the wire may of been replaced before, now with hindsight, I’ve scrutinised it!…

—————————————

The power valve has been opening at just below 4K RPM which is about 1/8 throttle. If I’m right, this would impact the pilot/throttle-valve curcuit causing it to ‘snaggle’ maybe because of the change of scavenging?

Remember, I’m trying to suss this out from a position of total ignorance! Any thoughts or feedback would be appreciated…PS When I put my chain back on after spraying the frame, ect. I think I may of put it on upside down (or inside out). It’s been getting tighter day by day. I’ve loosened it once but it’s tight again. No slippage at the rear spindle/adjusters. I thought maybe the salt had gotten to it because I’ve done fux all miles in the last month or so (120) Thoughts again?…

-

Yeah, I’ve been told that the PV signal wire is black and yellow. I didn’t look that closely for colour when I was putting the loom, CDI and stuff all together.

The wire from my servo is black & white striped. So I’ve been wiring it to the bikes kill switch curcuit. Fux knows how it was still working and kicking in the power valve when revving the engine. I never checked the RPM speed, just that the valve was operating when revved…So tomorrow I go for a test ride with it connected yellow to white and opening at 6k~ish…

It’s strange that the kill switch curcuit on the loom is black&yellow, not white. It does look like the wire may of been replaced before, now with hindsight, I’ve scrutinised it!…

—————————————

The power valve has been opening at just below 4K RPM which is about 1/8 throttle. If I’m right, this would impact the pilot/throttle-valve curcuit causing it to ‘snaggle’ maybe because of the change of scavenging?

Remember, I’m trying to suss this out from a position of total ignorance! Any thoughts or feedback would be appreciated…PS When I put my chain back on after spraying the frame, ect. I think I may of put it on upside down (or inside out). It’s been getting tighter day by day. I’ve loosened it once but it’s tight again. No slippage at the rear spindle/adjusters. I thought maybe the salt had gotten to it because I’ve done fux all miles in the last month or so (120) Thoughts again?…

-

So much better! There’s a little bit of cleaning up to do, from where I was adjusting the airscrew to try and fix the issues before…

