Yamaha DT125R '01 - Running Project

-

@Calum Yeah, Not sure what is going on with it, I copy the embed link but still get all the text? Not happend before. But it works no other way on here, Werid. Problem my end.

Tis quite soft ally, but 6mm plate should suffice any deformation. It's a strong bracket. I would prefer to watercut and plate some steel.

As for keeping up with the Aprilia boys, well.Impossible on any open' road true! I will own a Rotax 122 one day. Nearly got a 1996 Aprilia RX125. Fantastic engines that CAN indeed be very reliable much too everybody's misconception of them. Although holding them at 12k all Sunday is the addictive demise of thy road 2stroke. Expensive past times.

But yeah cheers dude.

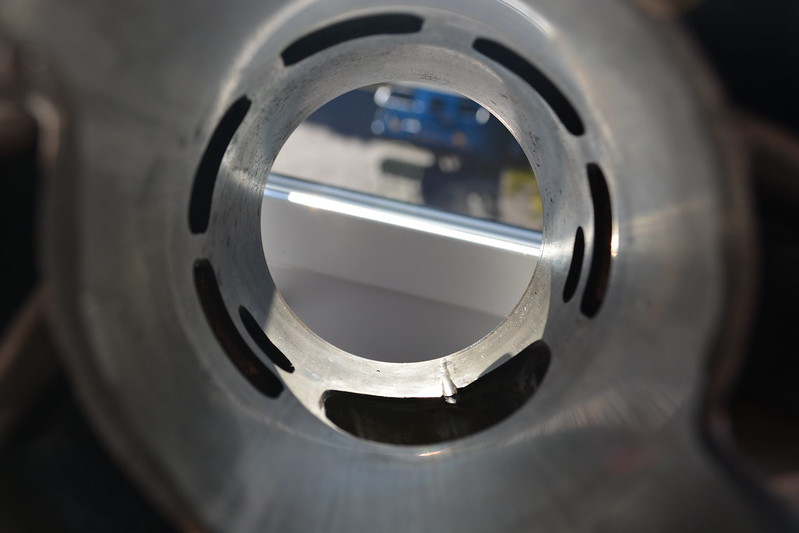

No 8,500 Rpm Will not suffice. (Picture Illustrates nothing usefull) Just browsing.

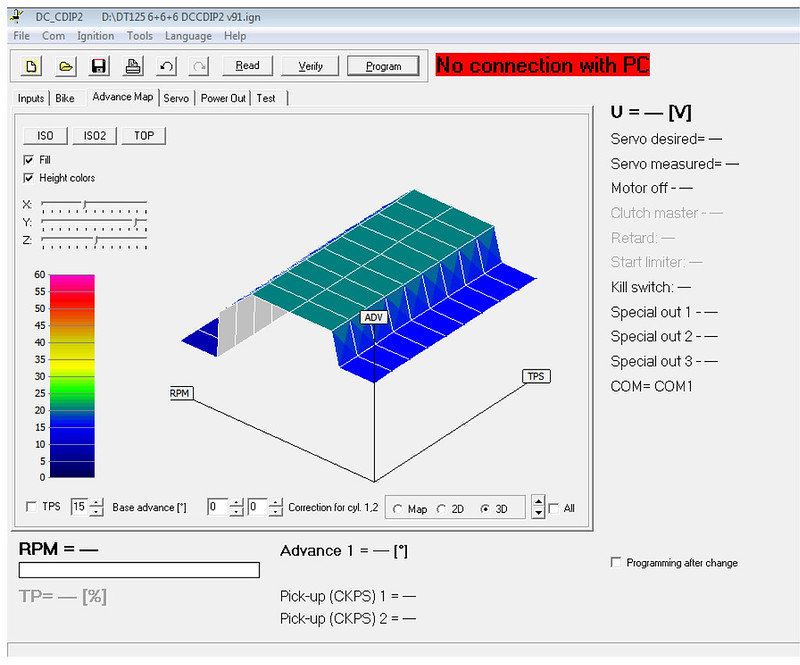

Had a little peak at the Ignitech Software and Manual. Love this stuff. Pretty unnecessary for this project but it gives some good performance options. (The main reason I bought this was too eliminate the Factory CDI ignition retardation.) It's not necessary but increasing the Max Rev Range is important for any gains in gearing at this point. Also advancing the timing is a very easy performance gain. If you do this Beware of using lower octane fuel. Pretty noticeable.

