Yamaha DT125R '01 - Running Project

-

I did the whole polishing thing when I first started building my cr but by the time I finished I had decided I didn't wanna polish after every ride so I powder coated it black instead, did look the part tho@andrewj1680 Oh man, that sure looks damn sweet, and such a shame to do all that work and then get all that lovely shiny metal blacked out. But hey-hoo I get why and it was your choice.

-

@andrewj1680 Oh man, that sure looks damn sweet, and such a shame to do all that work and then get all that lovely shiny metal blacked out. But hey-hoo I get why and it was your choice.

@CYBER-NINJA I preferred the polished look but I'd of spent more time polishing it than riding it every time I took it out, Can you imagine trying to avoid every puddle you came across lol that wasn't for me if it's there I'm gonna ride it

-

(6mm Stainless Steel - Brass 13-14mm spacers)

I made DXF files for Waterjet cutting - for a Stainless Calliper adapter and spacers for a SM conversion using the 'YZF125' Brembo calliper.

If there are a few members here looking to do SM conversions, I could get a few kits together with bolts,

Just a limited run as I have the time for the moment.

-

32 degrees, sticky rubber, cotswold country lanes, 2strokes and considerable beer intake on par with University life.

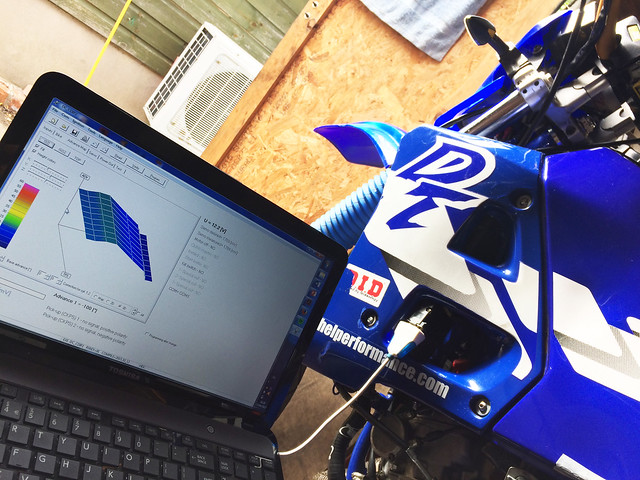

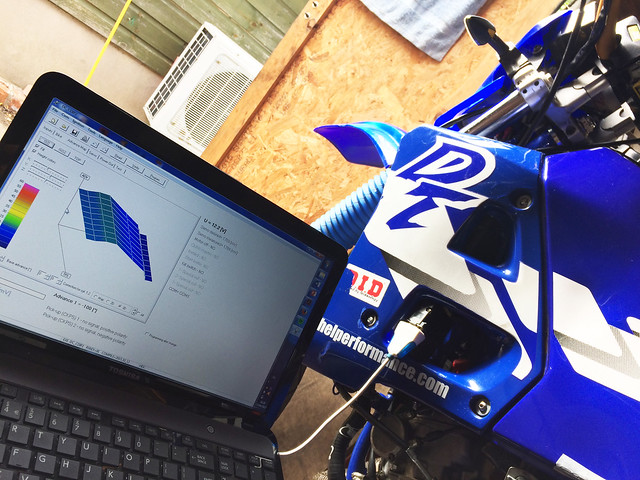

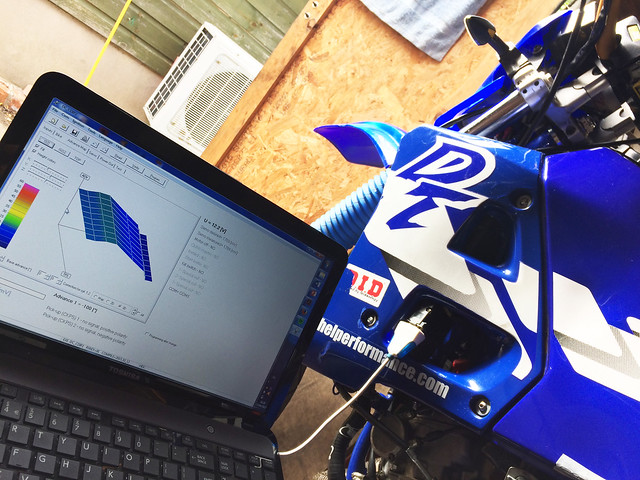

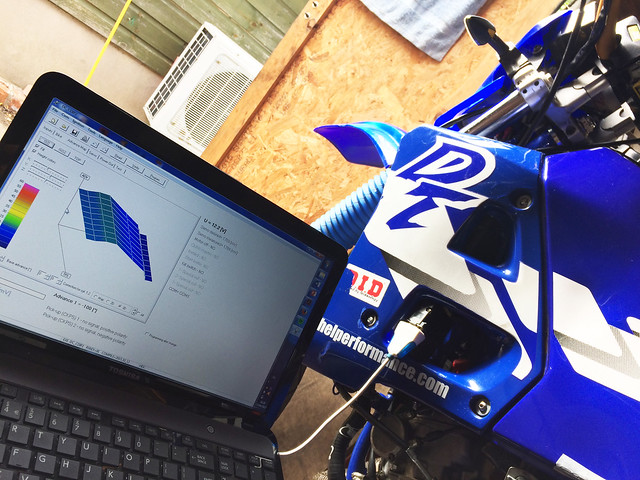

I ride this thing 22 miles a day as a daily to go work, built this thing to be used and I just 'turn it up' a little on the Laptop for a blitz on the weekend somewhere.