I’m going to wait for a decent wind free & dry day to do that though… -

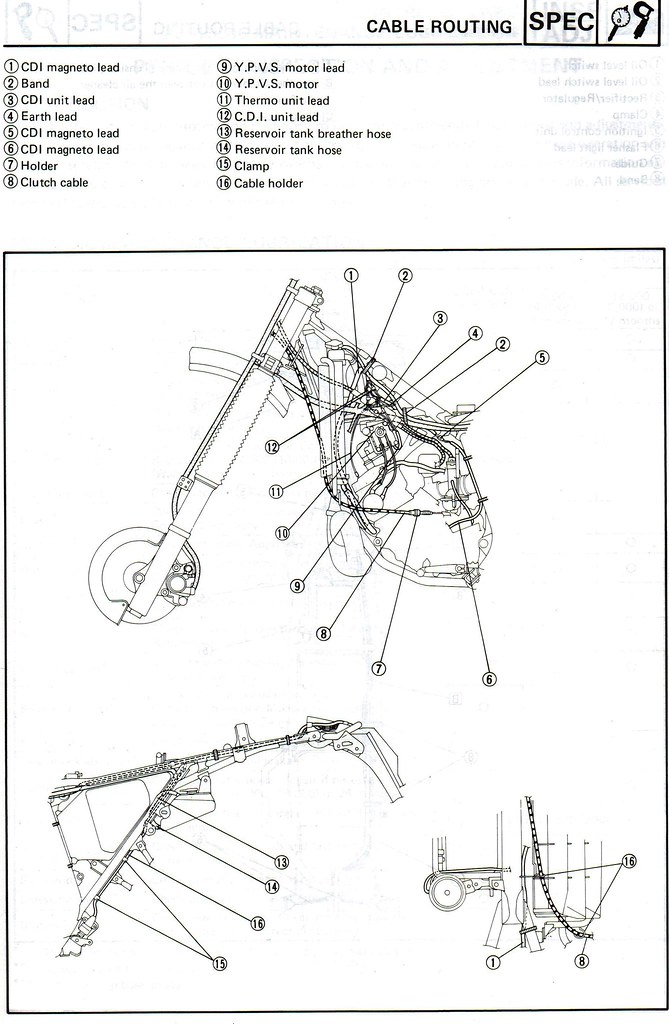

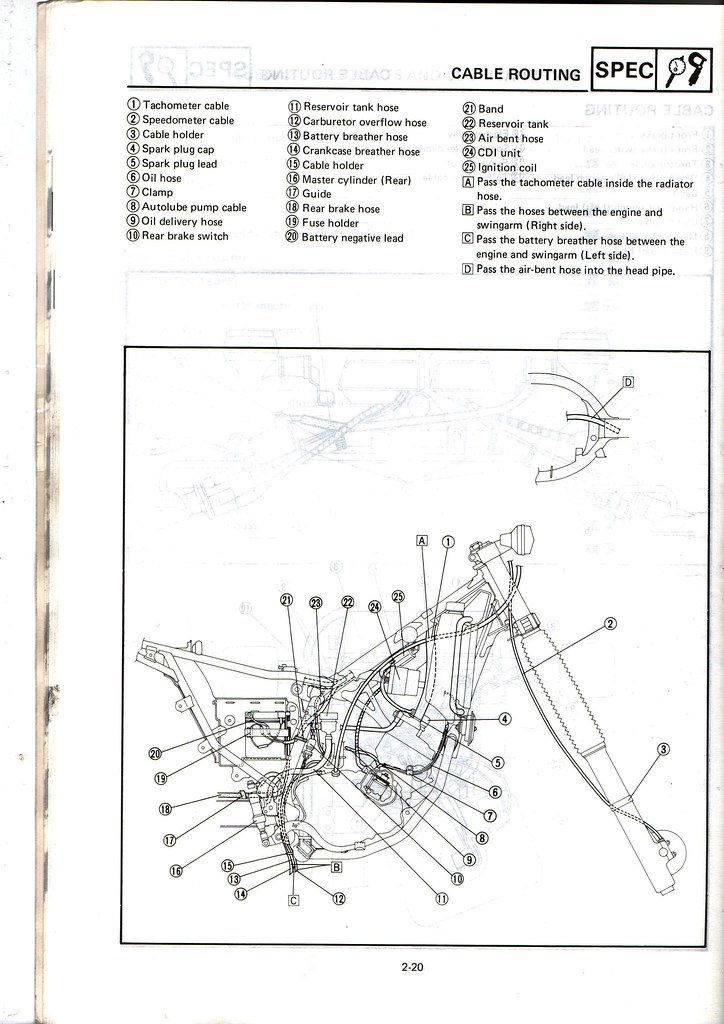

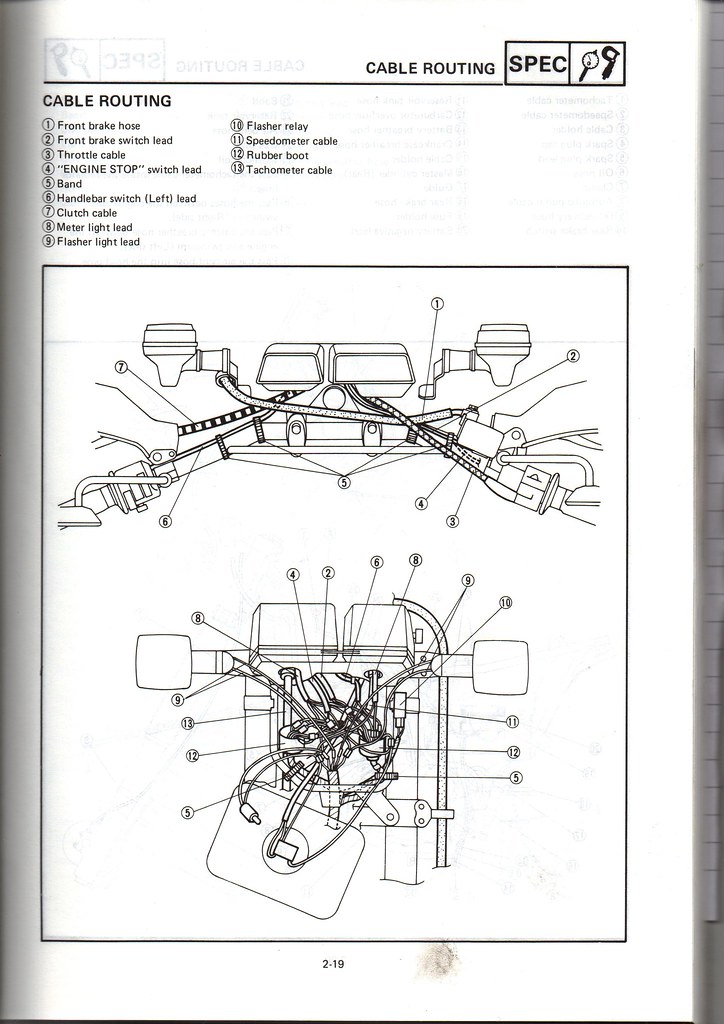

@SpookDog Just been chewing this over a bit more and the orange wire from the CDI energises the low-tension side of the coil (which then goes to earth). Your wiring loom is also on the opposite side of the frame to where it should be which means the CDI wires and the main loom are being forced together, potentially allowing the pulse from the CDI to track to the oil light wire at certain engine speeds (30-year-old wiring and all that). So I'd definitely be having a good poke around in this general area, and looking again at the cable routing images I posted up on here a few weeks ago.

TBH although I understand wiring diagrams, due to my liking for keeping cable routing stock and well coated with WD40 I don't have a huge amount of experience at actually solving electrical problems but if your wiring is incorrectly routed I'd definitely be starting here.

Just a quick thank yous. My radiator level has been sweet since installing the banjo union U

…

…——————————-

Bike is running @ 90%, best yet but still a little snaggle at low rpm cruising. Leaning out the airscrew has improved but not cured it.

Just replaced the reed valve and re-installed the plastic ‘pickup’ tube on the pilot jet. Just going dotty for T and crossing my I’s at the moment. Will test ride tomorrow weather permitting.

If it’s still the same I’ll change over the CDI unit, Dog only knows what damage having the yellow & white stripe wires crossed has caused?!… -

Just a quick thank yous. My radiator level has been sweet since installing the banjo union U

…

…——————————-