Bike was sweating in the shed. The plating and steel are so thin on these DT125R Dep's. I hate them. Bad build quality for the money, but indeed the best pipe for it all rounder wise. Mines starting to blow holes.

Electrolysis!

Electrolysis is a process by which Ferric Oxide (Pesky rust...) is turned back into Iron. Had De-Rusting tank set up already. I was worried it would attack the chrome slightly but it is absolutely fine.

'Function over form' and silver exhaust paint is applied. Ah well. the Chrome had excellent heat distortion and looked well worked in loveely purpley Gold. But it is an expendable right? Best try and keep it from disitergrating. Think I will try and wrap it in Ceramic Fibre cloth, Keep it covered.

The inlet and Carburetor just is not where I want it to be. Needs to sit in there as Factory as it can be. I've made a template out of card using a Reed Spacer as a base template. Definitely going to have to make a Inlet. I fabricate it, but damn, I'm not doing Tig anytime soon, Great. Got some time to kill anyway.

Could print one? Haha will delve into that soon.

The wheel base has increased some 100mm. Same length as a WR200 and 20mm longer than a same era YZ. Success. Got some FZR400 Tie bars which are 150mm. perfect lowering height, but not the same thickness steel and are plastic coated not plated? Had too drill them out to 16mm to accept the DT's chunkier linkage bolts. Cheap fix. Not recommended.

Any help please with a chain. I cannot find a 428 Heavy Duty Drive chain that is long enough.. like anywhere. Probably will go 520 and Sprockets because I've got a spare. But a 428 would be bang on and standard.

. -

Got digging around the ol' interweb and quickly realised the Radiators I received were indeed. WR200 units..This explains why my plan never worked as I hoped. Ohh well it's close enough,

DT200R Right H

WR200 Right H

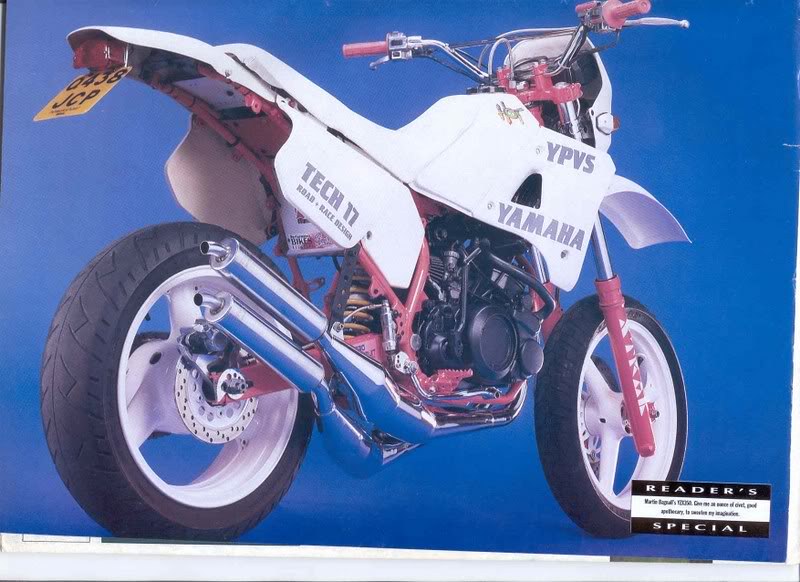

Unrelated note, Saw this wicked early 90s DT-RD350/TZR Supermoto ages ago on the net. Found it again recently. Got me thinking about all the great projects I have seen.

MOT coming February, Fork conversion towards Easter. Not ridden the ol girl in vein for too long.

-

You don't need the embedded link. Just the image location with no fancy embed stuff.

Comming along nicely. Yeah I thought that about the dep pipe too. I ditched my pipe in the end. Disgusted by the poor quality metal. Good performance gains though.

Yeah I was jawing over that rd project for a long time haha!

As far as the cdi is concerned. Bang for buck it's the best modification and I have done the lot.

Good luck with the mot keep us posted.