Drawing this project to a close, and enjoying the result, or atleast this iteration of it so far...

I had some clearance issues with the Powervalve under expansion. I removed material in increments by machine sanding.

Custom bracket for the FMF Powercore1 can. Fits on a DTR well.

Built the headlight brackets,

WR400 Face swap.

There is no room left on this bike. Made a mount for the Ignitech Ignition, secure, doesn't suffer from heat exposure and most importantly it's accessible.

As for cooling, air flow is fine still.

Modified AS3 Silicone WR200 radiator hose's to suit this mongrel application.

This leads me to something interesting I found,

I needed a new WR200 coolant pipe, turns out later 4BF4 1995' WR200s use a larger 18mm bore coolant pipe.

I got one brand new old stock from Japan. I've rust protected it, primer and a Gold top coat for a little bling.

Then of course a 4BF4 Waterpump cover is required.

4BF4' Pictured above vs 125R/200R

I never knew Yamaha updated the cooling for the WR200, so I had help getting a used one.

IT ONLY JUST FITS... Tight bruuuh. I made a brace for the coolant down pipe as it's just a braised joint and I managed to split my last one like a clot.

Originally this mounts onto the WR200 Cylinder, so ideally this has to be done to the 125R barrel.

Cooling is now more than adequate,

WR200 Inlet, TM32 fitted. This inlet gives you more angle to use larger carburettor bodies.

WR200 vs DT125R. Inlet tract a little longer, Mounting points have to be modified and crankcase stuffers removed.

New YZ braided brake lines and removable exhaust joint to get the FMF onto the DEP.

(An oldschool mechanical display setup. Dorky but I love this older stuff.

The fun bits. Built to be ridden alot!