Bike is running @ 90%, best yet but still a little snaggle at low rpm cruising. Leaning out the airscrew has improved but not cured it.

Just replaced the reed valve and re-installed the plastic ‘pickup’ tube on the pilot jet. Just going dotty for T and crossing my I’s at the moment. Will test ride tomorrow weather permitting.

If it’s still the same I’ll change over the CDI unit, Dog only knows what damage having the yellow & white stripe wires crossed has caused?!…@SpookDog All sounds good!

If the bike still runs I doubt you've done any damage to the CDI by crossing those wires, usually CDI units either work or they don't. Interesting it did still work though; the black/yellow wire tells the little on-board computer inside the 3-wire servo the engine speed (like the crank sensor on a car) and the black/white wire stops the plug sparking by earthing the CDI when you flick the kill switch or turn off the ignition, so I guess if you hooked either of those wires from the CDI up to some test equipment like an oscilloscope, you'd probably get some quite similar results.

Keep us posted for any improvements!

-

@SpookDog All sounds good!

If the bike still runs I doubt you've done any damage to the CDI by crossing those wires, usually CDI units either work or they don't. Interesting it did still work though; the black/yellow wire tells the little on-board computer inside the 3-wire servo the engine speed (like the crank sensor on a car) and the black/white wire stops the plug sparking by earthing the CDI when you flick the kill switch or turn off the ignition, so I guess if you hooked either of those wires from the CDI up to some test equipment like an oscilloscope, you'd probably get some quite similar results.

Keep us posted for any improvements!