-

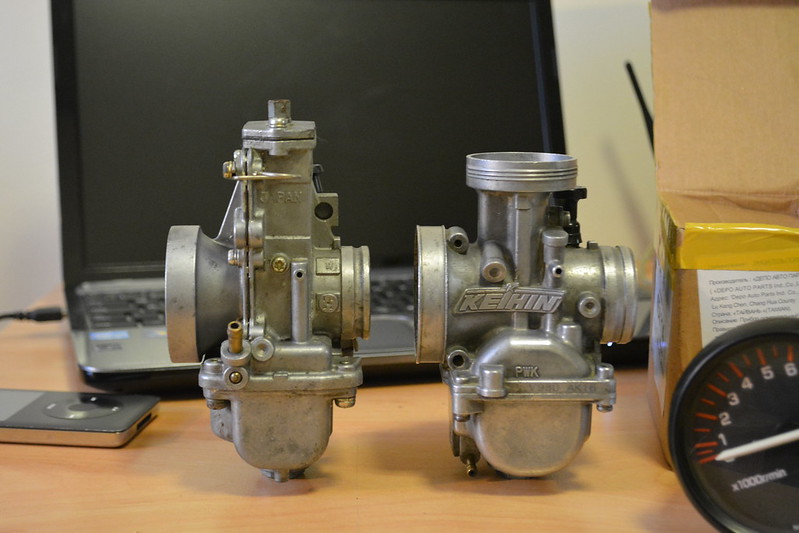

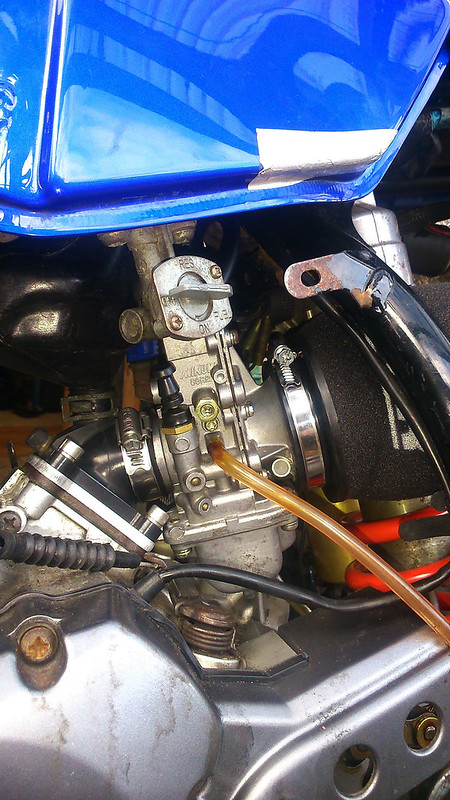

Decided against using the Kehin 36. Effort. it's not going to give me the right results. Went shopping, but I could not find anything suitable accept for a couple of Dell'orto VH34s or old TMX34's for reasonable price. Don't need anything bigger right now.

Got this Mikuni TM32 which desperately needs a clean and polish. And a float bowl. It's been mangled.

Who needs a digital display?

Got this TZR Tachometer. Love the dial, goes to 12k. Yamaha part, perfect. You can always feel what the engine is doing, but it's nice to see what's going on. Not too useful, and it's rather big, but a single clock up front, clean, simple on the WR yoke.

I prefer the Mikuni TM series + this version has the Fuel inlet on the right side. Wont bother with using the Airbox.

-

So, gave up on the MOT. All because of a couple of Mikuni Pilot Jets. Postage took too long, could not finish it up.

Jetting for an Open Air filter is a pain in the rear. Factory settings don't really apply and she's leaner than I anticipated. Which is kind of fun in a boring way. Jetting is the cheapest power you can buy! Best get it right.

Dep header is swiss cheese so I wrapped it for now using Titanium fibre exhaust wrap. Operating temperature for the expansion pipe should be better? Hotter pipe to help control the temperature of exhaust gases. New pipe has to wait. Ah well. it's a Student build.

Don't ever use that GumGum tape, pastey shite. Just awful on a header pipe.