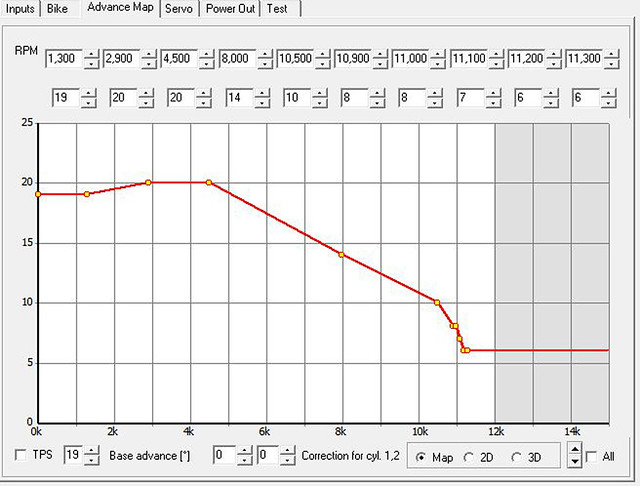

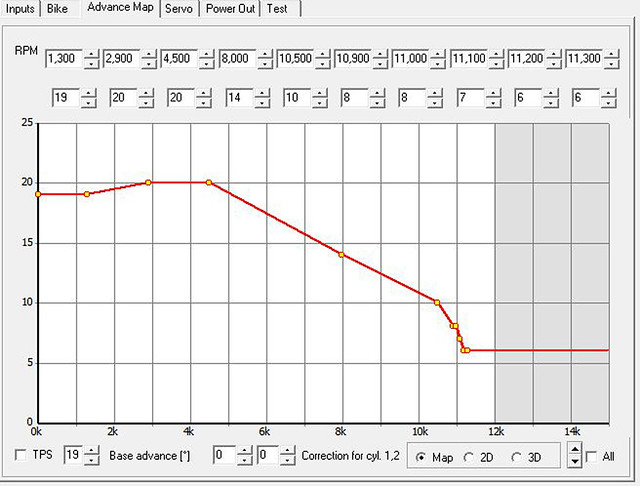

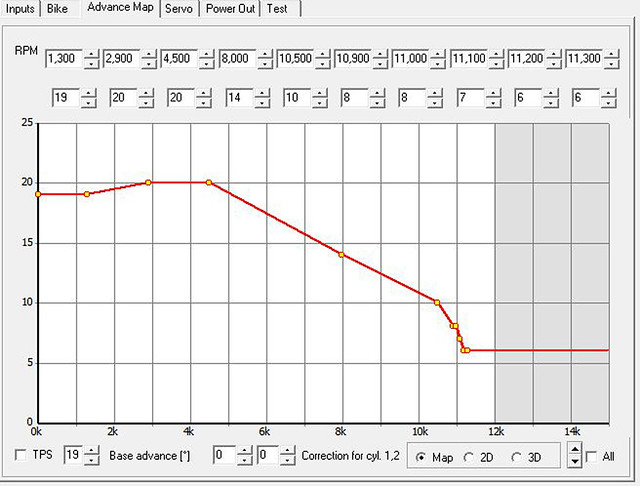

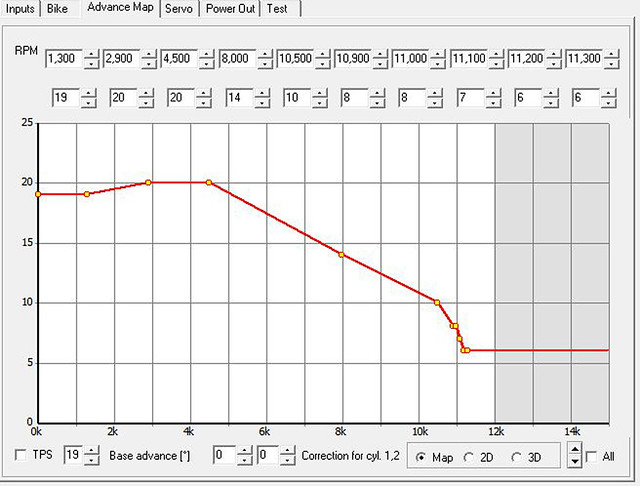

Using a base map close to a TZR125 4DL SP, It runs particularly well under 6K.