Thing that blew my mind was that it opened at around 4K! Why would the resistance (I’m guessing) change on the ‘to earth’ kill curcuit?! Also the chances of getting a 3 wire servo with a black/white stripe? As well as the black/white wire from the loom being changed?! That’s some fuxin cosmic improbability going on. Whiskey Tango Foxtrot is going on with My Life?!…

I’ll take some pics when the light is good enough to show the colours properly…

Couldn’t make this shit up!…

-

Thing that blew my mind was that it opened at around 4K! Why would the resistance (I’m guessing) change on the ‘to earth’ kill curcuit?! Also the chances of getting a 3 wire servo with a black/white stripe? As well as the black/white wire from the loom being changed?! That’s some fuxin cosmic improbability going on. Whiskey Tango Foxtrot is going on with My Life?!…

I’ll take some pics when the light is good enough to show the colours properly…

Couldn’t make this shit up!…

Could it possibly be something as banal as a rotten earth to the coil?

It seems it may be that the opposite side to the orange wires earth point (on the coil!) is more important that it’s connected 100% to the loom, rather than the frame…

There is a join in the earth lead from previous abusers. One of those hard plastic crimp jobs. If I’d thought it was essential I’d of looked and addressed it before now! The wire was dry and crumbly between fingers…

Will know tomorrow when I’m alcohol free, but the motor is spooling up really crisp and fast, and the spark seems a lot stronger. I’ve been wrong before though… -

Could it possibly be something as banal as a rotten earth to the coil?

It seems it may be that the opposite side to the orange wires earth point (on the coil!) is more important that it’s connected 100% to the loom, rather than the frame…

There is a join in the earth lead from previous abusers. One of those hard plastic crimp jobs. If I’d thought it was essential I’d of looked and addressed it before now! The wire was dry and crumbly between fingers…

Will know tomorrow when I’m alcohol free, but the motor is spooling up really crisp and fast, and the spark seems a lot stronger. I’ve been wrong before though… -

Still not there, my spark is healthier looking, but still red-orange. I believe a healthy spark should be blue-white?…

PS earth is NOT that important, it still runs with it disconnected

I tried fitting the 3nc CDI, it only fires once then nothing. It has 3 extra wires on it, blue and sky blue (2pin block connector) and blue/yellow-stripe (maybe white) I’m wondering if they’re to do with the side stand kill curcuit. I think I need to manipulate them to make it spark constantly…

Will the bike start with the side stand down and in neutral? Or does the stand have to be up regardless?…

-

Still not there, my spark is healthier looking, but still red-orange. I believe a healthy spark should be blue-white?…

PS earth is NOT that important, it still runs with it disconnected

@SpookDog said in So Close!...:

Still not there, my spark is healthier looking, but still red-orange. I believe a healthy spark should be blue-white?…

PS earth is NOT that important, it still runs with it disconnected

I think you are slowly slipping into my Gordian knot electrical problem.

-

@SpookDog said in So Close!...:

Still not there, my spark is healthier looking, but still red-orange. I believe a healthy spark should be blue-white?…

PS earth is NOT that important, it still runs with it disconnected

I think you are slowly slipping into my Gordian knot electrical problem.

Yeah, I don’t give up easily though. 35 year old looms with black tarnished copper cores can be challenging! This has only started since I removed, stored and replaced the loom. It’s easy to find an intermittent broken inner if it’s just an indicator or tail light wire that you can wobble around. Wires in the core of the loom are another matter

Have you done anything on your bike lately? I know that the weather is still shitty here most of the time…

You’ll have to update your thread with the current situation when you can. We’ll get them running again like they should… -

I feel quite blessed really compared to your situation @SpookDog , I got my DT off a older gentleman at 5500 miles and have had it since. It's been nicked in that time but luckily that was just indicators that I binned off anyway. Your problems sound like what I am going to have with my ETX. That thing is pure trash

-

I feel quite blessed really compared to your situation @SpookDog , I got my DT off a older gentleman at 5500 miles and have had it since. It's been nicked in that time but luckily that was just indicators that I binned off anyway. Your problems sound like what I am going to have with my ETX. That thing is pure trash

-

Yeah, I don’t give up easily though. 35 year old looms with black tarnished copper cores can be challenging! This has only started since I removed, stored and replaced the loom. It’s easy to find an intermittent broken inner if it’s just an indicator or tail light wire that you can wobble around. Wires in the core of the loom are another matter