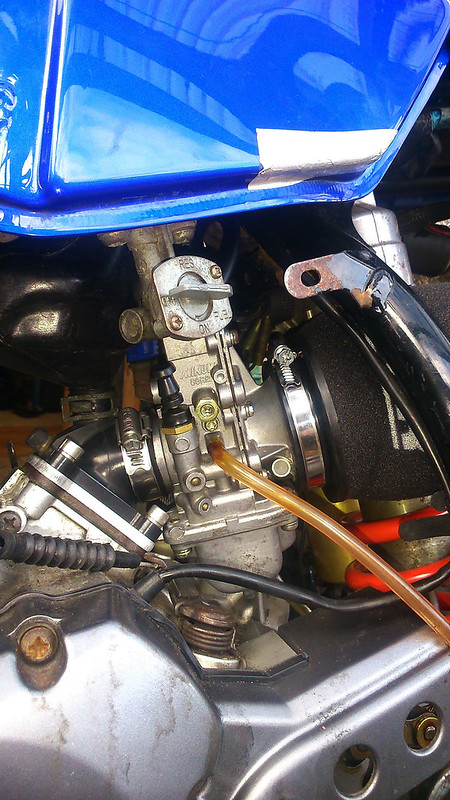

May have got impatient and dremel'd out the standard Inlet manifold. Pluged over the Oil injection entry and smoothed out and increased the bore size internally and opened the flange 28-32mm.

Good thing about the standard manifold is the YIES boost bottle. Adds some much needed refinement to the 2 stroke.

Increasing the bore I had to trim the bottom of the YIES snout as it protrudes further into the bore and will potentially disrupt airflow.

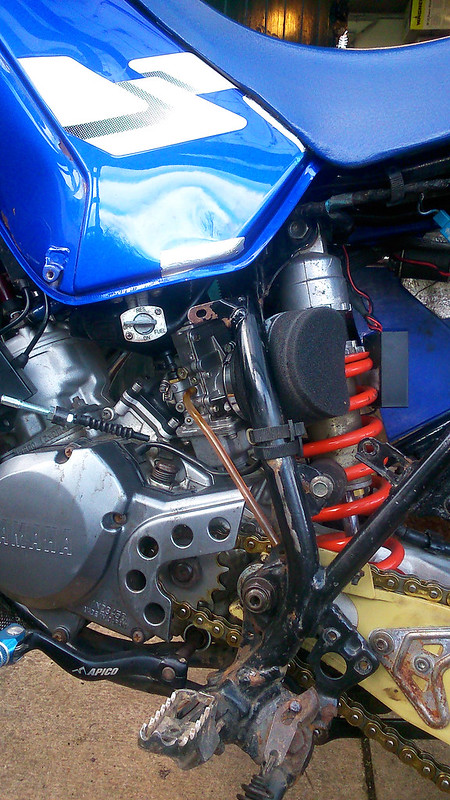

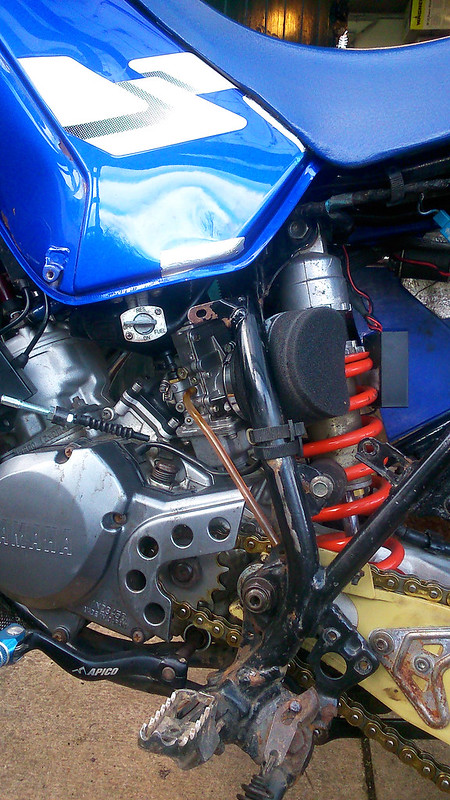

The air filter and carb only just fits in and its bent around the YZ shocker. So tight and a bitch to get in and out.

Running 520 YZ125 AFAM chain 13T drive sprocket and Talon 51T rear. Makes it perky. She sounds like a beast with and without the airbox amplifying it.

-

So, gave up on the MOT. All because of a couple of Mikuni Pilot Jets. Postage took too long, could not finish it up.