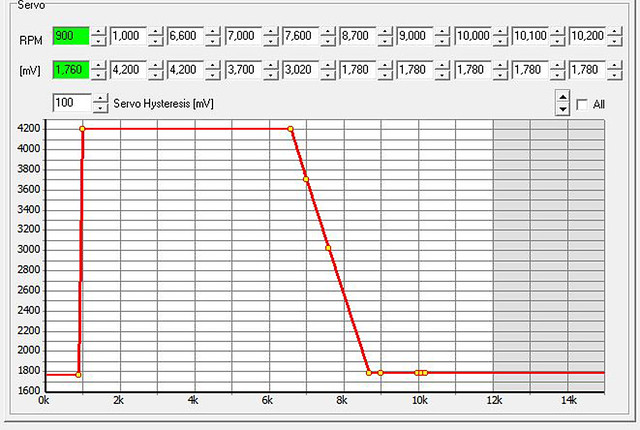

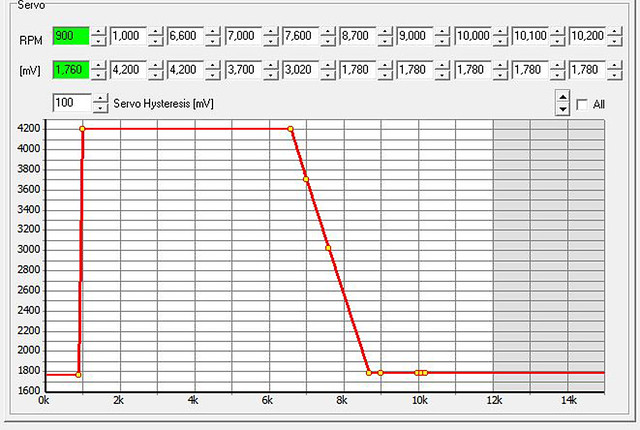

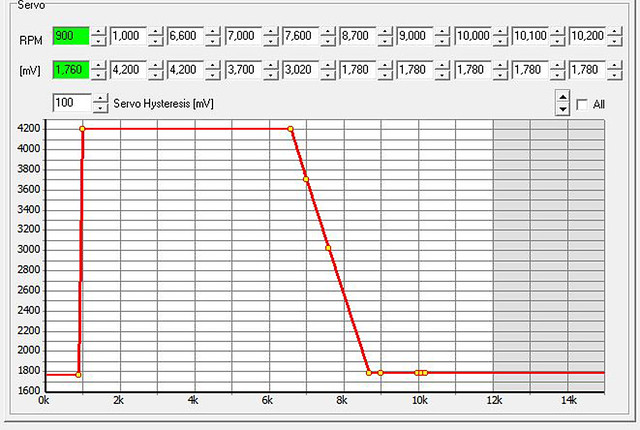

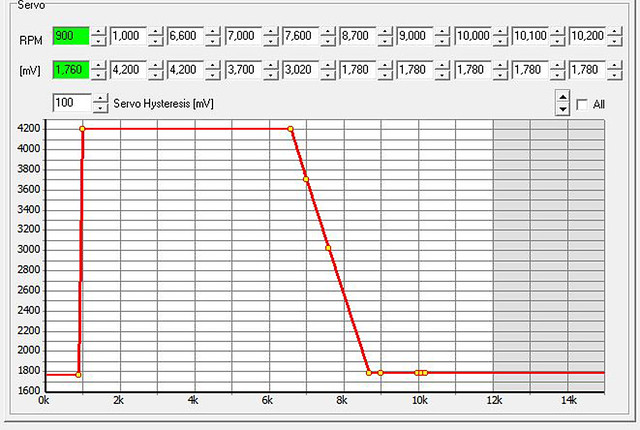

This DT now shifts.. I use a 4DL servo setting which utilises the PV opening later than the DT or TDR 3SH.

It's far from perfect, but a safe base tune to run on as this is my daily as the weather is so good.

It's run in properly now, and it is glorious. It sounds fantastic over 10,000rpm.Powerband is up at 9,500rpm and it pulls hard to 13,000.

DTR Gear ratios are perfect for this TZR head and it's acceleration characteristic is spot on, 0-62 less than 6 seconds.

More to come, more bits from Japan to arrive and then finally a Dyno session with a TM34ss fitted.

Stay safe!

-

32 degrees, sticky rubber, cotswold country lanes, 2strokes and considerable beer intake on par with University life.

I ride this thing 22 miles a day as a daily to go work, built this thing to be used and I just 'turn it up' a little on the Laptop for a blitz on the weekend somewhere.

Drawing this project to a close, and enjoying the result, or atleast this iteration of it so far...

I had some clearance issues with the Powervalve under expansion. I removed material in increments by machine sanding.

Custom bracket for the FMF Powercore1 can. Fits on a DTR well.

Built the headlight brackets,

WR400 Face swap.