Have you done anything on your bike lately? I know that the weather is still shitty here most of the time…

You’ll have to update your thread with the current situation when you can. We’ll get them running again like they should…@SpookDog said in So Close!...:

Yeah, I don’t give up easily though. 35 year old looms with black tarnished copper cores can be challenging! This has only started since I removed, stored and replaced the loom. It’s easy to find an intermittent broken inner if it’s just an indicator or tail light wire that you can wobble around. Wires in the core of the loom are another matter

Have you done anything on your bike lately? I know that the weather is still shitty here most of the time…

You’ll have to update your thread with the current situation when you can. We’ll get them running again like they should…I understand,opened twice the 30 year loom completely,once when rebuilding and now when searching for the electrical problems.Second time was 3 times the searching test&time of the first.I believe now is almost new.

I haven't done much because the bad weather most of the time,no light to work after sunset,2 small kids so almost no spare time and my health problem.

I hope so,need so much to ride again it's like a dream for me now. -

@SpookDog All sounds good!

If the bike still runs I doubt you've done any damage to the CDI by crossing those wires, usually CDI units either work or they don't. Interesting it did still work though; the black/yellow wire tells the little on-board computer inside the 3-wire servo the engine speed (like the crank sensor on a car) and the black/white wire stops the plug sparking by earthing the CDI when you flick the kill switch or turn off the ignition, so I guess if you hooked either of those wires from the CDI up to some test equipment like an oscilloscope, you'd probably get some quite similar results.

Keep us posted for any improvements!

I’ve found the 2 wires that the starter solenoid joins to the loom by, also a wire that appears to be the clutch switch.

What stator did these 3mb RE’s use bud, any idea?…

—————————-Edit: I managed to get the 3nc CDI working thanks to HotShots 3mb wiring diagram. Turns out that the wire that goes to the side stand, from the CDI, needed earthing…

Will test it out later when I can…——————————

PS if this doesn’t cure it I’ll have to try swapping out the carb for the tzr one or my old one. I’m wondering if the choke plunger rubber is worn and not sealing properly.

Also the ignition coil on the stator and the wiring between it and the CDI unit…

I can’t think of anything else at the moment…

Still getting light missing at low revs and an orange/red spark…I replaced the connector & wiring from pickup to CDI. Repaired a connection & wiring in the orange coil wire as well.

-

I’ve found the 2 wires that the starter solenoid joins to the loom by, also a wire that appears to be the clutch switch.

What stator did these 3mb RE’s use bud, any idea?…

—————————-Edit: I managed to get the 3nc CDI working thanks to HotShots 3mb wiring diagram. Turns out that the wire that goes to the side stand, from the CDI, needed earthing…

Will test it out later when I can…——————————

PS if this doesn’t cure it I’ll have to try swapping out the carb for the tzr one or my old one. I’m wondering if the choke plunger rubber is worn and not sealing properly.

Also the ignition coil on the stator and the wiring between it and the CDI unit…

I can’t think of anything else at the moment…

Still getting light missing at low revs and an orange/red spark…I replaced the connector & wiring from pickup to CDI. Repaired a connection & wiring in the orange coil wire as well.

@Me!…

It would appear that a hot wired £25 CDI unit bought from fleabay has cured the low rpm problems! 25 miles with no noticeable pops or hesitation! I’ll check again tomorrow after I’ve adjusted the new slack in my chain…

But for the time being I am optimistic!…

️

️

-

@Me!…

It would appear that a hot wired £25 CDI unit bought from fleabay has cured the low rpm problems! 25 miles with no noticeable pops or hesitation! I’ll check again tomorrow after I’ve adjusted the new slack in my chain…

But for the time being I am optimistic!…

️

️

Last post of the day!…

Sparks?! I believe that they should be fat blue~white, yes? If mine are orange ~red then I’m wondering if the capacitors in the CDI unit are getting enough electrickery to generate constant good blue ~white sparks? Even if this could contribute to the demise of a CDI unit? (Serious Deja Vu here somehow)

I’m thinking of changing out the ignition ~source coil and the wiring from the stator to the CDI unit anyways...

I would seriously love some feedback about spark colour and strength…

…

…