Jetting for an Open Air filter is a pain in the rear. Factory settings don't really apply and she's leaner than I anticipated. Which is kind of fun in a boring way. Jetting is the cheapest power you can buy! Best get it right.

Dep header is swiss cheese so I wrapped it for now using Titanium fibre exhaust wrap. Operating temperature for the expansion pipe should be better? Hotter pipe to help control the temperature of exhaust gases. New pipe has to wait. Ah well. it's a Student build.

Don't ever use that GumGum tape, pastey shite. Just awful on a header pipe.

May have got impatient and dremel'd out the standard Inlet manifold. Pluged over the Oil injection entry and smoothed out and increased the bore size internally and opened the flange 28-32mm.

Good thing about the standard manifold is the YIES boost bottle. Adds some much needed refinement to the 2 stroke.

Increasing the bore I had to trim the bottom of the YIES snout as it protrudes further into the bore and will potentially disrupt airflow.

The air filter and carb only just fits in and its bent around the YZ shocker. So tight and a bitch to get in and out.

Running 520 YZ125 AFAM chain 13T drive sprocket and Talon 51T rear. Makes it perky. She sounds like a beast with and without the airbox amplifying it.

-

Nice work there, liking the fabrication. I have often thought about a dt200r or wr200 swingarm but I spent ages getting the old bearings out of mine and powdercoating it so I left it. So it was a perfect fit you say? Except the dog bones.

Fitting a different carburetor was also a nightmare, especially on a divided throttle cable (I'm running auto lube on my 200cx conversion) I had a tm32 flat side which was very tricky to fit because it isn't angle on the spigots. If you carb isn't level enough it can mess with the floats. I then ran a tmx30 carburetor very similar to the wr200s tm30ss carburetor which ran very nicely and few modifications. And I am currently running a tm34ss which has angled spigots. Which I'd recommend

-

Nice work there, liking the fabrication. I have often thought about a dt200r or wr200 swingarm but I spent ages getting the old bearings out of mine and powdercoating it so I left it. So it was a perfect fit you say? Except the dog bones.

Fitting a different carburetor was also a nightmare, especially on a divided throttle cable (I'm running auto lube on my 200cx conversion) I had a tm32 flat side which was very tricky to fit because it isn't angle on the spigots. If you carb isn't level enough it can mess with the floats. I then ran a tmx30 carburetor very similar to the wr200s tm30ss carburetor which ran very nicely and few modifications. And I am currently running a tm34ss which has angled spigots. Which I'd recommend

Ah cheers boys, @Calum @ConnorDTR there is still so much I need to do. Not enough time!

@Louis-James Yeah, pretty much a perfect fit. I had to turn a spacer on the sprocket side of the swingarm because there is a gap between the bearing end cap and the crankcase, WR200 crankcase must have a wider section across the swingarm bolt.

Fits fine without it, but needs the spacer for the correct lateral torque. But it's a bolt in job and I really recommend it.

Definitely get yourself the WR200 linkage set (Alloy) I need to fit mine then you can potentially run very nice rear dampers from a newer generation. Got a nice TM Ohlins shock, looks to fit.

The TM32 isn't a great fit, I've not run it for long, but it's possible it's already disrupting the floats. But fit for purpose just. Not ideal. Just had a look at some TM34Ss and yeah man, that looks to be a much better idea actually.

Ultimately I think you have got too make a Inlet manifold, I can't fit anything else past the shock without one.

-

Spring has crept around ol' Coventry today. Blessed. And then some bits finally turned up at lunch time.

POWER.

Most of Yamaha's road going production castings are begging to be cleaned up gone over properly, because the castings make you wince in places. They are cost effective without hand finishing and, of course the time and labour is not necessary for a production run. Not even because it's old, they need some love.