There is no room left on this bike. Made a mount for the Ignitech Ignition, secure, doesn't suffer from heat exposure and most importantly it's accessible.

As for cooling, air flow is fine still.

Modified AS3 Silicone WR200 radiator hose's to suit this mongrel application.

This leads me to something interesting I found,

I needed a new WR200 coolant pipe, turns out later 4BF4 1995' WR200s use a larger 18mm bore coolant pipe.

I got one brand new old stock from Japan. I've rust protected it, primer and a Gold top coat for a little bling.

Then of course a 4BF4 Waterpump cover is required.

4BF4' Pictured above vs 125R/200R

I never knew Yamaha updated the cooling for the WR200, so I had help getting a used one.

IT ONLY JUST FITS... Tight bruuuh. I made a brace for the coolant down pipe as it's just a braised joint and I managed to split my last one like a clot.

Originally this mounts onto the WR200 Cylinder, so ideally this has to be done to the 125R barrel.

Cooling is now more than adequate,

WR200 Inlet, TM32 fitted. This inlet gives you more angle to use larger carburettor bodies.

WR200 vs DT125R. Inlet tract a little longer, Mounting points have to be modified and crankcase stuffers removed.

New YZ braided brake lines and removable exhaust joint to get the FMF onto the DEP.

(An oldschool mechanical display setup. Dorky but I love this older stuff.

The fun bits. Built to be ridden alot!

Using a base map close to a TZR125 4DL SP, It runs particularly well under 6K.

This DT now shifts.. I use a 4DL servo setting which utilises the PV opening later than the DT or TDR 3SH.

It's far from perfect, but a safe base tune to run on as this is my daily as the weather is so good.

It's run in properly now, and it is glorious. It sounds fantastic over 10,000rpm.Powerband is up at 9,500rpm and it pulls hard to 13,000.

DTR Gear ratios are perfect for this TZR head and it's acceleration characteristic is spot on, 0-62 less than 6 seconds.

More to come, more bits from Japan to arrive and then finally a Dyno session with a TM34ss fitted.

Stay safe!

-

32 degrees, sticky rubber, cotswold country lanes, 2strokes and considerable beer intake on par with University life.

I ride this thing 22 miles a day as a daily to go work, built this thing to be used and I just 'turn it up' a little on the Laptop for a blitz on the weekend somewhere.

Drawing this project to a close, and enjoying the result, or atleast this iteration of it so far...

I had some clearance issues with the Powervalve under expansion. I removed material in increments by machine sanding.

Custom bracket for the FMF Powercore1 can. Fits on a DTR well.

Built the headlight brackets,

WR400 Face swap.

There is no room left on this bike. Made a mount for the Ignitech Ignition, secure, doesn't suffer from heat exposure and most importantly it's accessible.

As for cooling, air flow is fine still.

Modified AS3 Silicone WR200 radiator hose's to suit this mongrel application.

This leads me to something interesting I found,

I needed a new WR200 coolant pipe, turns out later 4BF4 1995' WR200s use a larger 18mm bore coolant pipe.

I got one brand new old stock from Japan. I've rust protected it, primer and a Gold top coat for a little bling.

Then of course a 4BF4 Waterpump cover is required.

4BF4' Pictured above vs 125R/200R

I never knew Yamaha updated the cooling for the WR200, so I had help getting a used one.

IT ONLY JUST FITS... Tight bruuuh. I made a brace for the coolant down pipe as it's just a braised joint and I managed to split my last one like a clot.

Originally this mounts onto the WR200 Cylinder, so ideally this has to be done to the 125R barrel.

Cooling is now more than adequate,

WR200 Inlet, TM32 fitted. This inlet gives you more angle to use larger carburettor bodies.

WR200 vs DT125R. Inlet tract a little longer, Mounting points have to be modified and crankcase stuffers removed.

New YZ braided brake lines and removable exhaust joint to get the FMF onto the DEP.

(An oldschool mechanical display setup. Dorky but I love this older stuff.

The fun bits. Built to be ridden alot!

Using a base map close to a TZR125 4DL SP, It runs particularly well under 6K.

This DT now shifts.. I use a 4DL servo setting which utilises the PV opening later than the DT or TDR 3SH.

It's far from perfect, but a safe base tune to run on as this is my daily as the weather is so good.

It's run in properly now, and it is glorious. It sounds fantastic over 10,000rpm.Powerband is up at 9,500rpm and it pulls hard to 13,000.

DTR Gear ratios are perfect for this TZR head and it's acceleration characteristic is spot on, 0-62 less than 6 seconds.

More to come, more bits from Japan to arrive and then finally a Dyno session with a TM34ss fitted.

Stay safe!

-

32 degrees, sticky rubber, cotswold country lanes, 2strokes and considerable beer intake on par with University life.

I ride this thing 22 miles a day as a daily to go work, built this thing to be used and I just 'turn it up' a little on the Laptop for a blitz on the weekend somewhere.

Drawing this project to a close, and enjoying the result, or atleast this iteration of it so far...

I had some clearance issues with the Powervalve under expansion. I removed material in increments by machine sanding.

Custom bracket for the FMF Powercore1 can. Fits on a DTR well.

Built the headlight brackets,

WR400 Face swap.

There is no room left on this bike. Made a mount for the Ignitech Ignition, secure, doesn't suffer from heat exposure and most importantly it's accessible.

As for cooling, air flow is fine still.

Modified AS3 Silicone WR200 radiator hose's to suit this mongrel application.

This leads me to something interesting I found,

I needed a new WR200 coolant pipe, turns out later 4BF4 1995' WR200s use a larger 18mm bore coolant pipe.

I got one brand new old stock from Japan. I've rust protected it, primer and a Gold top coat for a little bling.

Then of course a 4BF4 Waterpump cover is required.

4BF4' Pictured above vs 125R/200R

I never knew Yamaha updated the cooling for the WR200, so I had help getting a used one.

IT ONLY JUST FITS... Tight bruuuh. I made a brace for the coolant down pipe as it's just a braised joint and I managed to split my last one like a clot.

Originally this mounts onto the WR200 Cylinder, so ideally this has to be done to the 125R barrel.

Cooling is now more than adequate,

WR200 Inlet, TM32 fitted. This inlet gives you more angle to use larger carburettor bodies.

WR200 vs DT125R. Inlet tract a little longer, Mounting points have to be modified and crankcase stuffers removed.

New YZ braided brake lines and removable exhaust joint to get the FMF onto the DEP.

(An oldschool mechanical display setup. Dorky but I love this older stuff.

The fun bits. Built to be ridden alot!

Using a base map close to a TZR125 4DL SP, It runs particularly well under 6K.

This DT now shifts.. I use a 4DL servo setting which utilises the PV opening later than the DT or TDR 3SH.

It's far from perfect, but a safe base tune to run on as this is my daily as the weather is so good.

It's run in properly now, and it is glorious. It sounds fantastic over 10,000rpm.Powerband is up at 9,500rpm and it pulls hard to 13,000.

DTR Gear ratios are perfect for this TZR head and it's acceleration characteristic is spot on, 0-62 less than 6 seconds.

More to come, more bits from Japan to arrive and then finally a Dyno session with a TM34ss fitted.

Stay safe!

-

Yeah me 2

-

@declan Cheers boss, yeah I guess it hasn't risen much, it's not running right at top end RPM's. Possibly the Reeds failing.

It's amazing how much more torquey it is than before, it's not a bad commuter bike still

@Darty this is what’s sat at the top of my tabs list for the past 4 weeks, your bike build. It’s Mk1 stage with the aprillia headlight and YZ wheels is probably my biggest inspiration for my bike to date. Timeless classic looking crosser and I can’t relp but keep looking at or referring to the pictures of it late at night

(when I’m on eBay that is and not a certain other website

(when I’m on eBay that is and not a certain other website  )

) -

@Darty this is what’s sat at the top of my tabs list for the past 4 weeks, your bike build. It’s Mk1 stage with the aprillia headlight and YZ wheels is probably my biggest inspiration for my bike to date. Timeless classic looking crosser and I can’t relp but keep looking at or referring to the pictures of it late at night

(when I’m on eBay that is and not a certain other website

(when I’m on eBay that is and not a certain other website  )

)@dtStevie98

Lost but not forgotten, back on a standard Top end, bent Shifter fork and Clutch issues, bent caliper hanger, seized caliper piston, slightly bent yokes as it turns out from long ago, and the Dep Expansion pipe that is only 65% left in existence.