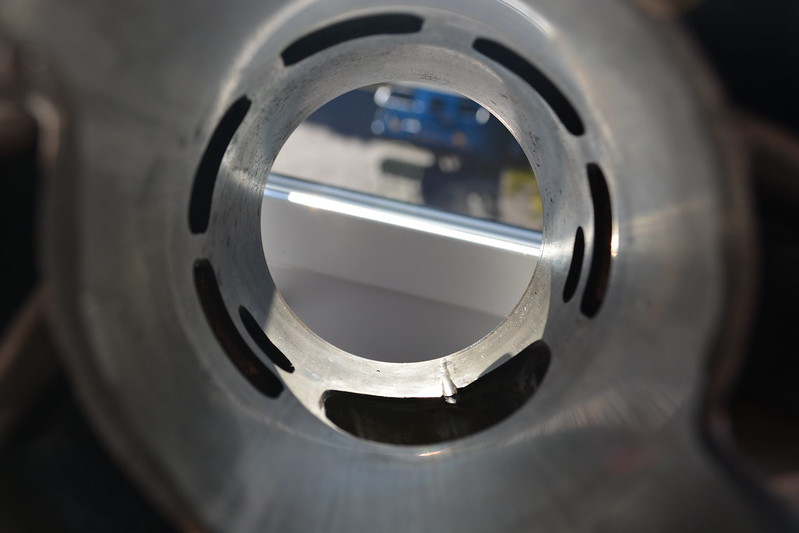

Wrekt...She's a bit of a lemon. Cracked the sleeve to the top above the exhaust port. Still, new sleeve and some light repair work around the port and she's good to go. This will be the test mule for running a larger bore.