I also dented the tank very badly and cannot pull it out, it's trashed,

And the Power-valve which was 'fully sent'. It blew the remaining pin out the exhaust,, I think as the bottom end didn't grenade itself.It was doing 80mph in 5th gear and still pulling, so it was mission accomplished.

Full Yeet.

-

*Nobody

ME:

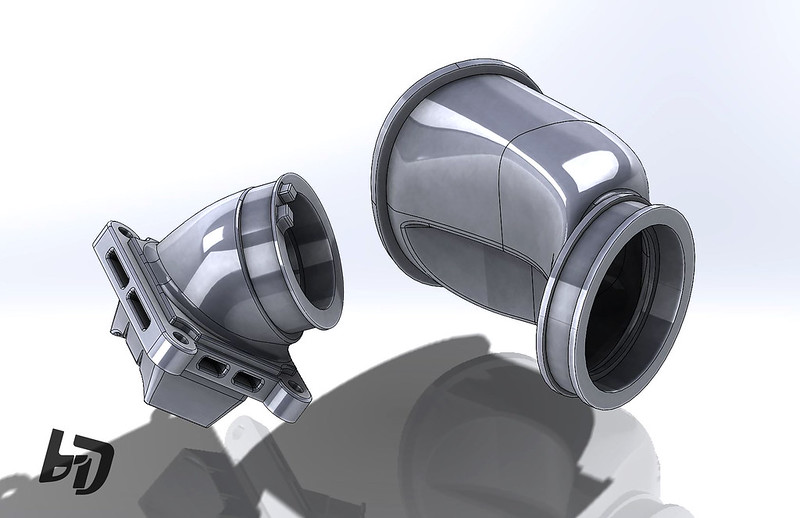

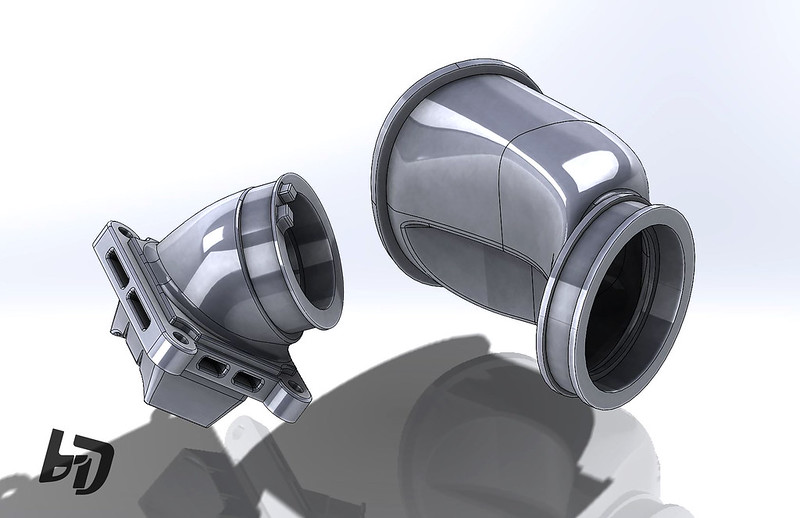

*A custom inlet tract for a DT125R.

Couple beers and some eyeballing and you can make whatever you want.

Getting to old for Pod filters and hacking shit bits together. So if you could, why not re-design OEM equipment in your favour?

Knocked these up on Solidworks to be a straight swap into the frame and Airbox.The brief, for my application, getting an inlet tract as straight as possible for 34mm or larger Carburettor to fit around my YZ490 shock, which is way larger than the original DTR unit.

Science bitch.

I have access to a 3D printer, so I've been designing and making prototypes just for a bit of fun after work,

Technology these days....,

-

*Nobody

ME:

*A custom inlet tract for a DT125R.

Couple beers and some eyeballing and you can make whatever you want.

Getting to old for Pod filters and hacking shit bits together. So if you could, why not re-design OEM equipment in your favour?

Knocked these up on Solidworks to be a straight swap into the frame and Airbox.The brief, for my application, getting an inlet tract as straight as possible for 34mm or larger Carburettor to fit around my YZ490 shock, which is way larger than the original DTR unit.

Science bitch.

I have access to a 3D printer, so I've been designing and making prototypes just for a bit of fun after work,

Technology these days....,

@Darty Would you be kind enough to send me the STL file for the intake manifold so i can 3d print this on my printer please buddy?

-

@Darty Would you be kind enough to send me the STL file for the intake manifold so i can 3d print this on my printer please buddy?

@Walney-Reptiles Yeh when I've made a working prototype I'll let you know bud,

-

@Walney-Reptiles Yeh when I've made a working prototype I'll let you know bud,

@Darty cheers, il have to edit it to fit my carb "When i get it"

-

Global pandemic huh? returns to shed

Not been doing alot, just wanted to share some bits.

After 4 years, finally built a proper DTX Brembo Caliper conversion. Threw some Titanium bolts on for some weight saving, and bling.

Custom Bracket and Spacers made, was fun on the old Myford Lathe. Got to force yourself to work in Imperial though...,

Plenty of braking power with Ceramic Pads on a 298mm Disc. To manage the DTR Fork, I've rebuilt them with 15W Oil and 35mm Spring Top Hat spacers, this effectively shortens the spring travel and keeps the spring in its stiffest part of the stroke. It works well enough for me at 70kg.

Could be better, but you can pedal this thing hard into mid corner so it feels pretty sorted for road use.

I've got a USD setup in bits currently, got a set off NOS 1996 YZ250 Forks, if anything, they just look sick.

I will do a Build thread on installing USD forks for the DTR, as I think many people want to do it but are not sure about the parts needed to do so.

Re-mounted my Ignitech CDI with rubber mounts and polished up my bracket, sadly it seems the company has disappeared. I've never had a problem with my unit and this Programmable CDI is the best thing I ever bought for this project.

The spark on this thing is ridiculously good.

I couldn't be bothered to fix my ported 3MB 'P' 134cc Cylinder so i went back to my old 14,000 Mile standard bore 3MB

Cylinder with a TDR unrestricted Head, and it has been so much fun to ride. Just a torqueey reliable DT engine like I remember it when I was 17.QUICK ENOUGH LOL

Been running different carbs for a few years now, and I have to say you couldnt do much better than well Setup Mikuni TM28ss and the 30ss from a WR200 is brilliant for the 125R.., depending on how good you can setup the floats and mixture.

This is the problem with any carburettor using the standard Inlet,

MIKUNI TM28SS - TM30SS - TM32 - TM34SS - KEIHIN PWK36

My favourite so far has been setting up a Mikuni TM34SS from a Aprilia RS250 and Later model RGV250s, (Same engine)

Mainly, the Venturi is angled so the Fuel Bowl remains level. But it has a really effective power jet and has been easy to setup, it works really well with just 125cc, this engine barks and pulls great at Mid-Range too. For me, I pretty happy keeping this engine under 140cc. It's plenty fun.

I'm using a Modified WR200 Inlet with Boyseen DT200R Reeds. Runs good.

I have a 3D printed Airbox to Carb boot I designed, so it's water tight and easier to jet than a Pod Filter.

Currently waiting to print a new filament that has the right Shore Hardness to produce a rubber part like the original. You need a good amount of flex to seat the airbox and carb together.

This has all been paired with old Nikkon Race exhaust, Handmade, Gas welded steel. There is pretty much no info on these.

I bought this from a guy who used it a couple of times and then stored it for 10 years, as far as I know this is the only DT125R Nikkon pipe left in existence. Which is a shame, because this pipe is so much better than the DEP on the road.

I'm going to copy this pipe into Stainless steel and just keep it the way it is because it suites my application so well. Very large expansion pipe aswell, the design is unique.

Will go further into the restoration of it as it's currently covered in BBQ Black paint.

Long term project aye, I've already had my fun.