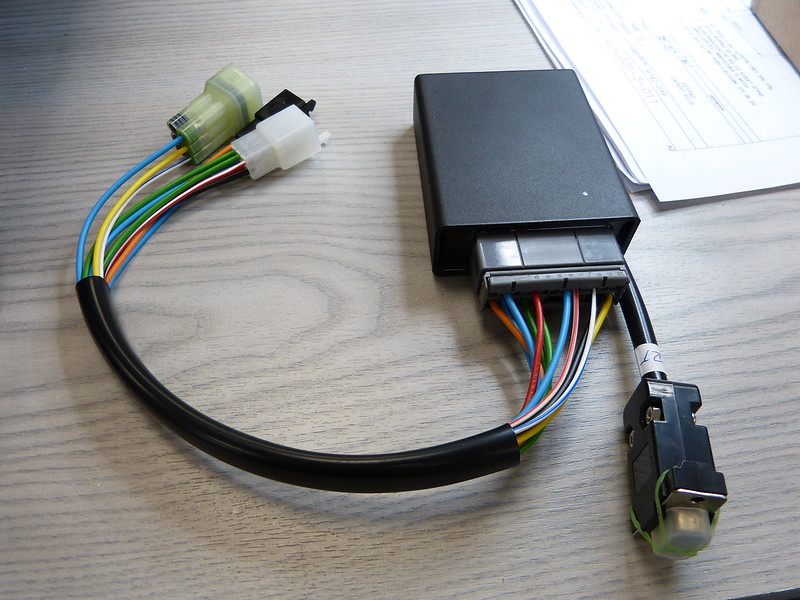

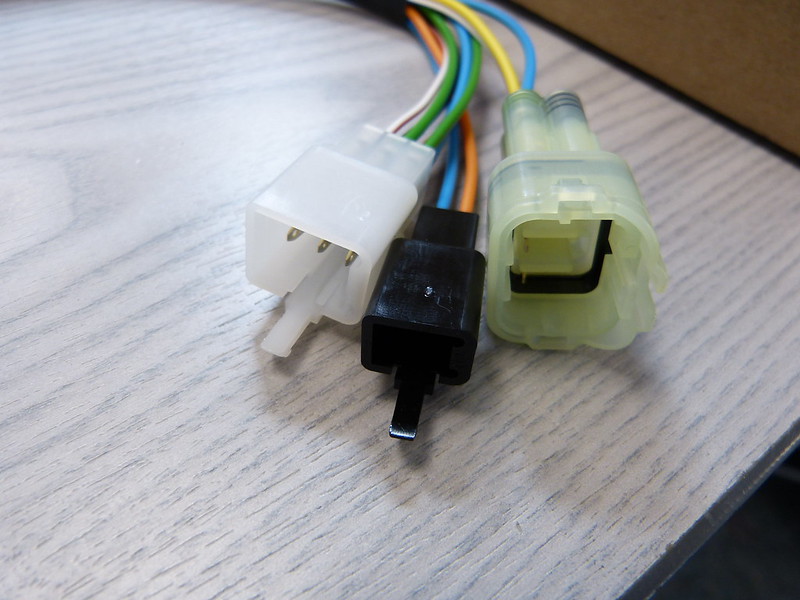

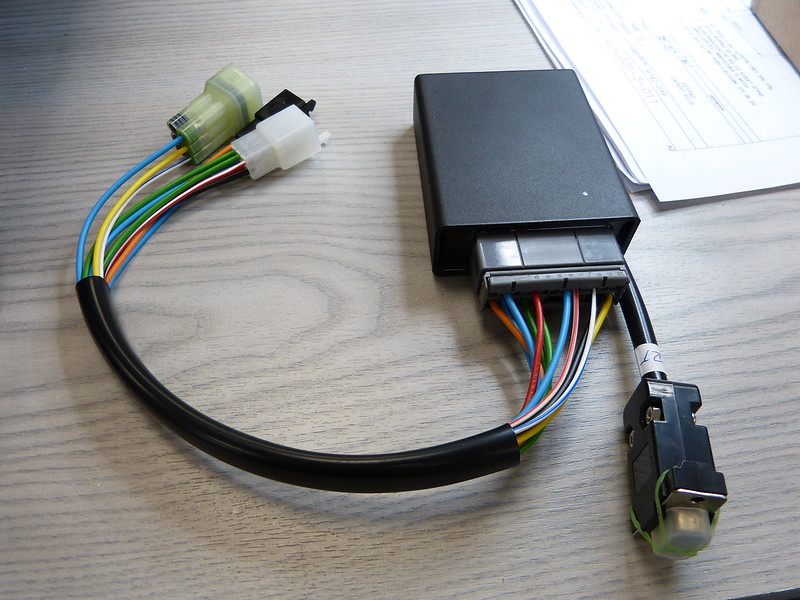

Ignitech came through, I should of spec'd a longer loom so I could fit it into the now empty airbox. There isn't much of anywhere with decent access and tucked in.

Looking forward to building up a 200R block.. maaybe some time on that.

Anyone want some money for a WR200 powervalve they somehow don't need? I'm your man.

-

Very smart. Nice auxiliary exhaust ports on them too! Should be a beast.

Powervalves are tricky things to come by. I askrd about having one made but they simply wouldn't do it because of cost!

Very frustrating but I am sure you will find one one day!

Easy on how you remove that sleeve. Even companies have been known to damage the ally cylinder removing them.

Will.keep an eye out for updates.

-

You can buy new sleeves on eBay, I saw some wiseco ones a few years back. I have the nickasil bore, not sure what models had what

-

-

Spring has crept around ol' Coventry today. Blessed. And then some bits finally turned up at lunch time.

POWER.

Most of Yamaha's road going production castings are begging to be cleaned up gone over properly, because the castings make you wince in places. They are cost effective without hand finishing and, of course the time and labour is not necessary for a production run. Not even because it's old, they need some love.

Wrekt...She's a bit of a lemon. Cracked the sleeve to the top above the exhaust port. Still, new sleeve and some light repair work around the port and she's good to go. This will be the test mule for running a larger bore.

Ignitech came through, I should of spec'd a longer loom so I could fit it into the now empty airbox. There isn't much of anywhere with decent access and tucked in.

Looking forward to building up a 200R block.. maaybe some time on that.

Anyone want some money for a WR200 powervalve they somehow don't need? I'm your man.

@Darty I have a wr200 powervalve spare

-

@Darty I have a wr200 powervalve spare

-

@Darty I'll get some tomorrow I think it's baggy on the two joining downs but could be filled

-

@Dartyhttp://rs1083.pbsrc.com/albums/j388/louisgar/Mobile%20Uploads/DSC_0861_zpsufktz9sf.jpg?w=480&h=480&fit=clip

-

So what's the difference with the ignitech CDI and the Zeeltronic? Only just heard of the ignitechs

@ConnorDTR The main difference is the interface design and the ZEELYS are bit more intuitive to use I reckon. But I like the software from Ignitech, you can just drag points across your curve and it's easy to fiddle with. For a Single cylinder PV anyway.

Technically wise, Ignitech can prove less accurate and power valve control is not as good to setup as the ZEEL.. coming from some heavy tuners, but for average Joe bloggs, they are on par and the Ignitechs are way cheaper. I spec'd mine all in £115. Get a PC connector somewhere else.